Perforated stiffening rib-reinforced concrete combined steel beam and construction method thereof

A technology of reinforced concrete and stiffeners, applied in bridges, bridge materials, bridge construction, etc., can solve the problems of increased steel consumption, cost increase, and instability of the whole bridge, so as to reduce steel consumption, save engineering costs, The effect of improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the present invention will be clearly and completely described below in conjunction with the accompanying drawings, but the present invention can be implemented in various ways defined and covered by the claims.

[0028] The perforated stiffener-reinforced concrete combined steel girder involved in the present invention is welded on the bottom plate of the steel girder when the perforated stiffener is welded on the bottom plate of the steel girder, and at the same time transverse steel bars are interspersed in the opening of the perforated stiffener. After the beam erection is completed, concrete is poured on the base plate for construction.

[0029] The detailed structure is as follows:

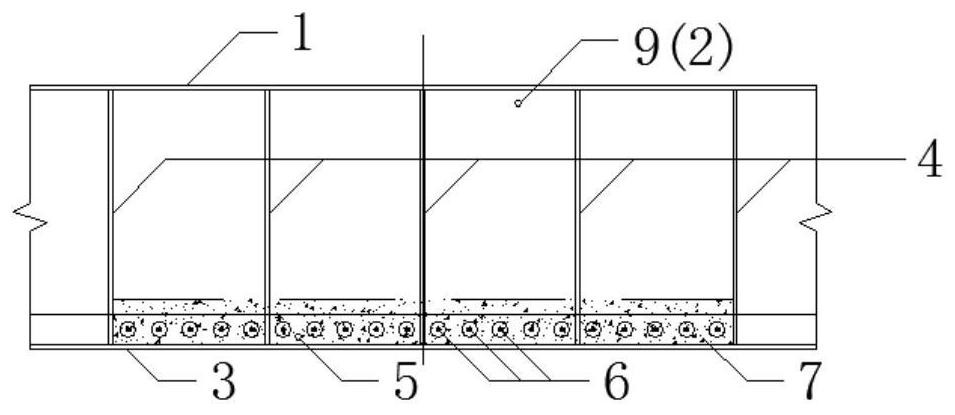

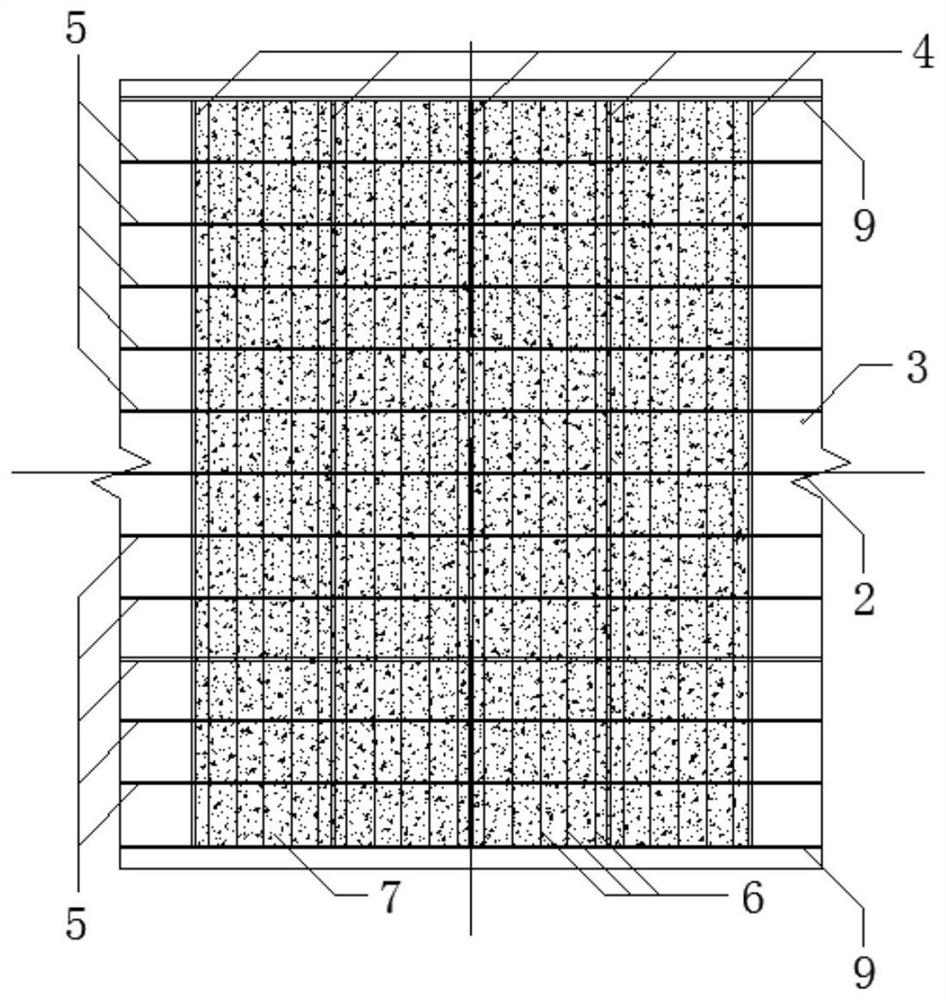

[0030] refer to figure 1 , figure 2 with image 3 , a perforated stiffener-reinforced concrete combined steel girder involved in the present invention is mainly composed of a top plate 1, a middle web 2, a side web 9, a bottom plate 3, a diaphragm 4, a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com