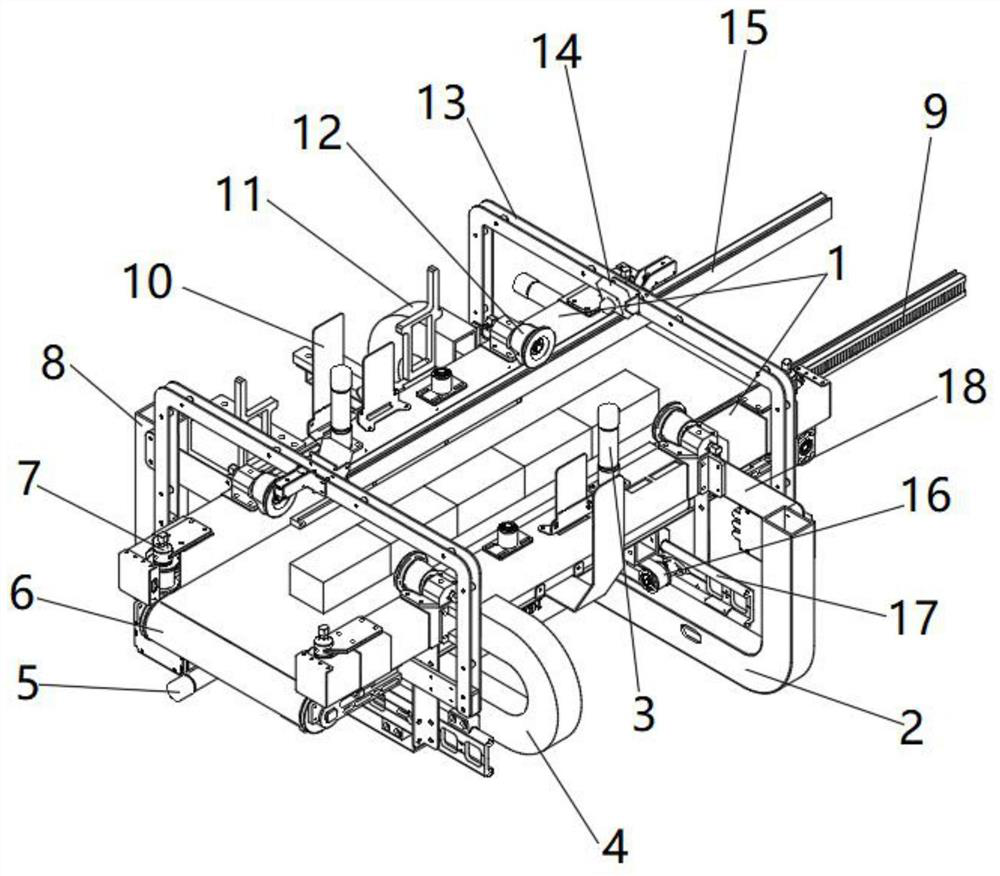

Clamping unit of automatic dispensing machine

A medicine dispenser, automatic technology, applied in conveyors, conveyor objects, packaging and other directions, can solve the problems of heavy platform weight, drug extrusion, short life and other problems, achieve flexible and free lifting movement, efficient two-way movement, quietness Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

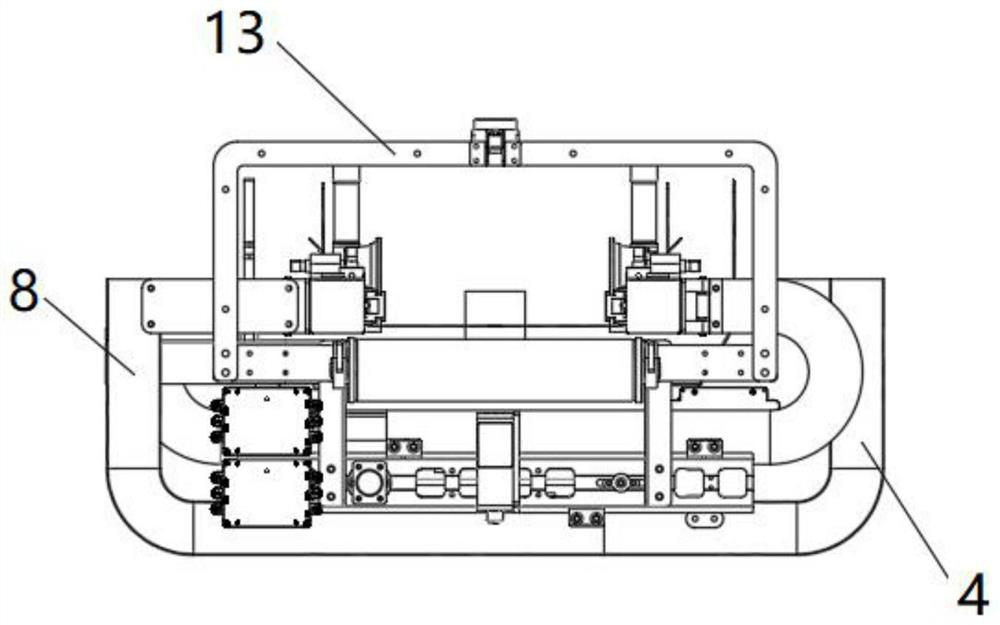

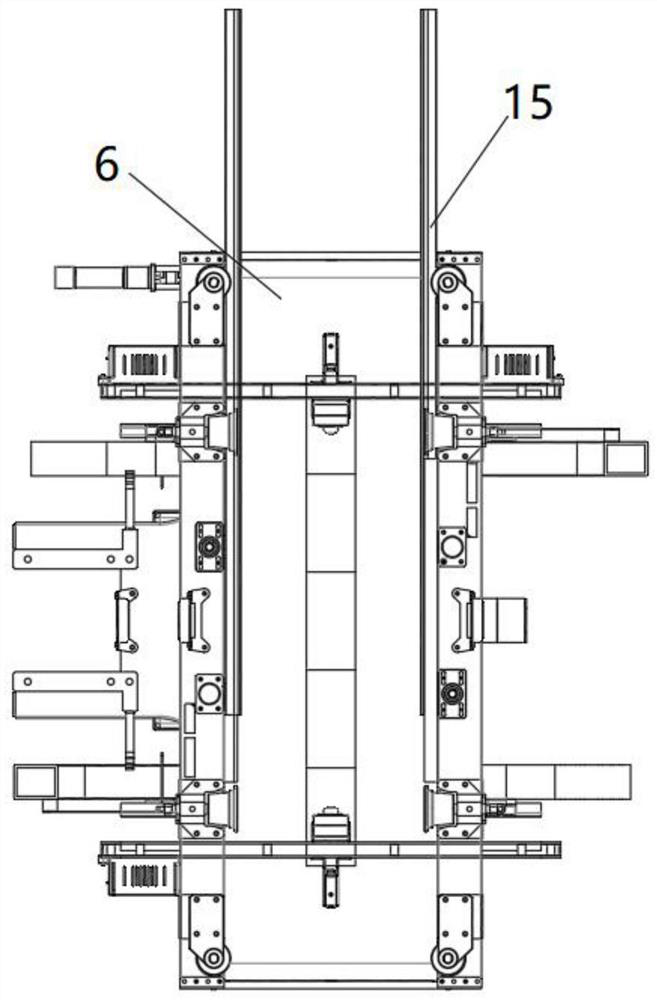

[0040] Embodiment 1, when the medicine is clamped, after the PLC controller receives the instruction, it drives the transmission motor 5 below to rotate, and the transmission motor 5 rotates to drive the transmission wheel to rotate, and the transmission wheel drives the synchronous belt to generate power, so that the synchronous belt drives the synchronous The pulley 16 moves, and the synchronous pulley 16 moves through the support to drive the opening and closing movable beam 1 to move, adjust the opening size of the opening and closing movable beam 1, and the PLC controller controls the micro DC motor 3 on the opening and closing movable beam 1 to work, and the micro The rotation of the DC motor 3 drives the gear to rotate, and the rotation of the gear drives the rack 9 on the two-way telescopic gripper 15 to move, and drives the two-way telescopic gripper 15 to stretch out. The moving beam 1 moves inward to clamp the medicine box, and the micro DC motor 3 drives the two-way...

Embodiment 2

[0042] Embodiment 2, two sets of transmission motors 5 are installed on the supports at both ends respectively. When the medicine is clamped, after the PLC controller receives the instruction, the PLC controller drives the transmission motors 5 at both ends respectively, so that the two ends open. The moving crossbeam 1 forms a certain angle (non-parallel motion), and the PLC controller controls the opening and closing of the moving crossbeam 1. The micro DC motor 3 is energized to work, and the rotation of the micro DC motor 3 drives the gear to rotate, and the gear rotates to drive the two-way telescopic gripper 15 The rack 9 on the top moves, driving the two-way telescopic gripper 15 to stretch out. After the bidirectional telescopic gripper 15 reaches the specified depth of the shelf, the drive motor drives the opening and closing moving beam 1 to move inward to clamp the medicine box, and the micro DC motor 3 drives The two-way telescopic jaw 15 retracts the original posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com