Traction and electric power hybrid power supply system for alternating current electrified rail transit engineering

A technology for rail transit engineering and power supply system, which is applied to AC network circuits, electrical components, power supply lines, etc., and can solve the problems of not too high driving speed, high difficulty, and unbalanced influence of the three-phase power supply system of the power grid. Voltage hazards, reduced speed loss, effect of reduced number of settings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

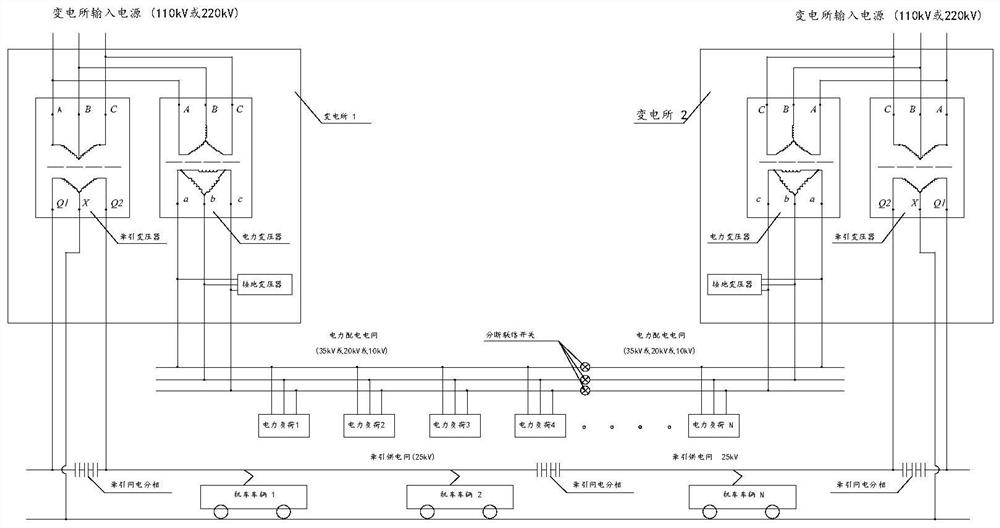

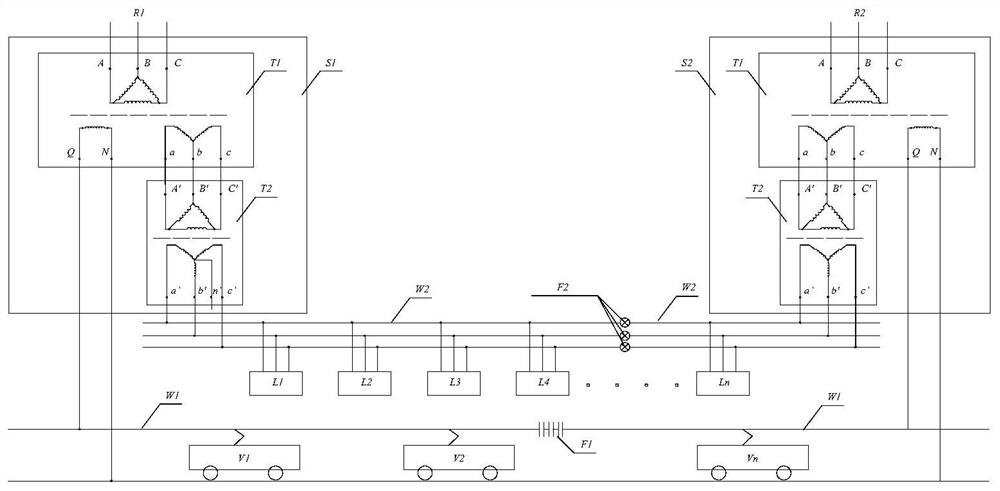

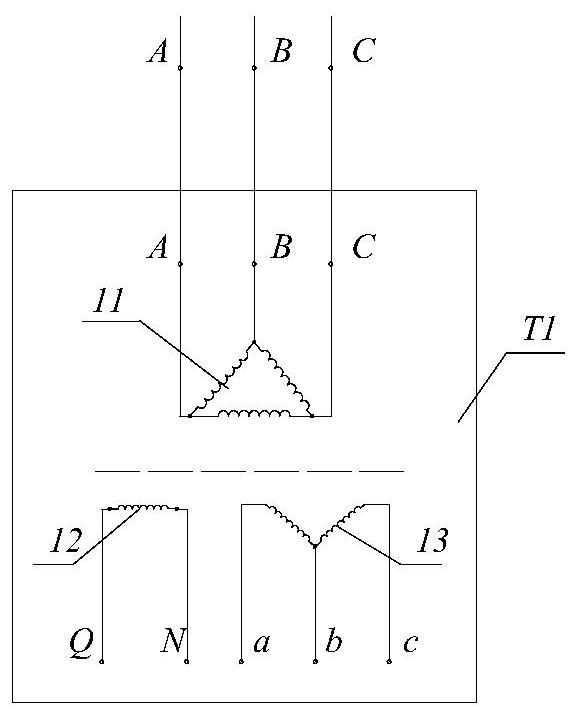

[0027] refer to figure 2, a kind of AC electrified rail transit project of the present invention is used traction and electric hybrid power supply system, two adjacent substations (S1, S2) introduce the input power supply (R1, R2) of 110kV or 220kV of substation respectively from the local grid ), its three-phase line is respectively connected to the traction winding and power winding on the high-voltage side of the three-phase traction and power hybrid transformer T1, and the 27.5kV single-phase traction power is output through its low-voltage side winding to connect with the 25kV traction power supply network W1, and the output three-phase The 35kV / 20kV / 10kV power supply is connected to the primary transformer of the three-phase isolation transformer T2 with a transformation ratio of 1:1, and the output three-phase 35kV / 20kV / 10kV power distribution power supply is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com