Antibacterial coating with ph response function, functional material with antibacterial coating and preparation method thereof

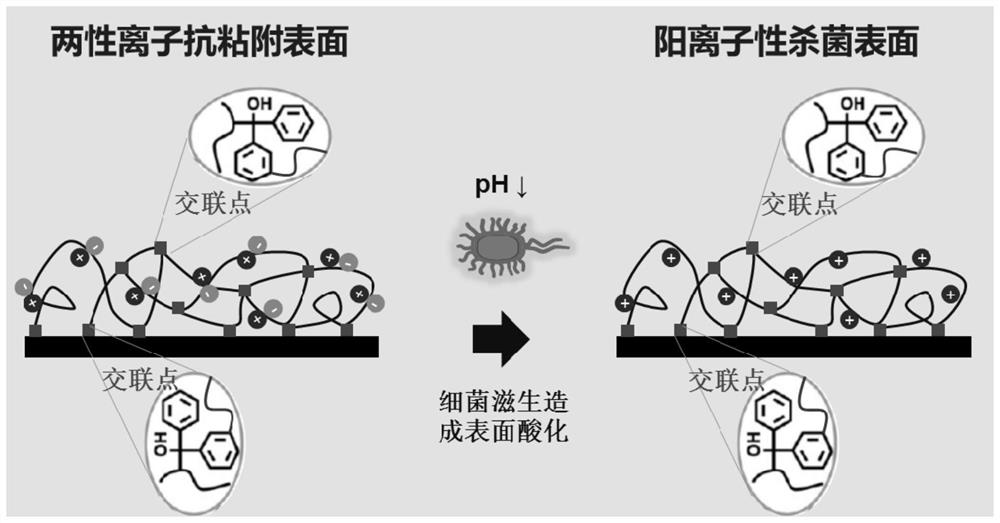

A technology of antibacterial coating and functional material, which is applied in the field of functional material of antibacterial coating and its preparation, can solve the problems of reducing bactericidal effect, inflammation and immune response, and high biological toxicity, and achieve good biocompatibility, reduce cell Toxicity, effect of firm coating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0133] The present invention provides a method for preparing a functional material with an antibacterial coating according to any one of the above technical solutions, characterized in that it includes the following steps:

[0134] 1) The monomer with R structure, with R 1 After the monomer of the structure and the first solvent are reacted, the first polymer intermediate is obtained after precipitation;

[0135] 2) the first polymer intermediate obtained by the above steps, having R 2 Monomer halogenated alkyl of X structure, with R 3 After the X-structured alkyl halide reacts with the first solvent again, the second polymer intermediate is obtained after precipitation; wherein, X is selected from Cl, Br or I;

[0136] 3) after carrying out the deprotection reaction of the second polymer intermediate, trifluoroacetic acid and the second solvent obtained in the above steps, the third polymer intermediate is obtained;

[0137] 4) the third polymer intermediate, concrete R obta...

Embodiment 1

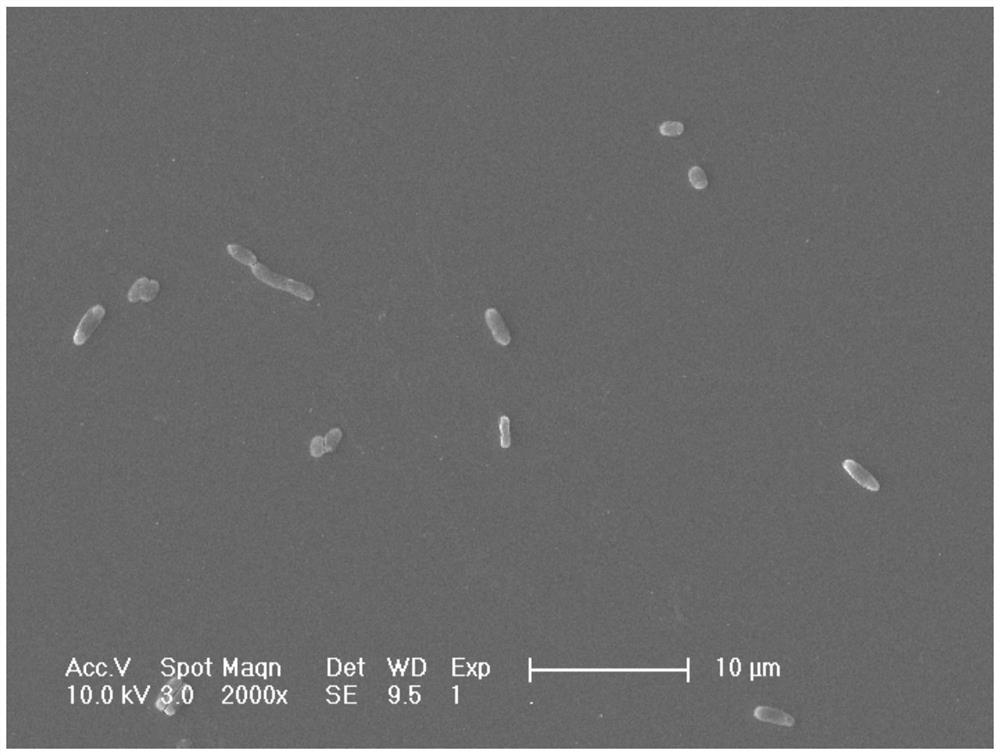

[0177] Preparation of Adaptive Medical Antimicrobial Catheter:

[0178] (1) Preparation of zwitterionic polymer:

[0179] Take 0.52g of ethylene glycol glycidyl ether and 0.64g of N-tert-butoxycarbonylethylenediamine in dimethyl sulfoxide as solvent at 60°C for 8h, then the ether precipitates, and after vacuum drying for 24h, take 500mg and 1mL of bromohexane and 100mg 3-bromobenzophenone was reacted in dimethyl sulfoxide solvent at 45°C for 24h. After the reaction, ether was precipitated and dried in vacuo. Finally, 500mg of the product was dissolved in 10mL of dichloromethane, and 3mL of trifluoroacetic acid was added and stirred at 25°C. 8h to remove the protecting group, and finally 500mg of the deprotected polymer was dissolved in 20mL of N,N-dimethylformamide solution, 100mg of maleic anhydride was added, magnetic stirring at 50°C for 24h, and dialyzed in a 3500Da dialysis bag for 24h , resulting in a zwitterionic polymer.

[0180] (2) Preparation of coating liquid:

...

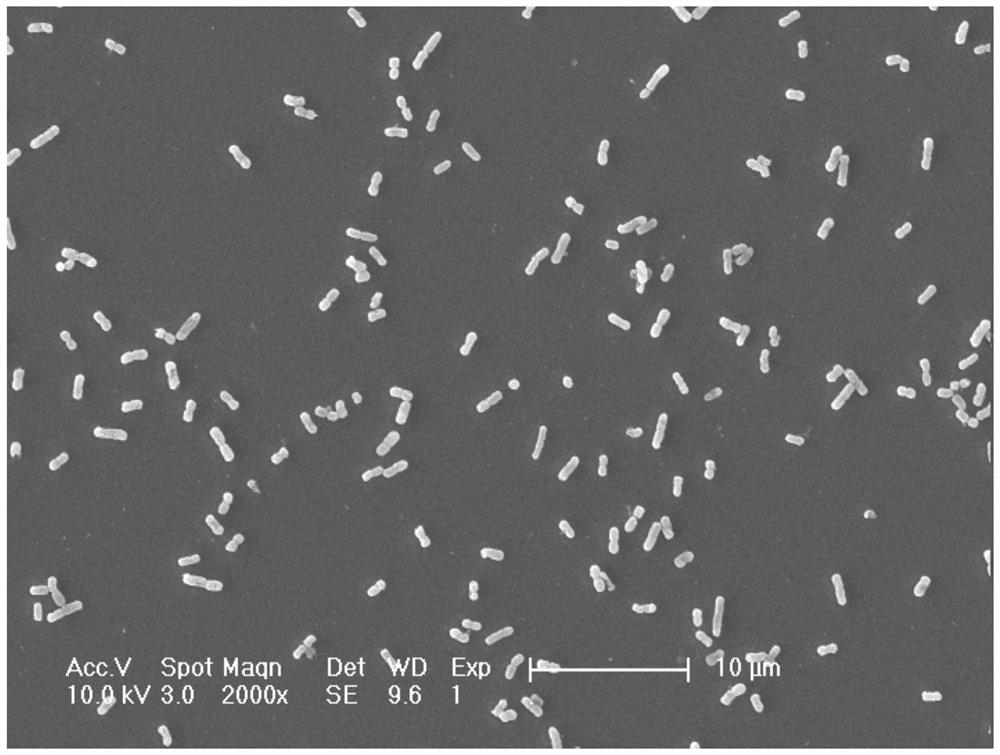

Embodiment 2

[0185] (1) Preparation of zwitterionic polymer:

[0186] Take 0.48g of diglycidyl ether and 0.71g of N-tert-butoxycarbonyl-1,3-propanediamine in N,N-dimethylacetamide at 80°C for 6h, then react with ether for 6h, vacuum dry for 24h and take 500mg of 1.2 mL of bromododecane and 85 mg of 4-bromobenzoyl benzene were reacted in N,N-dimethylacetamide at 50°C for 24 h. After the reaction, n-hexane was precipitated and dried in vacuo. Finally, 500 mg of the product was dissolved in 10 mL of dimethylacetamide. Chloromethane, add 2.2 mL of trifluoroacetic acid, and stir at room temperature for 12 h to remove the protective group. Finally, 500 mg of the deprotected polymer was dissolved in 20 mL of dimethyl sulfoxide solution, and 2,3-dimethylmaleate was added. Acid anhydride 115mg, magnetic stirring at 55°C for 24h, dialysis in a 3500Da dialysis bag for 24h, to obtain a zwitterionic polymer. .

[0187] (2) Preparation of coating liquid:

[0188] Take 1 g of the polymer obtained in s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com