Flusher and assembly assembling system thereof

A technology of assembly assembly and washer, which is applied in the field of washer, can solve the problems of low production efficiency, high labor intensity of workers, low degree of automation, etc., and achieve the effect of convenient operation of adjustment and improvement of convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is further illustrated by the following examples.

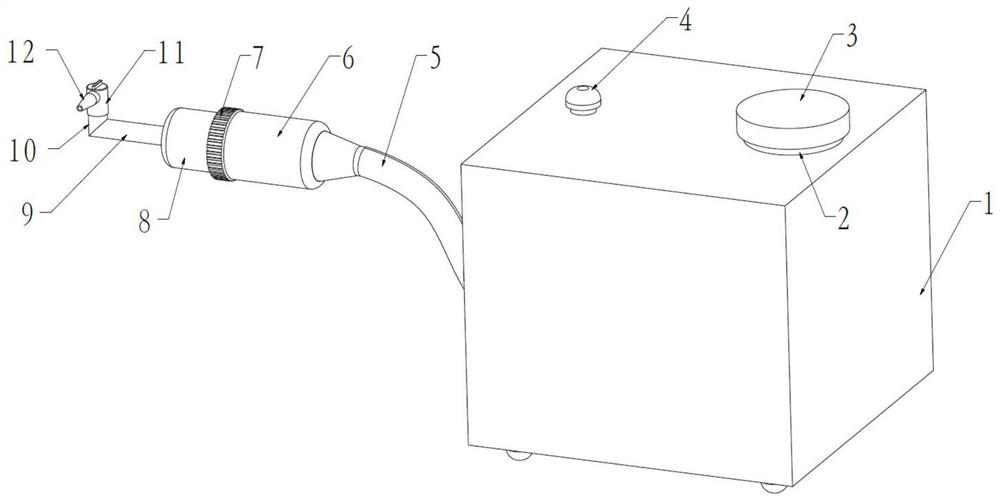

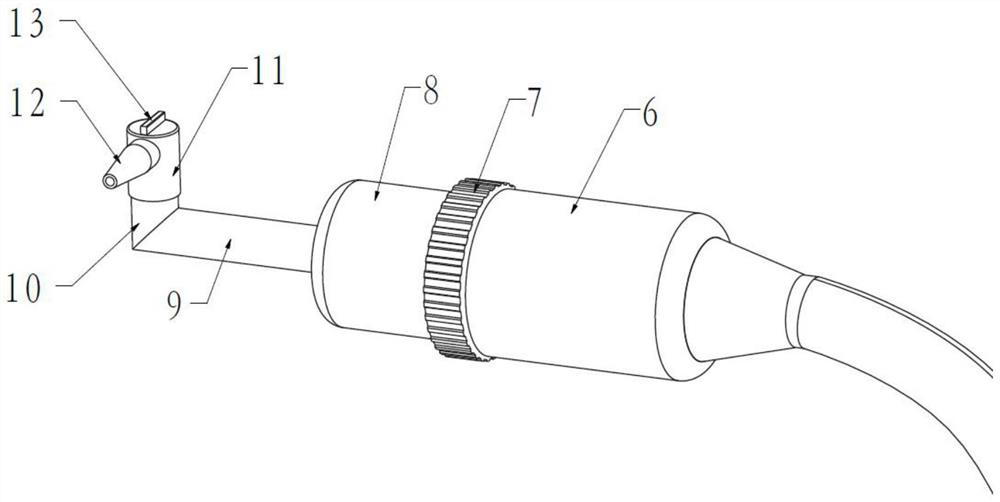

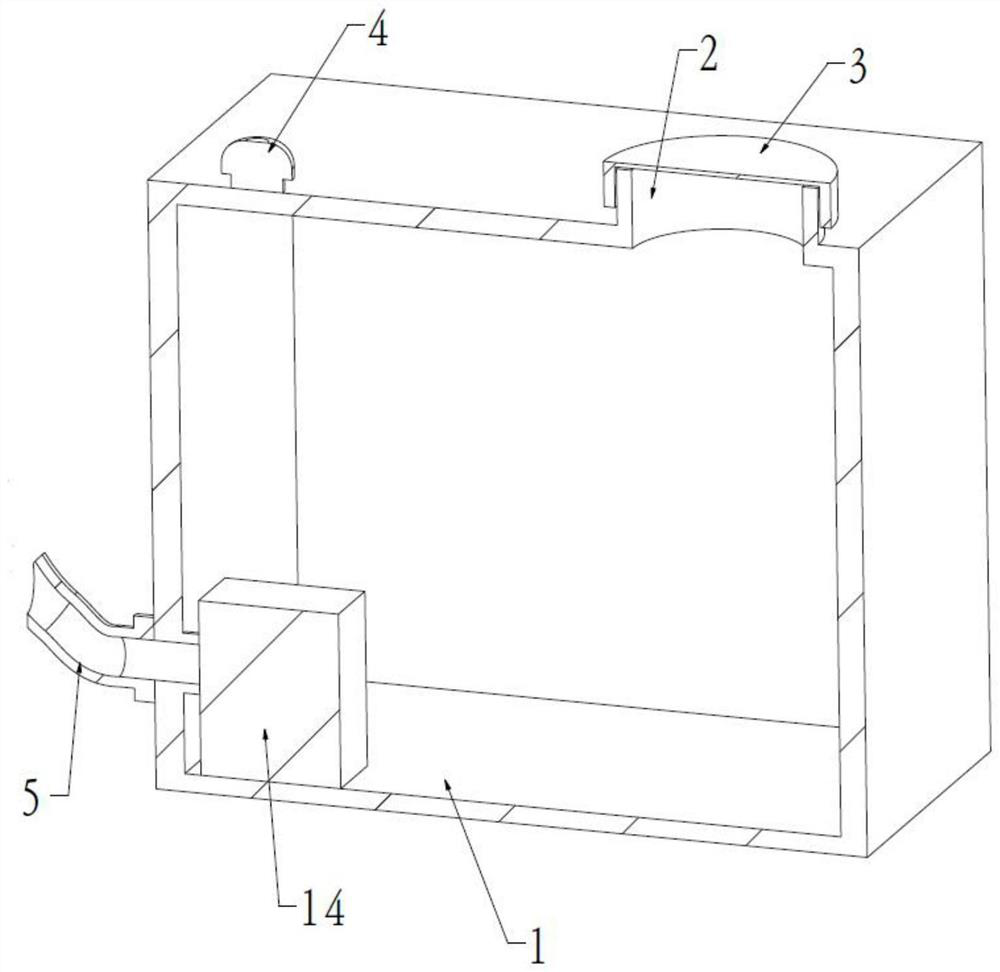

[0036] A washer and its assembly assembly system, comprising a liquid storage tank 1, a micro water pump 14 is arranged in the liquid storage tank 1, a liquid filling port 2 with a sealing cover 3 and a switch 4 are arranged on the top of the liquid storage tank 1, the said The micro water pump 14 is connected to the handle 6 through the hose 5, and the inside of the handle 6 is provided with a penetrating liquid outlet to communicate with the hose 5, and the other end of the handle 6 communicates with the adjustment member 8, and the inside of the adjustment member 8 There is also a penetrating liquid outlet hole, the other end of the adjustment member 8 is provided with a liquid outlet pipe 9, and the tail end of the liquid outlet pipe 9 is provided with a nozzle assembly, the nozzle assembly includes a steering piece 11, and a nozzle 12 is arranged on the steering piece 11.

[0037] preferred, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com