Single-air-duct cotton picking head with high picking net rate

A technology with high harvesting rate and cotton picking head, which is applied in the direction of picking machines, agricultural machinery and implements, etc., and can solve the problems affecting the normal operation, maintenance, cleaning, and life reduction of other related components of cotton picking machines. Complex structure and other problems, to achieve the effect of simple structure, improved stability and flexible use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and advantages of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and examples. It should be understood that the specific embodiments described here are only used to explain the present invention, not to limit the present invention.

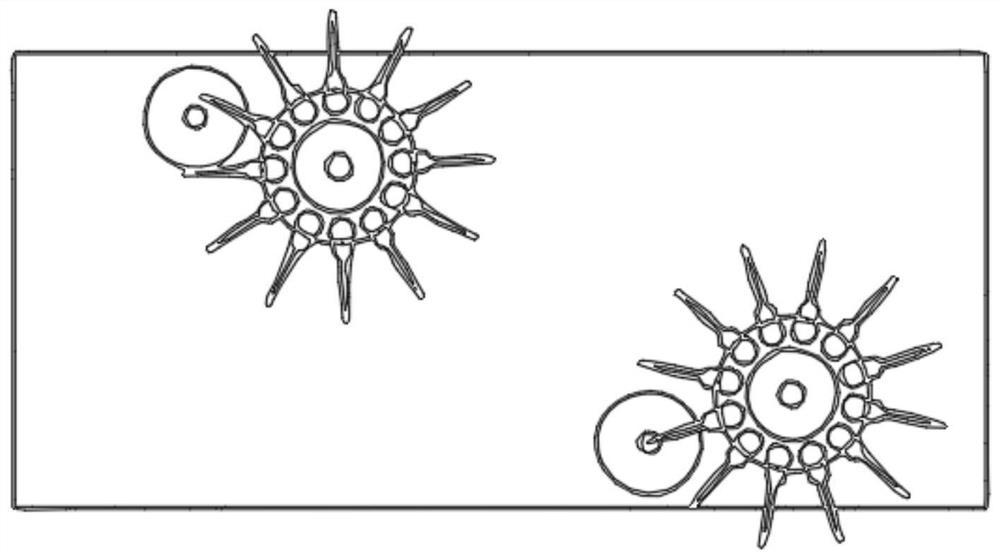

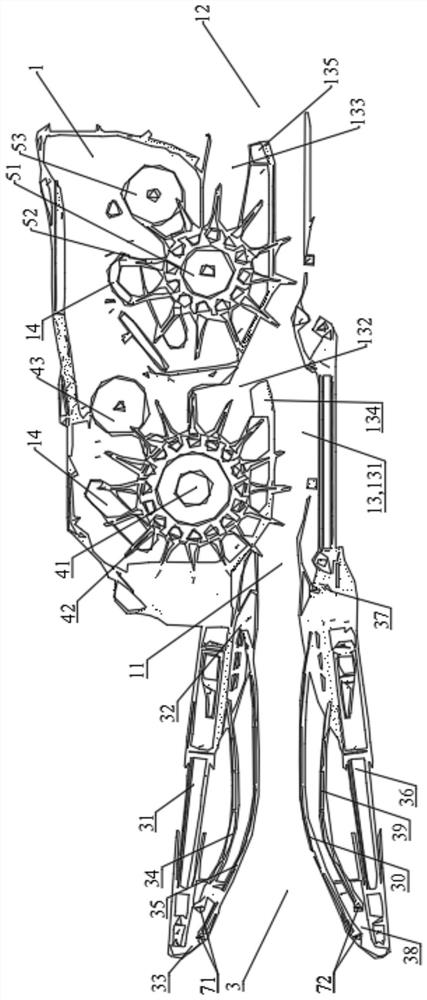

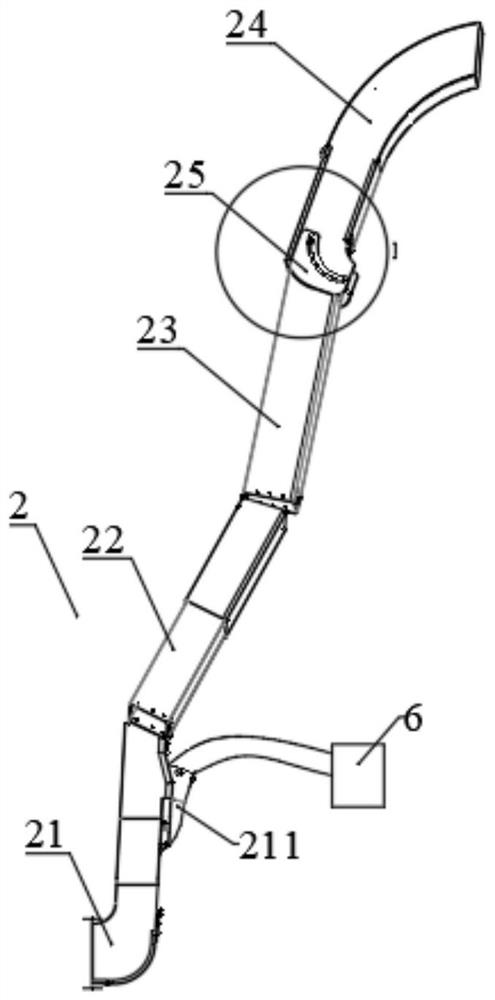

[0028] refer to figure 2 , image 3 , Figure 4 , a single-air-channel cotton picking head with a high recovery rate, comprising a casing 1, one side of the casing 1 is a feed inlet 11 and a feed passage 3 communicated with the feed inlet 11, the casing 1 On the same horizontal plane on the other side, a discharge port 12 and a discharge air duct 2 communicating with the discharge port 12 are arranged; a first roller 41 and a second roller 51 are arranged horizontally inside the casing 1, and the first A number of first picking spindles 42 are evenly distributed on the drum 41, and a number of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com