Oil inlet transverse cavity clamp for oil sprayer

An injector and transverse cavity technology, which is applied in the field of injector oil inlet transverse cavity fixtures, can solve the problem that the installation position and installation angle of the oil inlet transverse cavity cannot be adjusted, and the oil injection transverse cavity of different sizes and specifications cannot be solved. Installation positioning and other issues to achieve the effect of improving R&D and production efficiency, reducing economic costs and time costs, and reducing costs and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

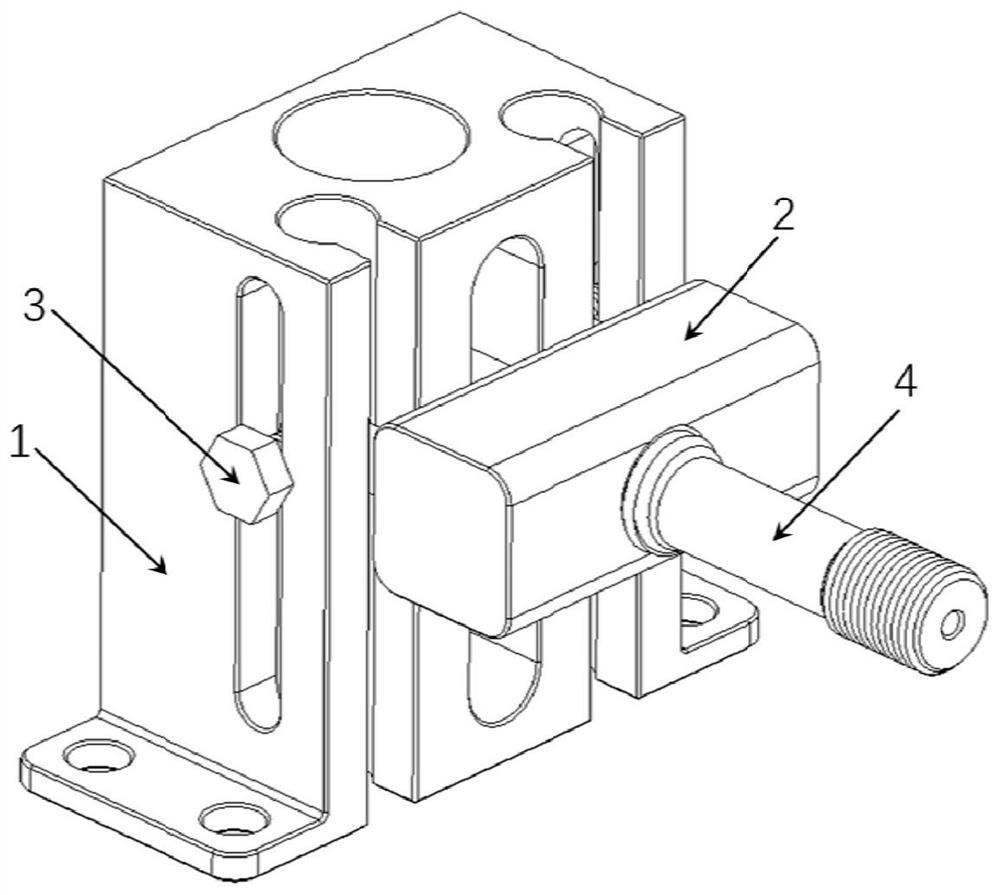

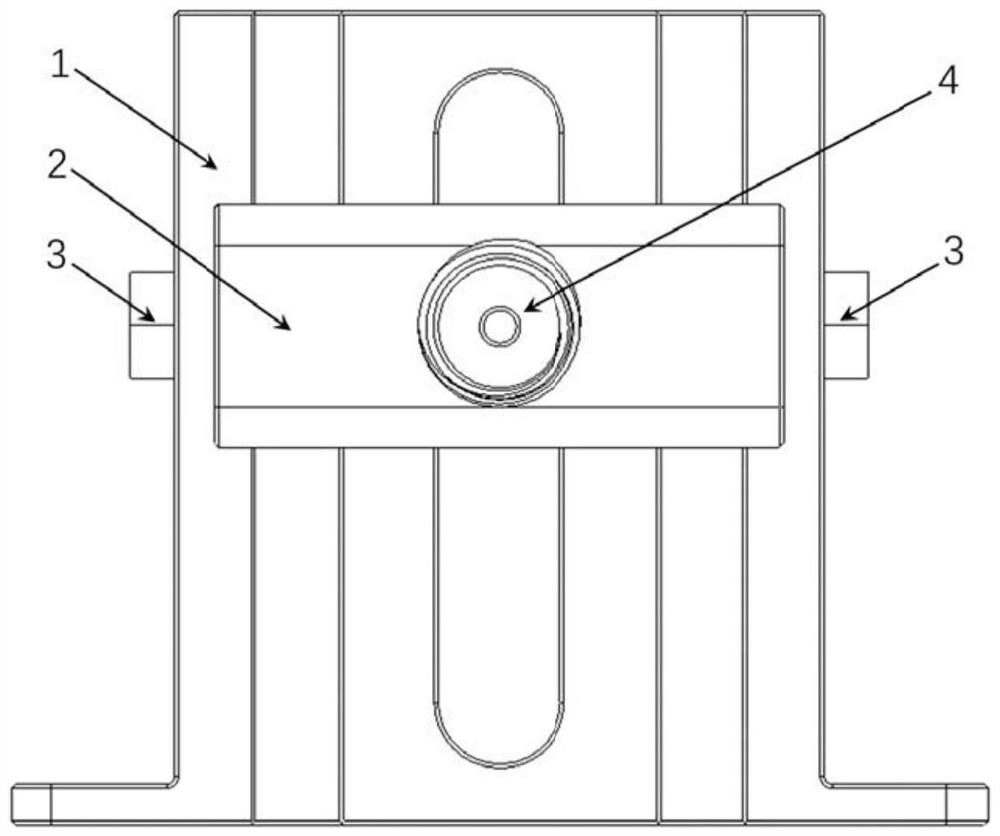

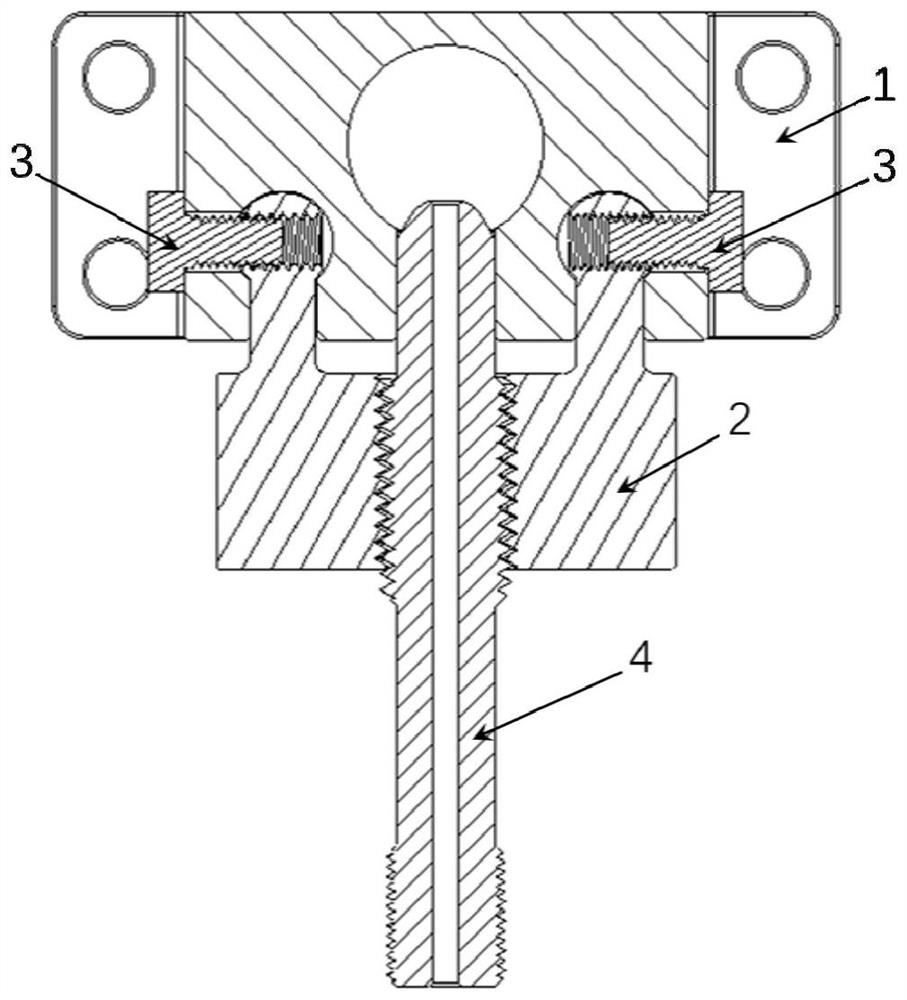

[0022] Below according to the accompanying drawings Figure 1 to Figure 9 , give a preferred embodiment of the present invention, and give a detailed description, so that the functions and characteristics of the present invention can be better understood.

[0023] see Figure 1 to Figure 9 , an injector oil inlet horizontal cavity fixture according to an embodiment of the present invention, including an injector mounting seat 1, a horizontal cavity mounting block 2, two fastening bolts 3 and a universal oil inlet horizontal cavity 4; The mounting base 1 is formed with a fuel injector mounting hole 11, two guide holes 12, two slotted holes 13 and a through groove along the vertical direction; Openings are formed at the front end; slots 13 are set on both sides of the injector mounting base 1 and communicate with the guide hole 12; the through groove is set between the two guide holes 12 and communicate with the injector mounting hole 11; universal oil inlet The cross chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com