Substance for reducing TSNAs of flue-cured tobaccos with different maturity degrees, application and baking process

A technology of maturity and flue-cured tobacco, applied in the curing process and the field of tobacco curing, can solve the problem of no natural degradation method, and achieve the effects of improving the appearance quality and sensory quality of tobacco leaves, improving the quality of tobacco leaves, and reducing harm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

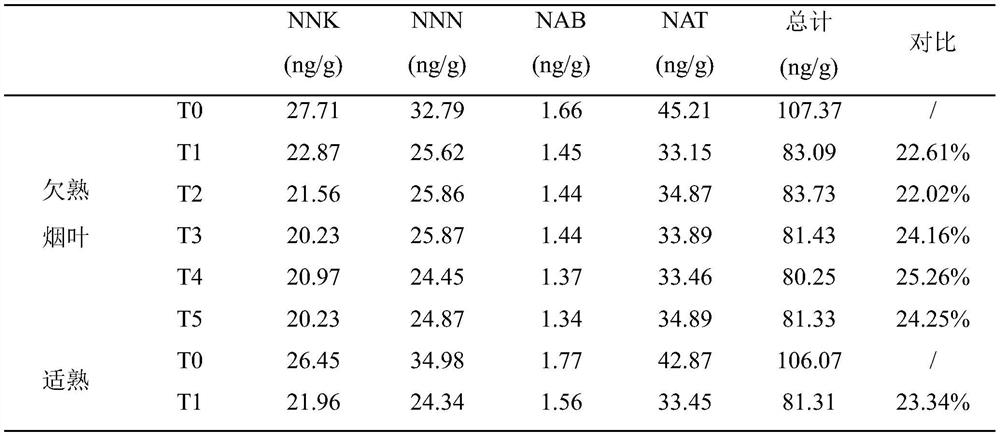

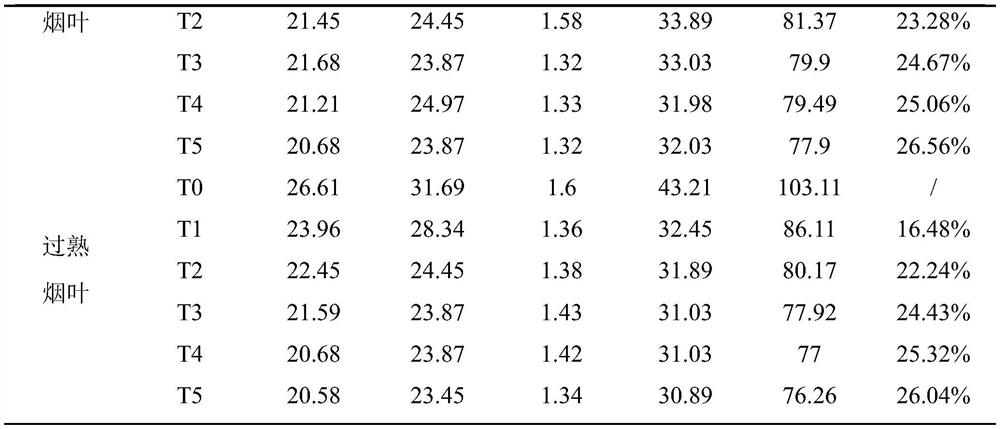

[0062] Influence of the curing process of the present invention on the content of TSNAs in NC102 tobacco leaves with different maturity

[0063] S100: Fresh NC102 flue-cured tobacco leaves of different maturity levels collected in Jiuxi Town, Jiangchuan District, Yuxi City, Yunnan Province. The mature fresh tobacco leaves have main veins that turn white and shiny, and branches that turn green and white. The leaves are greenish yellow or light yellow, and most of the hairs After falling off, it has the characteristics of rich e-liquid after touching it. Tobacco leaves picked and roasted 15 days before mature tobacco leaves were picked and roasted were regarded as underripe tobacco leaves. Tobacco leaves picked and roasted 15 days after mature tobacco leaves were picked and roasted were regarded as overripe tobacco leaves.

[0064] S200: classify the above harvested fresh tobacco leaves according to the amount of 90-110 pieces / stem for weaving and weaving the stems.

[0065] S...

Embodiment 2

[0079] Influence of spraying ascorbic acid solution of the present invention on relative conductivity and MDA content of NC102 tobacco leaves with different maturity after curing

[0080] According to Example 1, the changes in the relative electrical conductivity and MDA content of tobacco leaves with different maturity levels were measured at the end of the early yellowing stage and the late yellowing stage.

[0081] Table 3 Changes of relative conductivity and malondialdehyde content of NC102 flue-cured tobacco with different maturity (roasted in Hongyan Town, Midu County)

[0082]

[0083] It can be seen from Table 3 that after being treated with ascorbic acid solution, the changes in the relative conductivity of flue-cured tobacco leaves with different maturity levels are significantly different, and the content of MDA in the leaves is also significantly different, among which T4 and T5 treatments can reduce the relative conductivity and content of malondialdehyde, and ...

Embodiment 3

[0084] Example 3 Effect of the present invention's curing process on the content of TSNAs in KRK26 tobacco leaves with different maturity

[0085] S100: KRK26 flue-cured fresh tobacco leaves of different maturity levels in Xiaguan Town, Dali Prefecture, Yunnan Province. The mature fresh tobacco leaves have main veins that turn white and shiny, and branches that turn green and white. The leaves are greenish yellow or light yellow, and most of the hairs fall off. After that, it has the characteristics of rich smoke oil. Tobacco leaves picked and roasted 15 days before mature tobacco leaves were picked and roasted were regarded as underripe tobacco leaves. Tobacco leaves picked and roasted 15 days after mature tobacco leaves were picked and roasted were regarded as overripe tobacco leaves.

[0086] S200: classify the above harvested fresh tobacco leaves according to the amount of 90-110 pieces / stem for weaving and weaving the stems.

[0087] S300: Spray and inoculate evenly on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com