Buffer seal for hydraulic breaking hammer

A hydraulic breaker and buffer seal technology, applied in the direction of engine seals, engine components, mechanical equipment, etc., can solve the problems of easy deviation in temperature and pressure control, unstable performance indicators, performance differences, etc., to increase the ability to withstand high pressure. capacity, extended cushioning performance, and the effect of avoiding maximum stress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

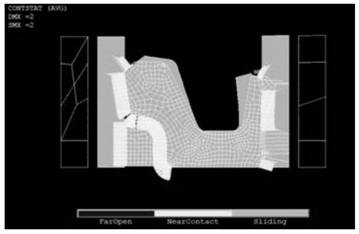

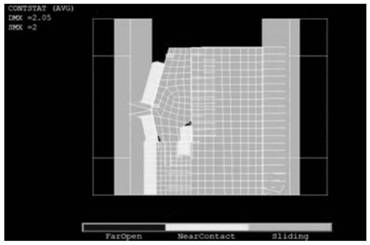

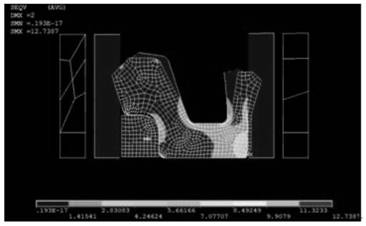

[0029] The following combination Figure 1 to Figure 11 The principles and features of the present invention are described, and the examples given are only used to explain the present invention, and are not used to limit the scope of the present invention.

[0030] A buffer seal for a hydraulic breaker, comprising a base body 1, an adjustment ring 2, and a buffer ring 3; The outer surfaces are respectively attached to the inner surfaces of the base body 1, and the adjustment ring 2 and the buffer ring 3 are distributed up and down, the buffer ring 3 is close to the high-pressure oil chamber, and the adjustment ring 2 is far away from the high-pressure oil chamber; the buffer ring 3 The inner cavities at both ends are respectively provided with a first bevel 4 and a second bevel 5 formed by inner chamfering. Define the angle between the first slope 4 and the axial direction as the oil surface angle, that is, the attached Figure 4 In α; define the angle between the second slo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com