Jacking process and jacking mechanism for additionally installing elevator in existing house

A jacking mechanism and elevator technology, applied to elevators, hoisting frames, hoisting devices, etc. in buildings, can solve problems such as elevators in residential areas that do not have transportation and lifting conditions, and reduce high-altitude hoisting and installation operations and operations Convenience, Adaptable Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

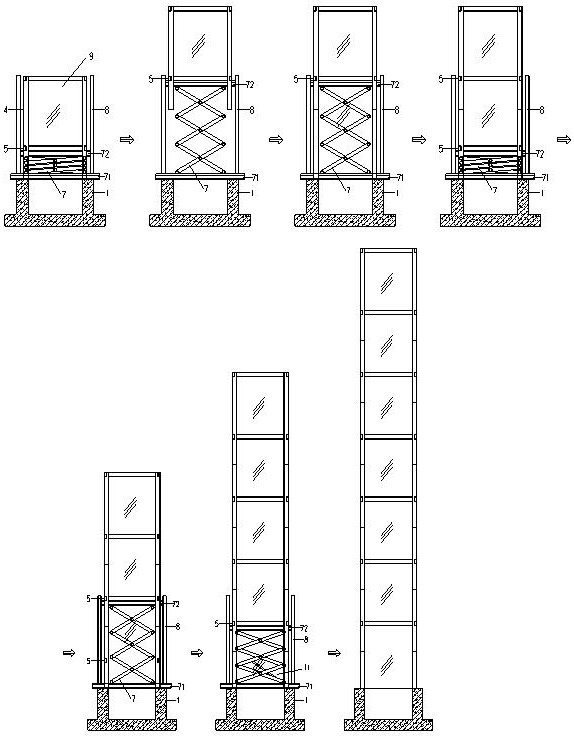

[0045] Below in conjunction with accompanying drawing, the existing house of the present invention is installed elevator jacking technique and jacking mechanism in detail.

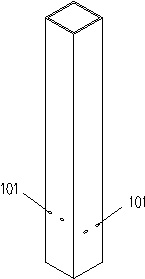

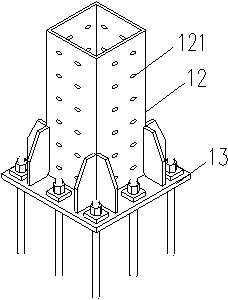

[0046] Such as figure 1 ,Such as figure 2 As shown, an elevator jacking mechanism is installed in an existing residence, including an elevator foundation pit 1, a scissor crane 7, a layer-by-layer spliced integral steel structure elevator shaft section, a steel column fixed column foot steel sleeve 12, and a jacking guide rail 8. The steel beam connecting piece 15 of the crane platform beam and the hoistway steel beam and the guide rail pulley connecting piece 16.

[0047] Such as figure 2 As shown, the elevator foundation pit 1 and its side wall 2 can be completed with cast-in-situ concrete structure or prefabricated concrete structure. 14. The thickness of the side wall 2 of the elevator foundation pit is greater than or equal to the width of the embedded part 13 of the column foot steel sleeve an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com