Battery compartment applied to electric glue squeezing gun

A battery compartment and glue gun technology, applied in the field of battery compartments, can solve problems such as opening and closing of heat sinks, large power consumption, damage to battery compartments, etc., to prevent damage to electrical components, increase thermal conductivity, and increase air pressure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0027] Example

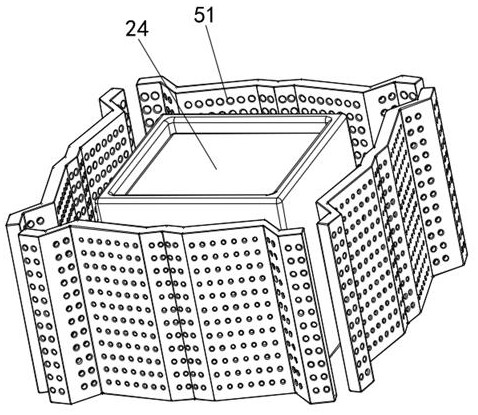

[0028] see Figure 1-7, a battery compartment applied to an electric glue extrusion gun, including a cover plate 1 and a motor 9, a main body assembly 2 is provided on the underside of the cover plate 1, and a detection assembly 3 is installed movable inside the upper side of the main assembly 2, and the detection assembly 3 Including an airbag 31, the upper side of the airbag 31 is provided with a push block 32, the outer side of the push block 32 is provided with a first spring 33, and the lower side of the main body assembly 2 is movably installed with a movement assembly 4, which includes a circular shell 22 The second spring 41 that is fixedly connected, the right side of the second spring 41 is fixedly connected with a swing lever 42, the upper side of the swing lever 42 is fixedly connected with a connecting shaft 43, the inner side of the swing lever 42 is provided with a rotating block 44, the output of the motor 9 The end is fixedly connected with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com