Raw material adding device for synthetic resin processing

A technology of synthetic resin and adding device, applied in the direction of feeding device, mixer with rotary stirring device, mixer, etc., can solve the problems of waste of human resources, reduce the efficiency of synthetic resin, increase the cost of synthetic resin, etc., to reduce labor The effect of strength, improving production efficiency, and controlling the amount of addition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

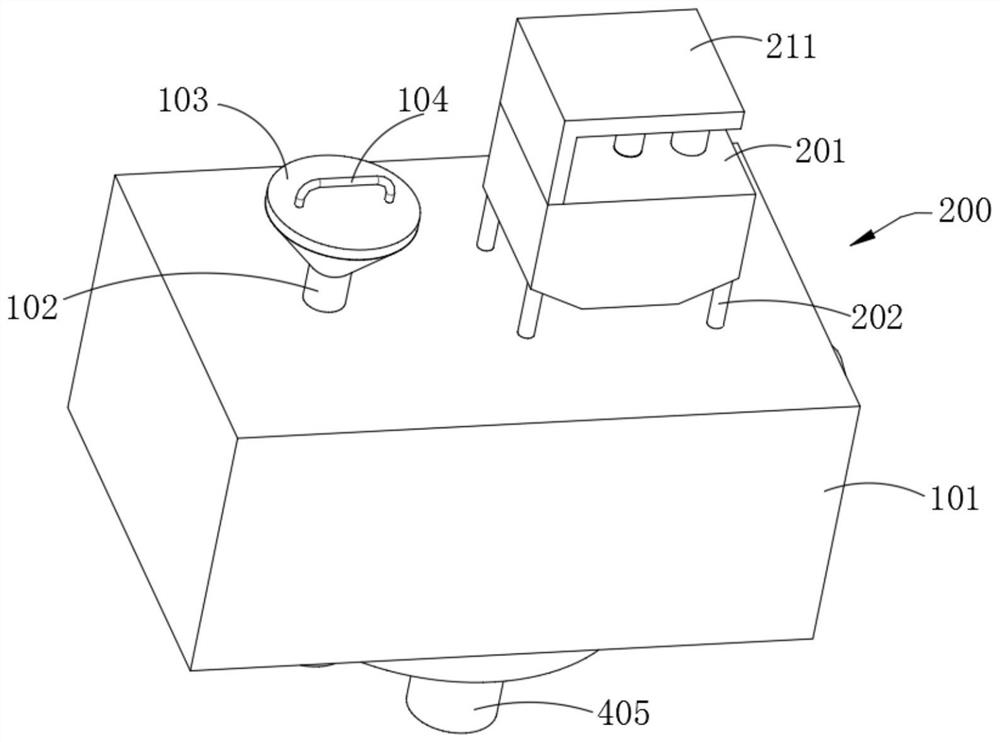

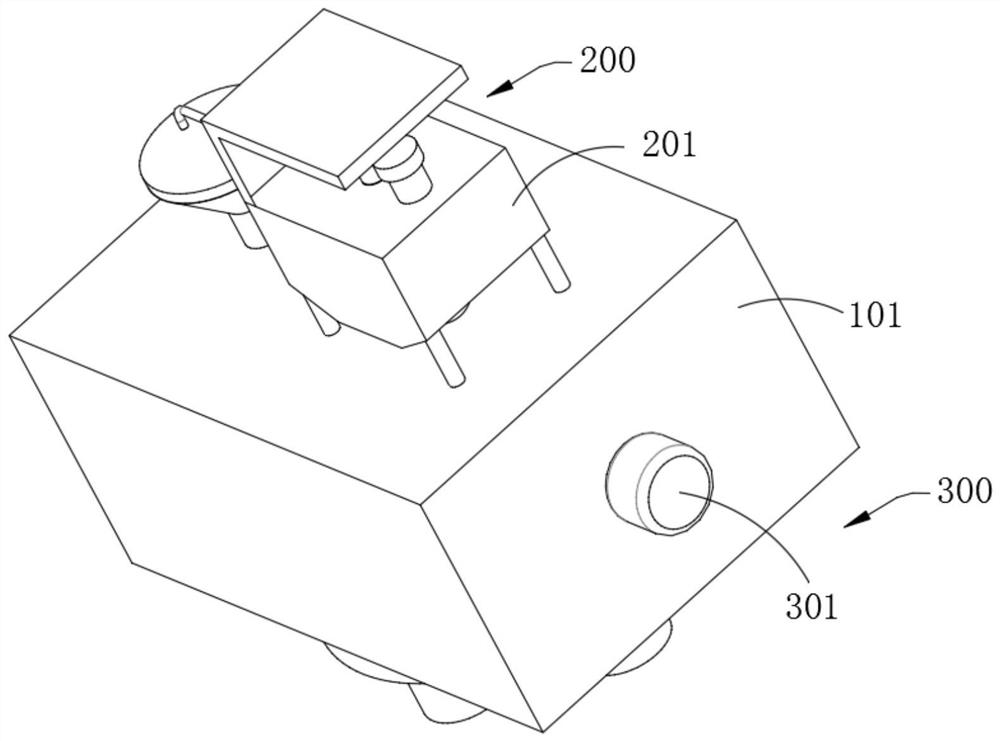

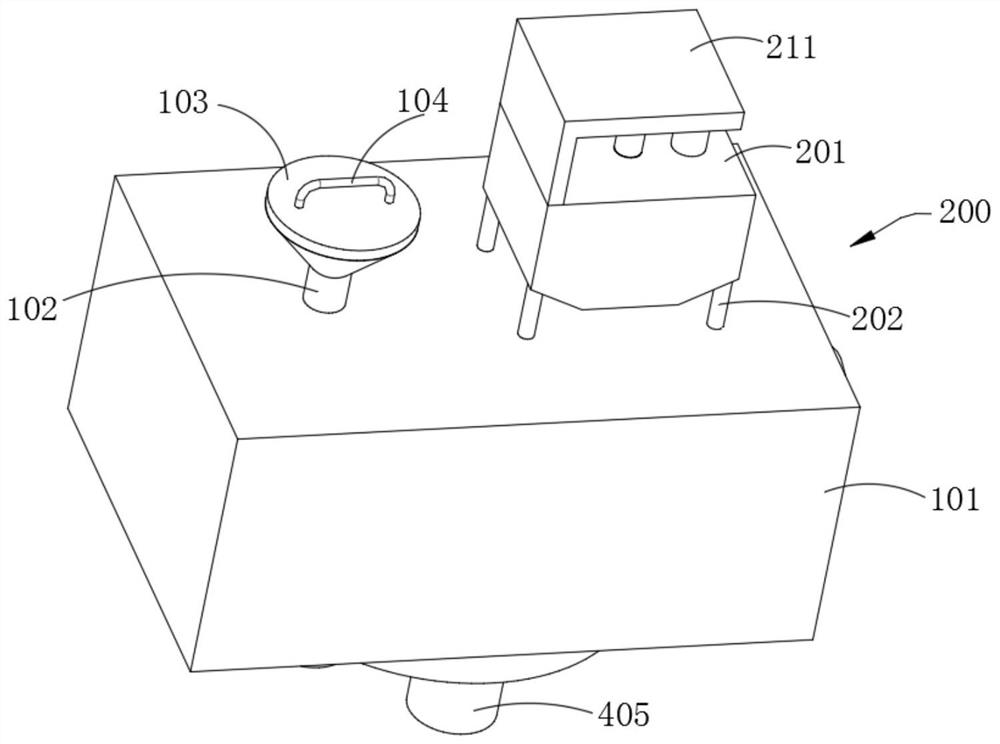

[0026] see Figure 1-6 , the present invention provides a technical solution: a raw material adding device for synthetic resin processing, including a collection box 101, the inner cavity of the collection box 101 is a cylindrical chamber, which is beneficial to ensure the uniformity of raw material stirring, and the collection box The top of 101 is provided with a water inlet mechanism 200, and the top side of the collecting box 101 is fixedly connected with a feed hopper 102, and the top of the feed hopper 102 is provided with a cover plate 103, and the top of the cover plate 103 is fixedly equipped with a handle 104. Hold the handle 104 to remove the cover plate 103 , and add raw materials to the inside of the collecting box 101 through the feeding hopper 102 , and the inside of the collecting box 101 is provided with a stirring mechanism 300 .

[0027] The bottom of the collection box 101 is provided with a quantitative discharge mechanism 400, the quantitative discharge m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com