Debugging method of air balance system of airplane paint spraying hangar

A technology of balancing system and debugging method, which is applied in spray booths, spraying devices, etc., can solve the problems of less involved wind balance system debugging method, unclear debugging steps, and high cost of painting failure, so as to achieve a simple and clear debugging process and debugging. Simple process and clear thinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0079] A method for debugging an aircraft painting hangar wind balance system, comprising the following steps:

[0080] Step 1, installation inspection: check the installation of the wind balance system and check its function;

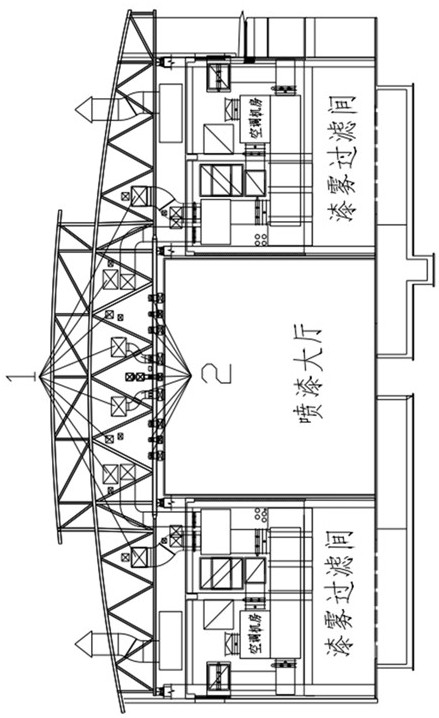

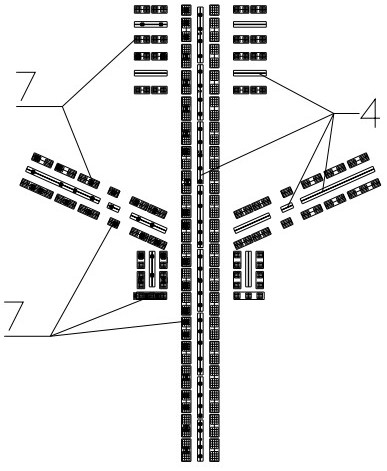

[0081] Step 2, commissioning preparation: install air volume test holes on the air duct of the air balance system, the air duct includes main pipe 1 and branch pipe 2, and determine the distance of the test hole according to the size of the air duct;

[0082] Step 3, adjust the total air volume of the unit: measure the total air volume of the unit in the air balance system through the air volume test hole in step 2, determine the frequency of the unit and adjust the total air volume of the unit;

[0083] Step 4, adjustment of supervisor 1: According to the data obtained in step 3, adjust the electric valves of each supervisor 1, and finally achieve the air volume balance of supervisor 1;

[0084] Step 5, end adjustment of branch pipe 2: measure the da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com