Novel light-emitting calibration device for automobile hub

An automobile wheel hub, a new type of technology, applied in the direction of wheels, wheel cover discs, vehicle parts, etc., can solve problems such as low practicability, complex structural design, traffic accidents, etc., to improve practicability, improve aesthetics, and improve practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

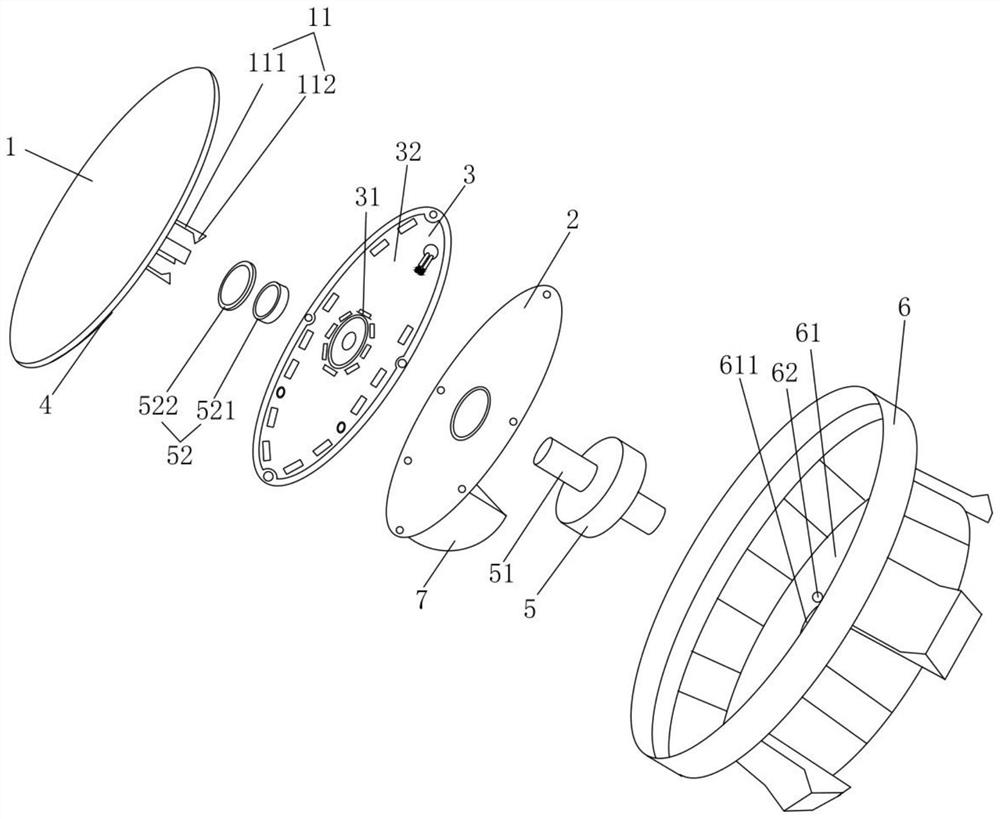

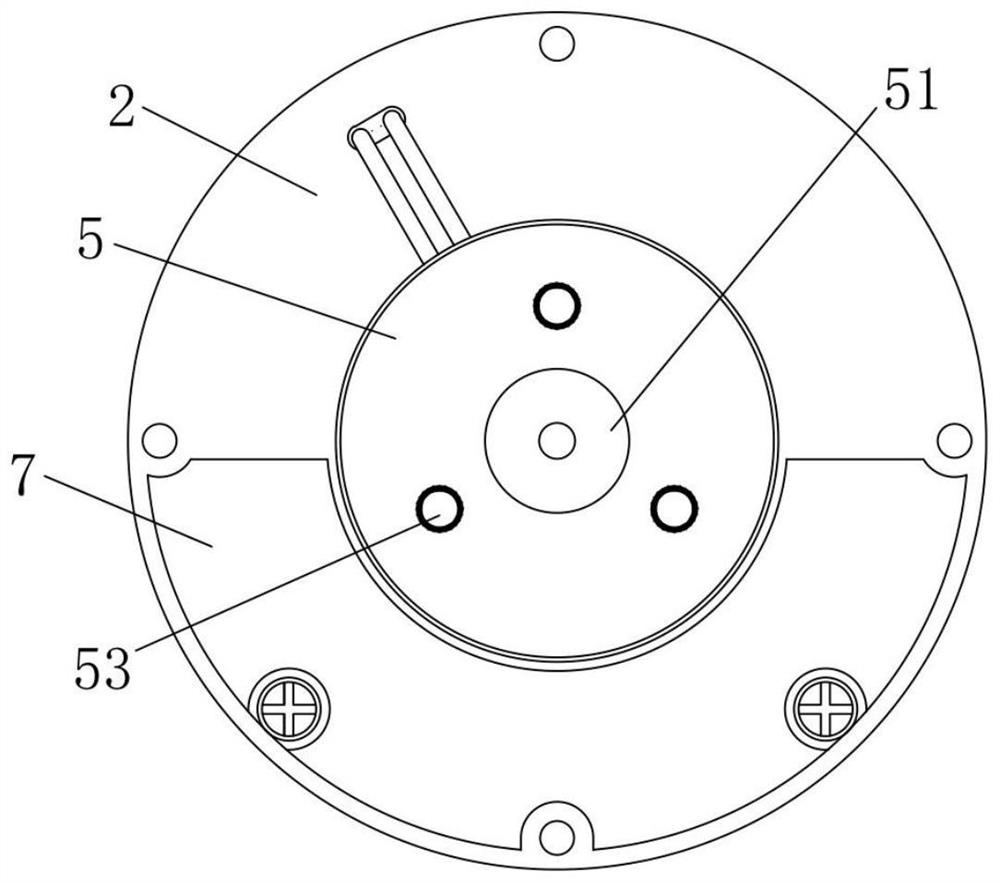

[0027] Please refer to Figure 1 to Figure 3 , the embodiment of the present invention provides a new type of light-emitting calibration device for automobile wheels, including a sign cover 1 arranged on the wheel hub, a fitting base plate 2 fastened on the inner side of the sign cover 1, and a fitting base plate 2 arranged on the fitting base plate 2. And a circuit board 3 located on the inner side of the sign cover 1, at least one first counterweight 4 arranged on the inner side of the lower part of the sign cover 1, is arranged on the side of the fitting base plate 2 away from the sign cover 1 and passes through the fitting base plate 2 and the circuit A motor 5 electrically connected to the board 3, and a casing 6 arranged on the side of the motor 5 away from the fitting base plate 2; the motor 5 is provided with a central shaft 51, and one end of the central shaft 51 passes through the fitting base plate 2 and is arranged There is a first bearing assembly 52, the first be...

Embodiment 2

[0039] In the first embodiment, the structure of a novel light-emitting calibration device for an automobile wheel hub is described. In this embodiment, differences from other embodiments are mainly described, and the same structure will not be repeatedly described in this embodiment.

[0040] The main difference between the second embodiment and the first embodiment is that the second counterweight 7 is not set on the matching bottom plate 2, the first fixing hole 62 is not set around the through hole 611, and the motor 5 is not set with the first fixing hole 62. A fixing hole 62 corresponds to at least one second fixing hole 53 , and the motor 5 is not fixedly connected to the housing 6 .

[0041] Such as Figure 4 with Figure 5 As shown, in this embodiment, the motor 5 is provided with at least one third counterweight 8 . By arranging the third counterweight 8, the motor 5 remains in a relatively stable state due to the action of the third counterweight 8 while the auto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com