Easy-to-maintain coating mixing and proportioning device

A technology that is easy to maintain and paint, applied in the direction of mixers, mixers with rotating stirring devices, mixer accessories, etc., can solve problems such as adding too much or too little additives, poor proportioning effect, additives that cannot be proportioned with raw materials, etc. Achieve the effects of improving uniformity, fast proportioning, and promoting technological development

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

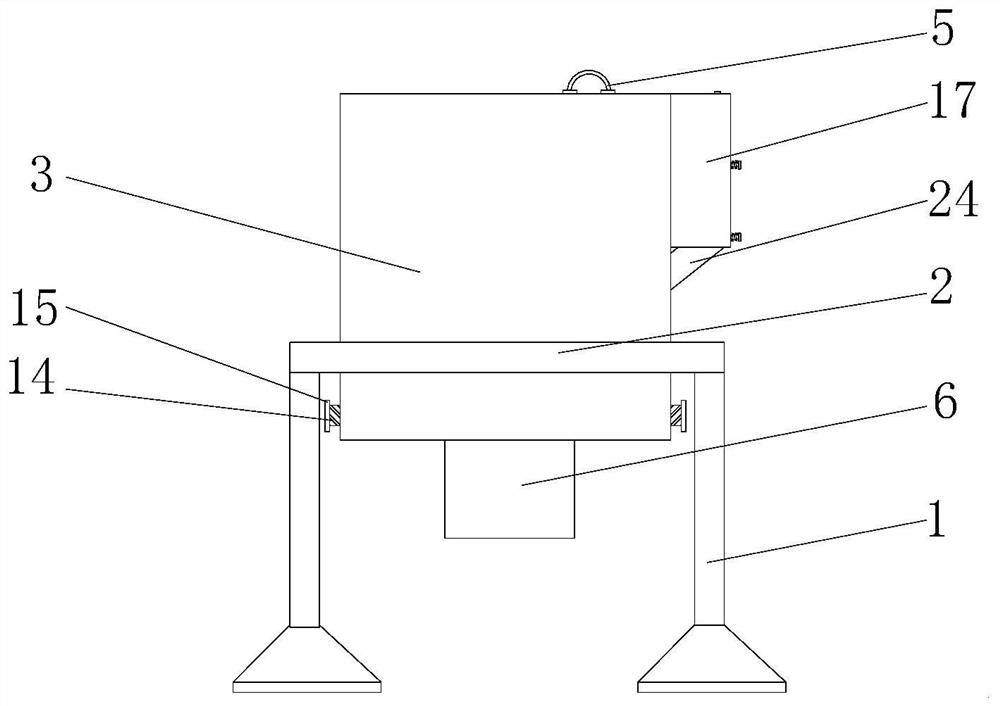

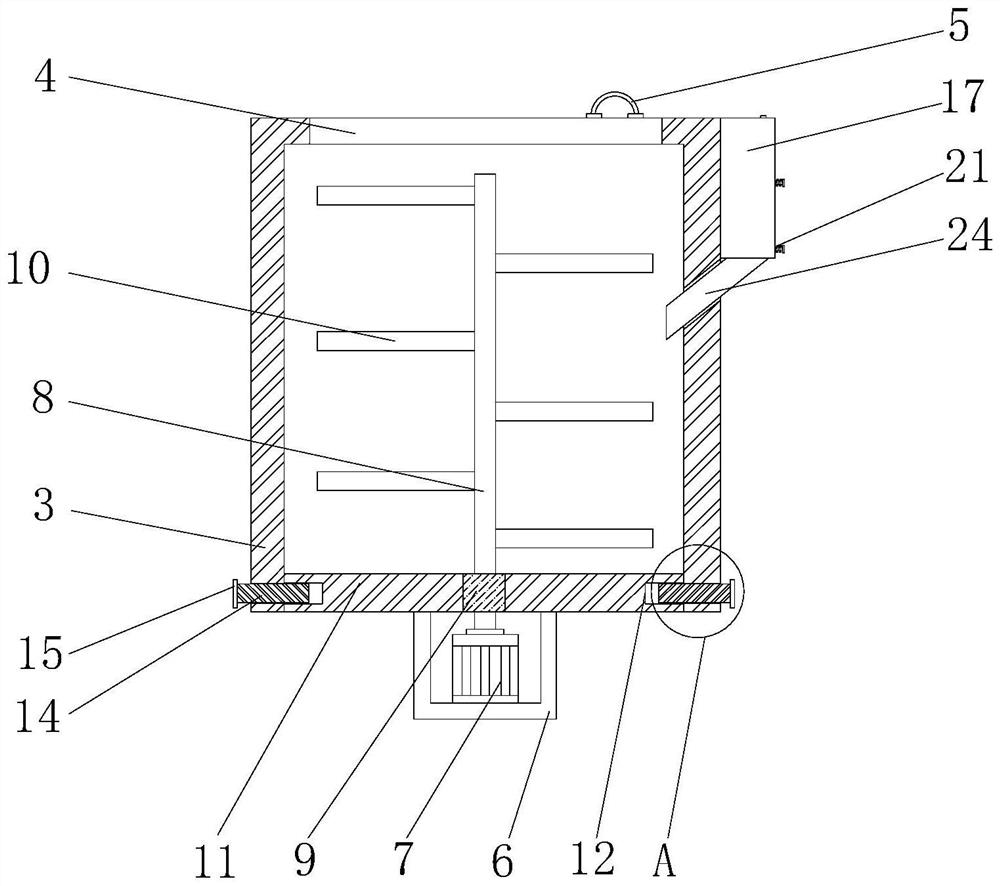

[0030] The preferred embodiment of the continuous stamping device for stainless steel products provided by the present invention is as follows: Figure 1 to Figure 7 Shown: a paint mixing and proportioning device that is easy to maintain, including a frame 1, the top of the frame 1 is fixedly connected with a connecting plate 2, the inner wall of the connecting plate 2 is fixedly connected with a proportioning box 3, and the bottom of the frame 1 is The triangular support frame increases the contact area between the frame 1 and the ground, thereby making the support for the proportioning box 3 more firm, increasing the stability of the device, and the proportioning box 3 will not fall over during work , the top of the proportioning box 3 is movably connected with a door 4, the top of the door 4 is fixedly connected with a handle 5, the door 4 can be opened by using the handle 5, and the surface of the handle 5 is fixedly connected with a non-slip mat, which can play a role in p...

Embodiment 2

[0033] On the basis of Example 1, the preferred embodiment of the continuous stamping device for stainless steel products provided by the present invention is as follows Figure 1 to Figure 7 As shown: the top of the rotating rod 8 runs through the bearing 9 and extends to the inside of the proportioning box 3, and the outer wall of the rotating rod 8 is fixedly connected with the inner wall of the bearing 9, and then when the motor 7 starts, the output end of the motor 7 passes through the shaft coupling Drive the rotating rod 8 to rotate, so that the stirring rod 10 can stir the raw materials on the inner wall of the proportioning box 3, so that the raw materials inside the proportioning box 3 can be fully stirred.

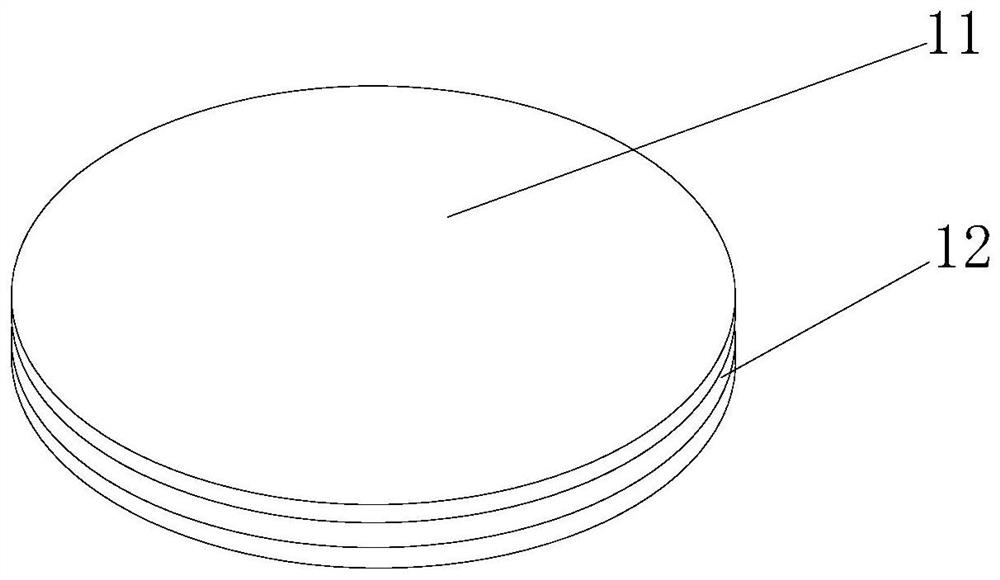

[0034] In this embodiment, one end of the threaded rod 14 extends to the inside of the limiting groove 12, and the surface of the threaded rod 14 is movably connected with the inner wall of the limiting groove 12, and then one end of the threaded rod 14 limits th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com