Full-automatic low-voltage reactor iron core binding machine

A low-voltage, fully automatic technology, applied in the manufacture of inductors/transformers/magnets, circuits, electrical components, etc., can solve problems such as low work efficiency, less or more latte sheets, etc., to achieve good wrapping quality and strong versatility , the effect of high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and through specific implementation methods.

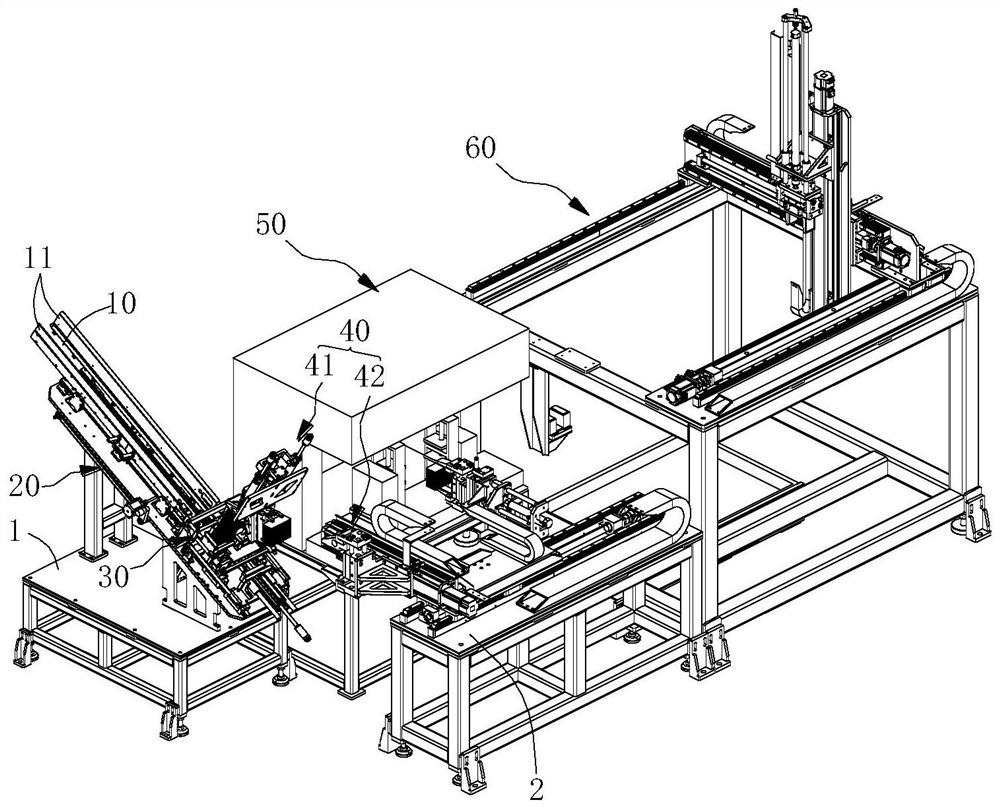

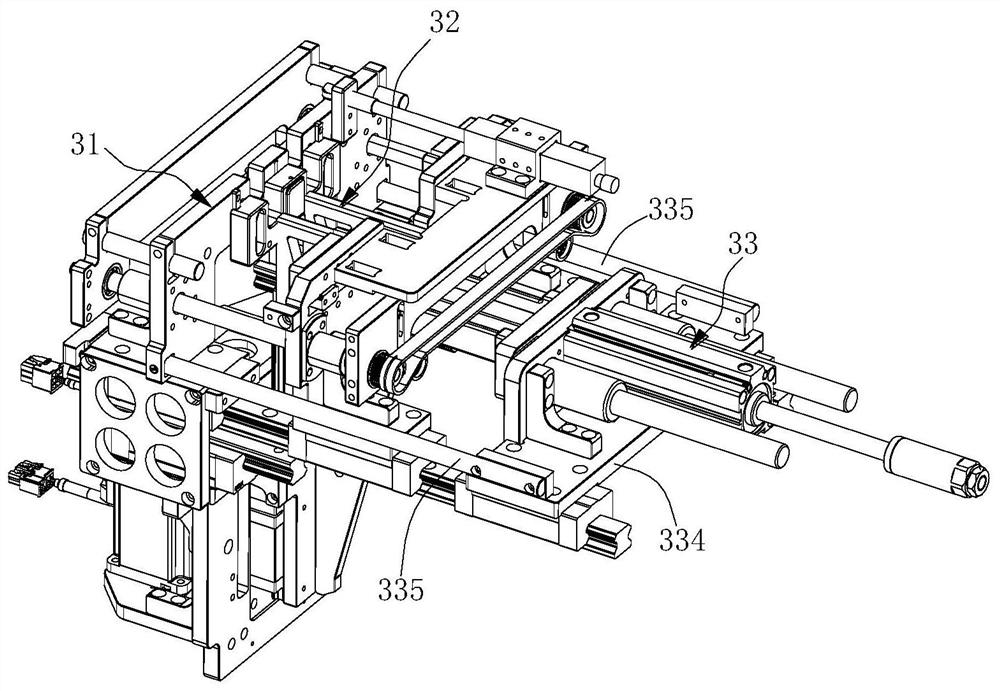

[0051] Such as figure 1 As shown, a fully automatic low-voltage reactor iron core wrapping machine includes a material channel 10 inclined downwardly arranged on a material rack, a material plate driving mechanism 20, a material cutting mechanism 30, a loading and unloading mechanism 40, a tape winding machine 50 and Palletizing mechanism 60; wherein, the material path 10 is composed of two material plates 11 relatively arranged on the material rack 1, and is used to transport the iron sheets in sequence; the material plate driving mechanism 20 is used to drive the two material plates 11 to move toward each other; The material cutting mechanism 30 is located at the lower end of the material channel 10, and is used for cutting the iron sheets located in the material channel 10; , and after the iron ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com