Lifting hole cover plate of electric turnover structure

A technology of hanging object hole cover plate and flip structure, which is applied in the direction of power control mechanism, trap door, building components, etc., and can solve the problems of insufficient lifting height of lifting equipment, large hole size of hanging objects, and inability to lift out hanging parts, etc. , to achieve the effect of occupying equipment space, low manufacturing cost, and less assembly man-hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The technical solutions in the embodiments of the present invention will be clearly and completely described below in conjunction with the accompanying drawings.

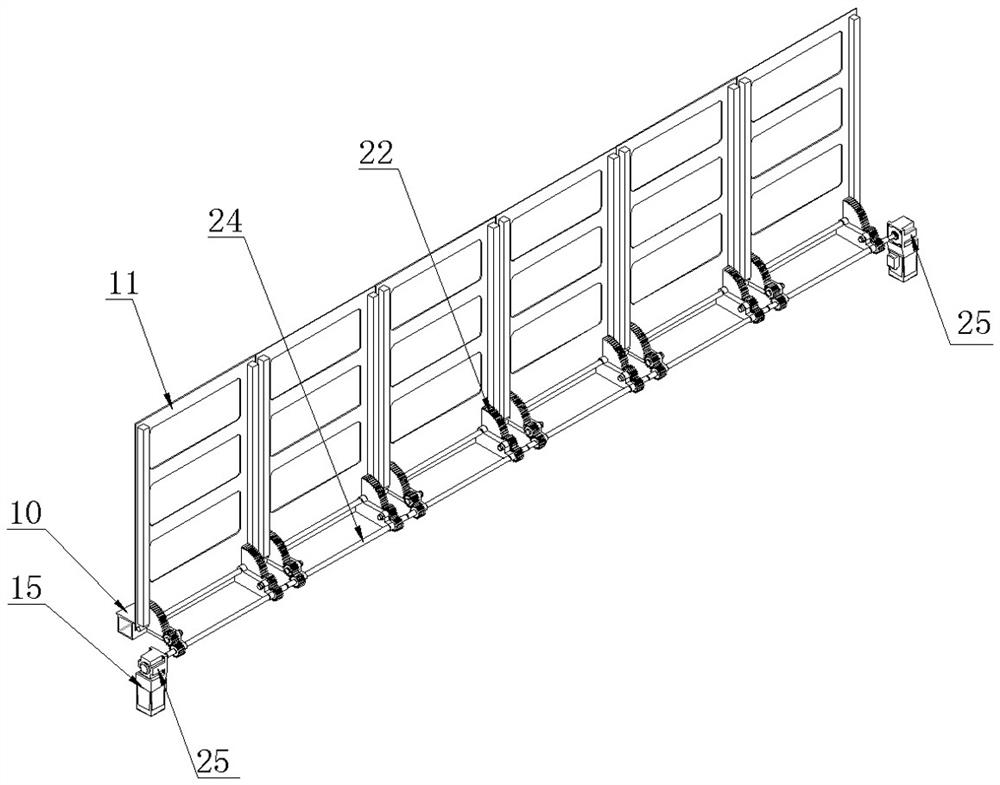

[0028] A hanging object hole cover plate with an electric flip structure, comprising an outer frame 10 arranged on the circumference of a rectangular hanging object hole matching the shape of the hanging object hole, the outer frame 10 includes two short sides opposite to each other and two opposite sides. The two long sides are arranged; the two short sides are respectively provided with the same structure of the openable guardrail 11; the two said long sides are respectively provided with the same structure of the movable and reversible door panel 12; the said guardrail One end of 11 is hinged with the support 13 arranged on the side wall of the short side; along the hinge of the guardrail 11 and the support 13 along the length direction of the guardrail 11, some opening and closing drive devices 20 for driv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com