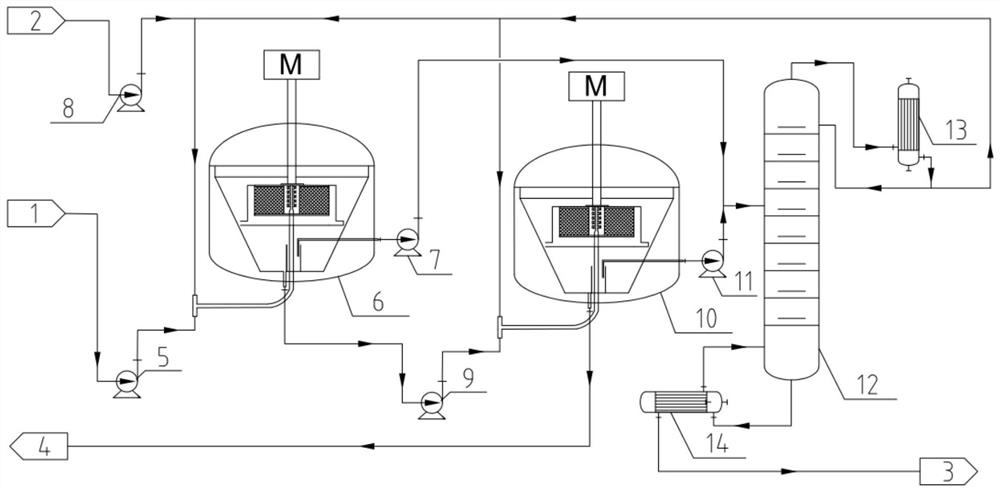

Continuous preparation system and method of cyclododecanone solution oxime

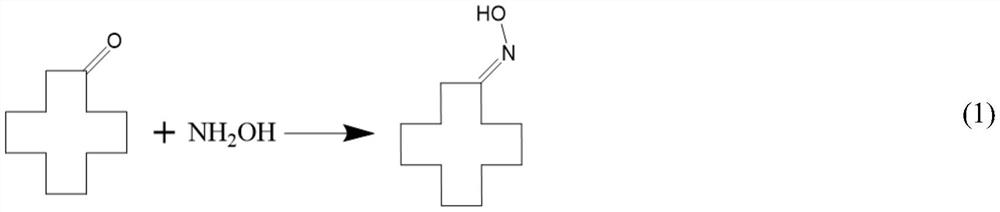

A technology of cyclododecanone and a preparation system, which is applied in the field of continuous preparation system, can solve the problems of reducing the utilization rate of hydroxylamine in the oximation reaction rate, hindering the release process of hydroxylamine, complicated side reactions in the rearrangement process, etc., so as to shorten the total production time. , The effect of eliminating additional solvent and suppressing side reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] Adopt the system and method of the present invention to produce cyclododecanone solution oxime, adopt the following operating conditions: the overall pH value of the feeding hydroxylamine sulfate salt solution has been pre-adjusted to 9 with ammonia water; Molar flow and the molar flow of the fresh feed cyclododecanone solution meet the stoichiometric ratio of the oximation reaction; the molar flow of hydroxylamine in the fresh feed hydroxylamine solution: the molar flow r of the cyclododecanone solution in the rectifying tower top reflux liquid =1:10; the temperature T in the two-stage high-gravity reaction phase separator is controlled at 95°C; the high-gravity level G of the rotating filled rotor in the two-stage high-gravity reaction phase separator is 400g; temperature t 1 Controlled at 260°C, its top temperature t 2 Controlled at 125°C; the residence time t of the fluid in the supergravity reaction phase separator s for 10 minutes. After the steady-state operat...

Embodiment 2~10

[0083] Embodiments 2 to 10: The technological process and steps are the same as in Embodiment 1, and the meanings represented by each letter in the header are also the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com