Filter element for a filter unit

A technology of filter element and filter unit, which is applied in the direction of filtration separation, membrane filter, fixed filter element filter, etc., and can solve the problems affecting the deformability of the frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

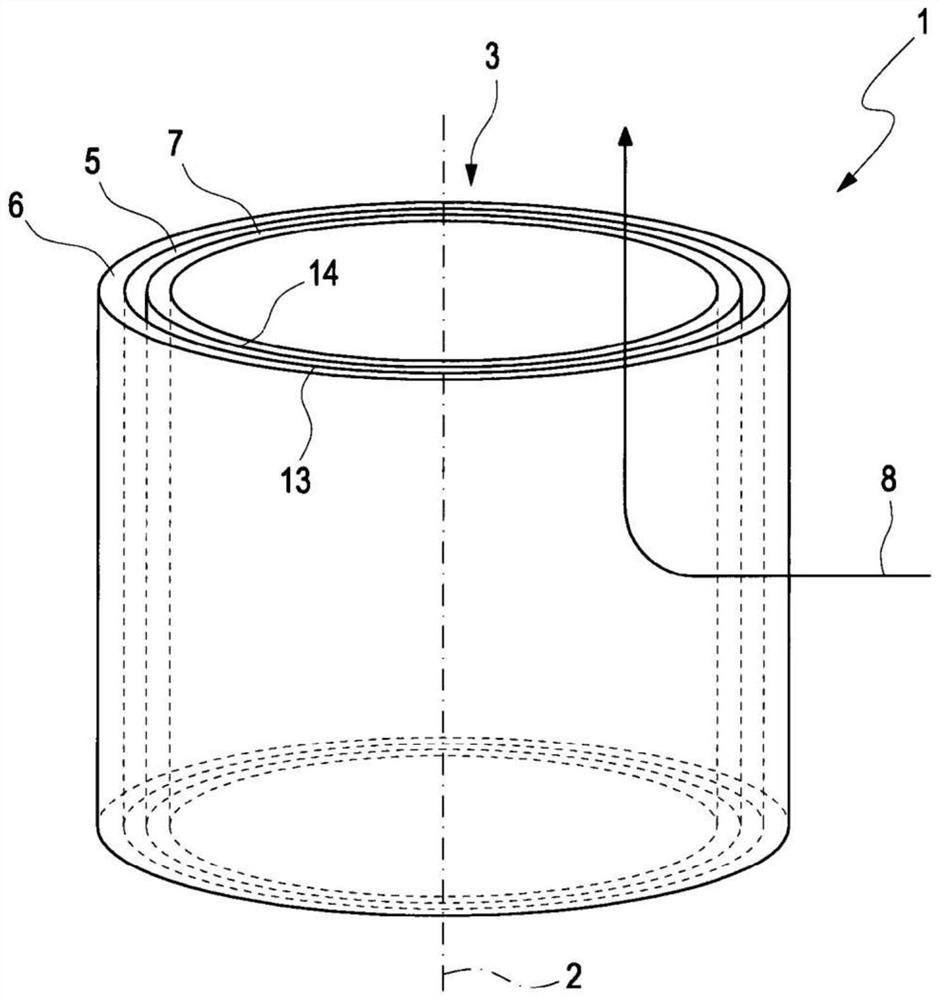

[0045] figure 1 A cylindrical filter element 1 is shown, the filter element body 3 of which is formed by a support body 5 and structures 6 , 7 . In the case of the filter element 1 , corresponding coaxial and concentrically positioned hollow cylindrical structures 6 , 7 are arranged on the inner region 14 and the outer region 13 of the support body 5 . Here, a flow 8 of fluid through the filter element 1 takes place, for example from the outside of the hollow-cylindrical filter element 1 into the inner region of the hollow-cylindrical filter element 1 , whereby the fluid is then guided further substantially parallel to the central axis 2 . Of course, instead of the hollow cylindrical filter element 1 , any desired geometry of the filter element 1 with the structure 6 and the support 5 can be used. Here, flat and / or cuboidal filter elements 1 are preferably used.

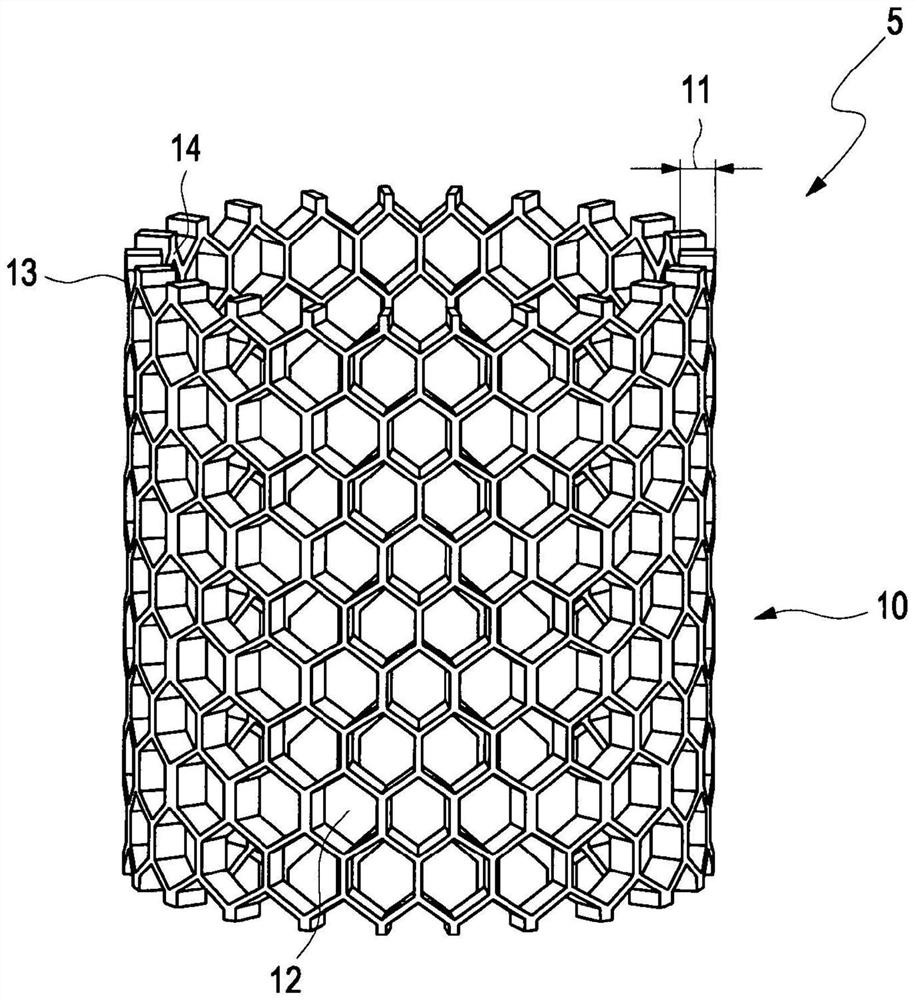

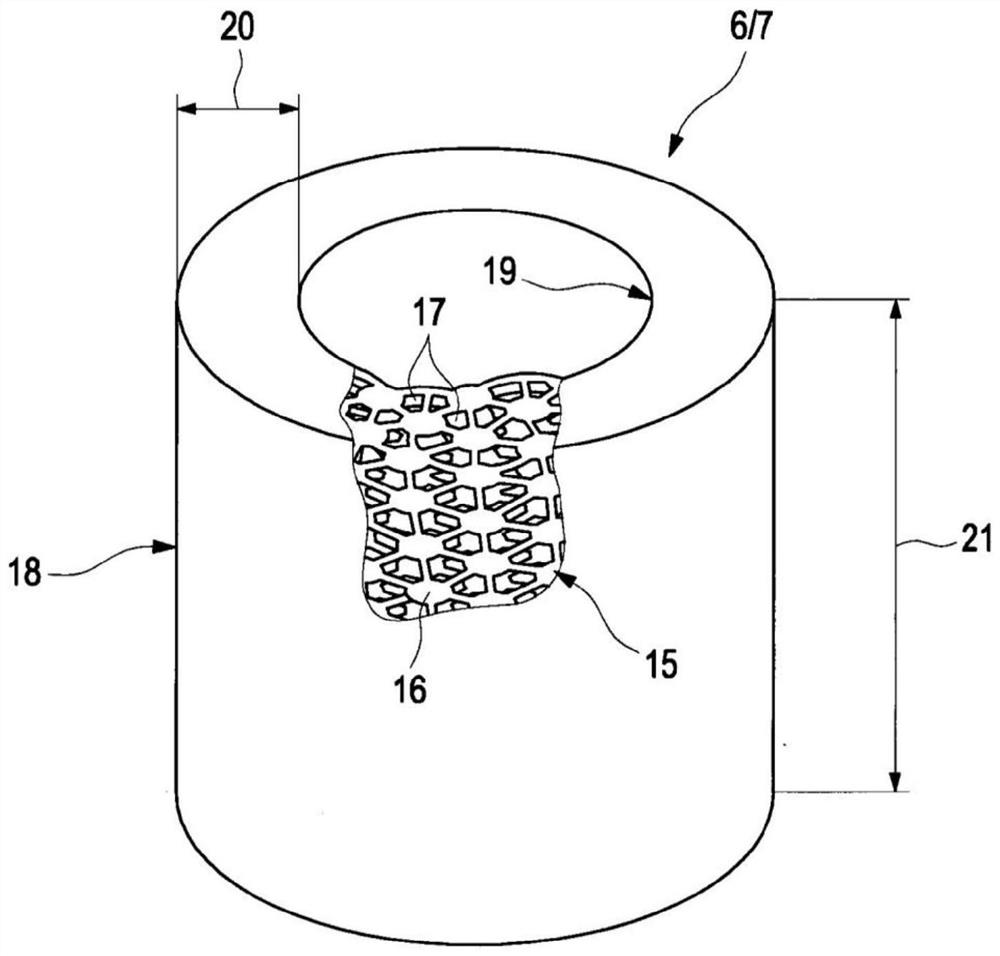

[0046] The outer structure 6 is built as a three-dimensionally interconnected lattice structure 15 and is produc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com