Method for detecting mixing uniformity of hydroxychloroquine sulfate particles

A technology of hydroxychloroquine sulfate and mixing uniformity, which is applied in the field of detecting the mixing uniformity of hydroxychloroquine sulfate particles, can solve the problems that are not conducive to improving production efficiency and cannot measure the detection results, and achieve fast and accurate mixing uniformity of hydroxychloroquine sulfate particles , high safety factor, fast and accurate detection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The detection method of embodiment 1 hydroxychloroquine sulfate particle mixing uniformity

[0041] (1) Add the hydroxychloroquine sulfate granules in the three-dimensional mixing tank, start the three-dimensional mixing tank, make the hydroxychloroquine sulfate particles fully contact with the inner wall of the three-dimensional mixing tank; then add magnesium stearate to avoid sticking the magnesium stearate on the three-dimensional mixing tank The inner wall; get the mixture, the batch is PAT190806-3.

[0042] (2) The near-infrared spectrometer is set on the sampling window of the three-dimensional mixing tank, and when the three-dimensional mixing tank is started, the near-infrared spectrometer and the three-dimensional mixing tank rotate synchronously.

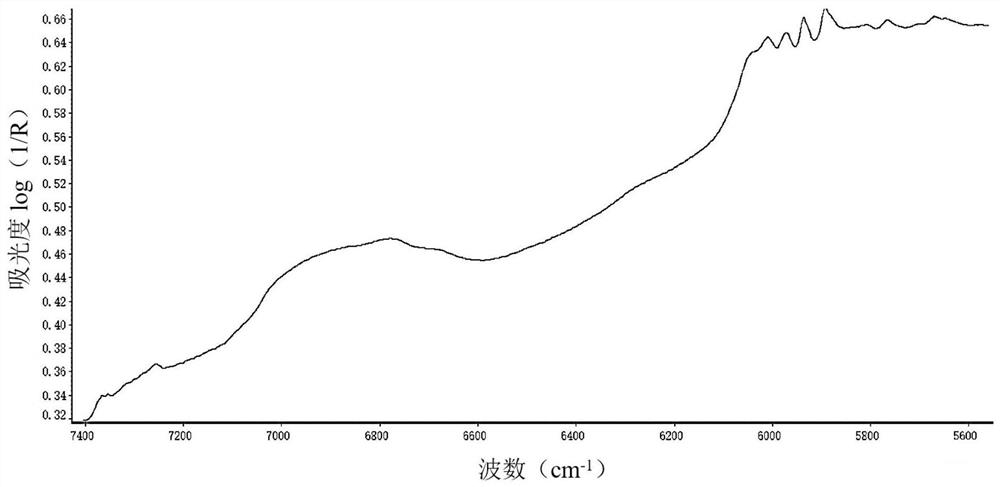

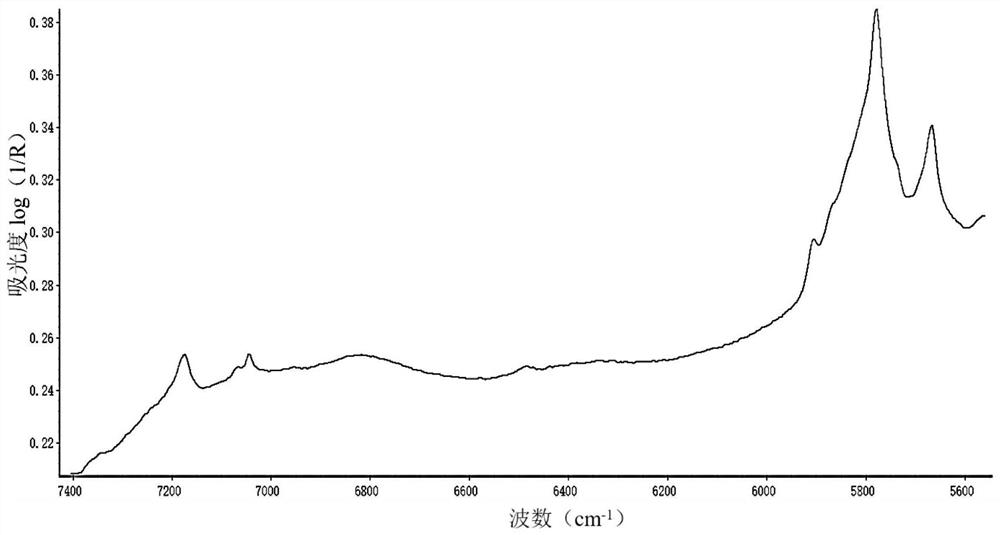

[0043] The collection of near-infrared spectra of the mixture during the mixing process can be controlled by the Result-Operation software. After opening the software, start to collect the background spectrum, and...

Embodiment 2

[0047] The detection method of embodiment 2 hydroxychloroquine sulfate particles mixing uniformity

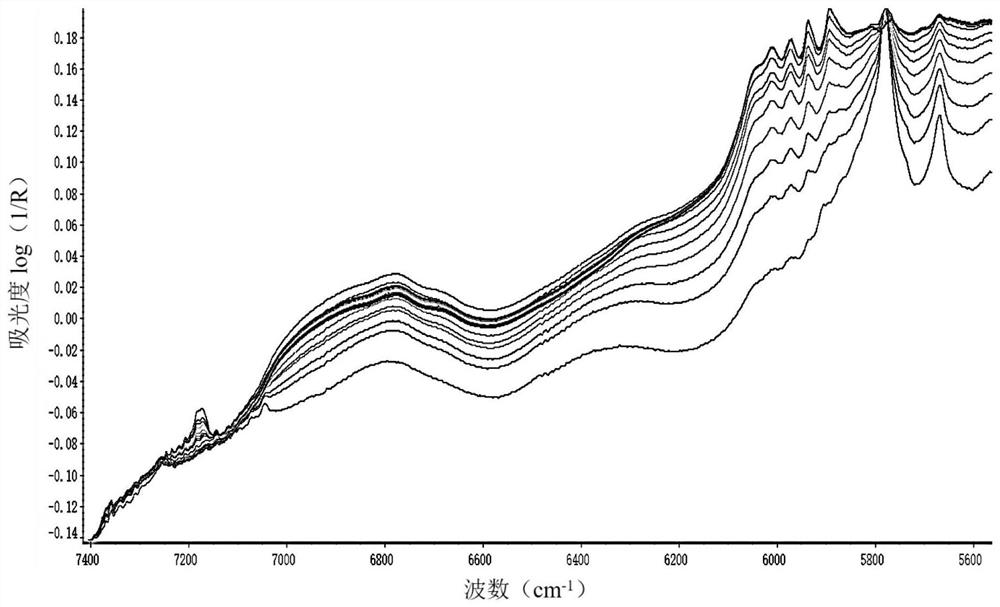

[0048] The compound batch among the embodiment 2 is PAT190806-5, and others are all the same as embodiment 1. Among them, the wavelength range is 5862-6059cm -1 The SD value line graph of the characteristic peak area is as follows Figure 5 shown.

[0049] At the 9th data point, the SD value was below 0.02, and it was determined that the hydroxychloroquine sulfate particles had been mixed evenly when mixing for 84s.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com