Welding process of automatic welding equipment for high-pressure container

A technology for automatic welding and high-pressure vessels, applied in welding equipment, arc welding equipment, welding accessories, etc., can solve the problems of low automation, low welding efficiency, and poor welding quality, and achieve high welding efficiency, high welding quality, and high welding quality. Seam metal crack resistance good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment provides a welding process for automatic welding equipment for high-pressure vessels by taking the welding of the head of the water chamber of the high-pressure heater and the annular seam of the tube sheet as an example.

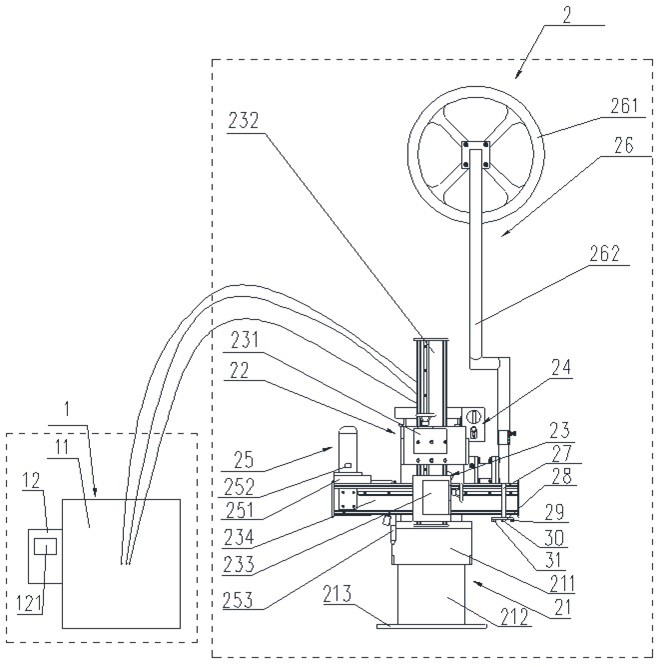

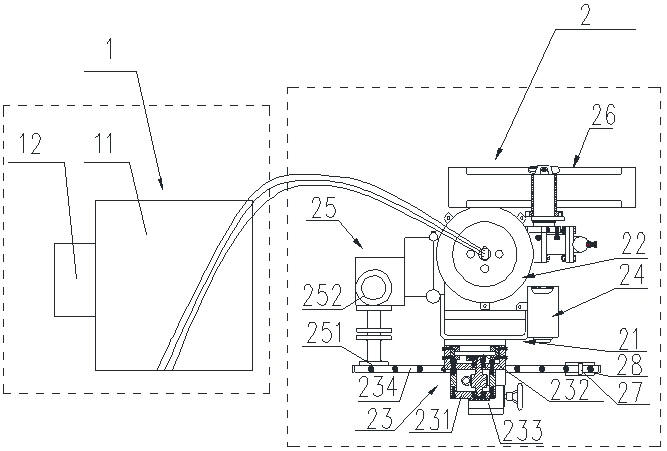

[0039] The process adopts an automatic welding equipment for high-pressure vessels, and the automatic welding equipment for high-pressure vessels includes a welding machine 1 and a special tooling 2 for welding.

[0040] The welding machine 1 includes a welding machine body 11 and a welding machine control system 12 , and a touch screen 121 is arranged on the welding machine control system 12 .

[0041] The welding special tooling 2 includes a machine base 21, a welding mechanism drive box 22 installed above the machine base 21, and a displacement mechanism 23 installed on one side of the welding mechanism drive box 22, which is fixed on the welding machine by screws. The switch controller 24 on the other side of the mechanism driving...

Embodiment 2

[0062] This embodiment provides a welding process for automatic welding equipment for high-pressure vessels by taking the welding of the manhole barrel section and the head of the high-pressure heater as an example.

[0063] This process adopts a kind of automatic welding equipment for high-pressure vessels, and the automatic welding equipment for high-pressure vessels is the same as that in Embodiment 1.

[0064] The process includes the following steps:

[0065] (1) Adjust the position of the workpiece to be tested so that the center of the workpiece to be tested is in a horizontal state, and at the same time clean the welding groove, place the workpiece clamping mechanism 213 at the lower end of the machine base 21 on the center of the workpiece to be welded, adjust The clamping size of the workpiece clamping mechanism 213 and clamps the workpiece to be measured, so that the workpiece to be measured and the workpiece clamping mechanism 213 remain relatively fixed and ready ...

Embodiment 3

[0073] This embodiment provides a welding process for automatic welding equipment for high-pressure vessels by taking the welding of the water supply pipe of the high-pressure heater and the head as an example.

[0074] This process adopts a kind of automatic welding equipment for high-pressure vessels, and the automatic welding equipment for high-pressure vessels is the same as that in Embodiment 1.

[0075] The process includes the following steps:

[0076] (1) Adjust the position of the workpiece to be tested so that the center of the workpiece to be tested is in a horizontal state, and at the same time clean the welding groove, place the workpiece clamping mechanism 213 at the lower end of the machine base 21 on the center of the workpiece to be welded, adjust The clamping size of the workpiece clamping mechanism 213 and clamps the workpiece to be measured, so that the workpiece to be measured and the workpiece clamping mechanism 213 remain relatively fixed and ready for u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com