Energy-saving and environment-friendly aggregate centralized feeding system

An energy-saving and environmentally friendly aggregate technology, which is applied in solid separation, screens, grids, etc., can solve the problems of inability to extrude aggregates, poor dredging effect, and inability to squeeze dredging, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

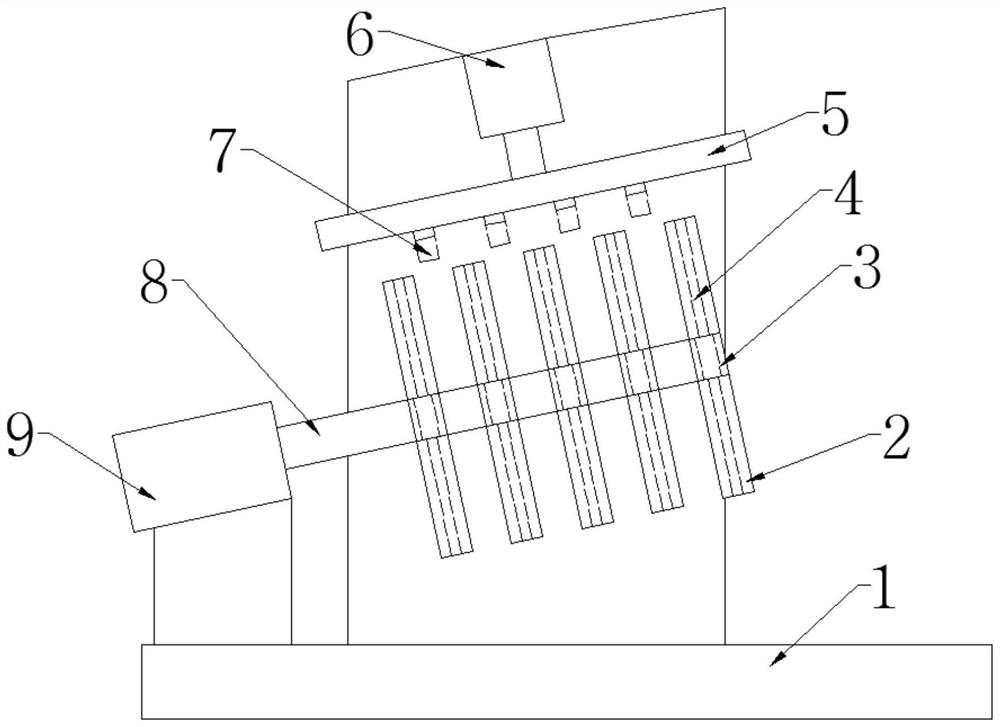

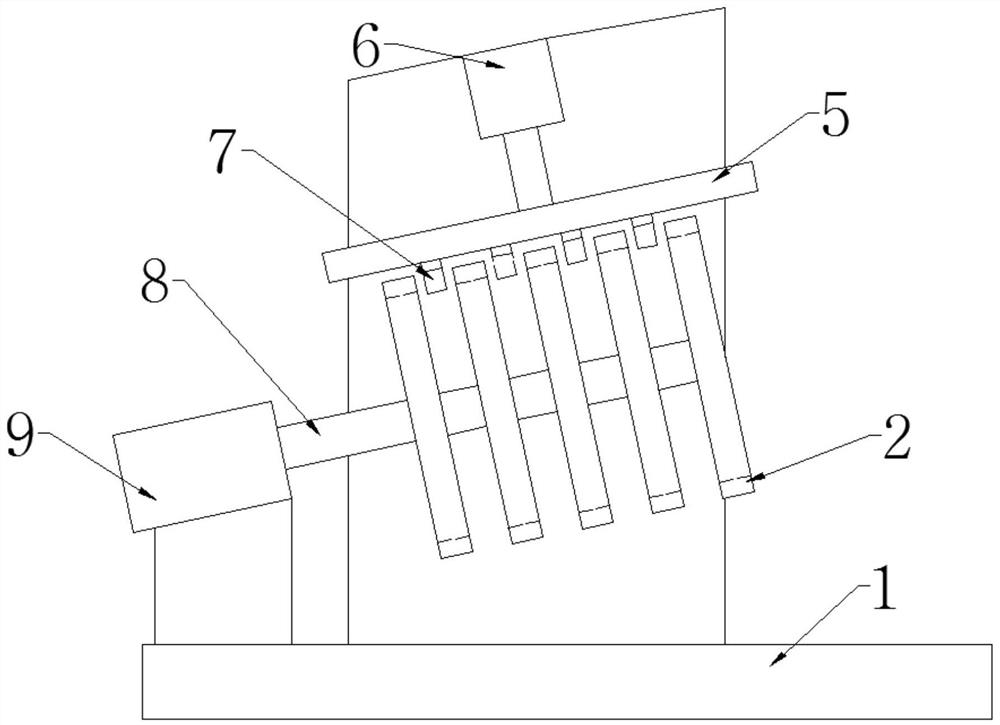

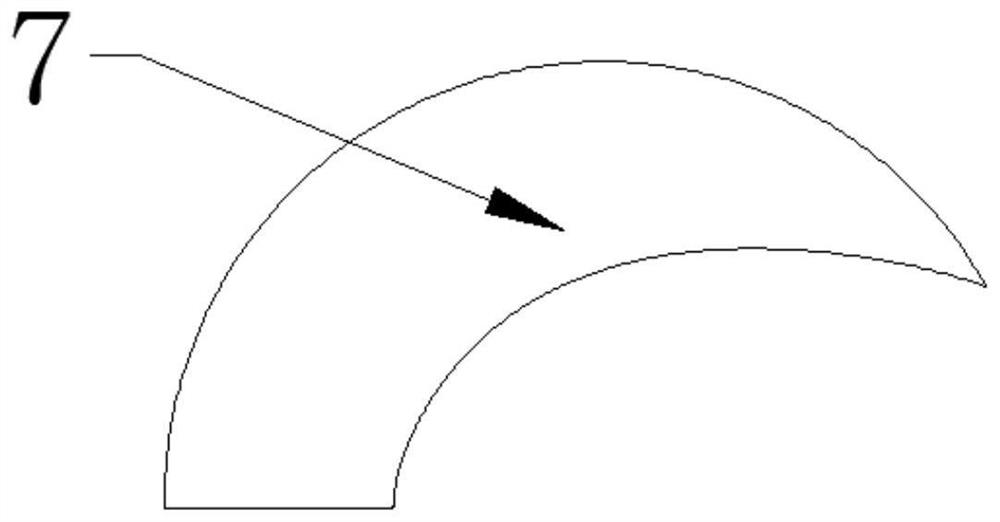

[0024] Embodiment 1: An energy-saving and environment-friendly centralized aggregate feeding system, including a frame 1 and a motor 9, the frame 1 is rotatably connected to a screening cylinder arranged obliquely, and the screening cylinder includes a drive shaft 8 and a plurality of screening rings 2, which are relatively Screening gaps are formed between adjacent screening rings 2, and the drive shaft 8 is fixed along its axis with connecting rings 3 matching the number of screening rings 2, and multiple screening rods are fixedly connected between each connecting ring 3 and the corresponding screening ring 2 4. The motor 9 and the drive shaft 8 are rotationally connected; the frame 1 is also fixedly equipped with a cylinder 6, and the movable end of the cylinder 6 is fixedly connected with an arc-shaped connecting plate 5, and the connecting plate 5 is fixedly connected and extends into the corresponding screening gap A plurality of extrusion blocks 7, the extrusion block 7...

Embodiment 2

[0027] Embodiment 2: The difference from Embodiment 1 is that the drive shaft 8 is provided with chutes 10 matching the number of screening rings 2 along its axis, and each connecting ring 3 is slidably connected with the corresponding chute 10, and the connecting ring 3 The sliding direction is parallel to the axis of the drive shaft 8 , and a spring 11 is fixedly connected between the opposite sides of each connecting ring 3 and the corresponding slide groove 10 .

[0028] In this scheme, the connecting ring 3 is limited by the limit pieces on both sides, so that when the aggregate is screened, the aggregate cannot push the connecting ring 3 to slide in the chute 10, and the connecting ring 3 fixes the screening ring 2 through the screening rod 4 , so that the screening gap between adjacent screening rings 2 will not change. During the extrusion process of the extrusion block 7, since the connecting ring 3 is movable, when the bulk aggregate with a larger blocking size is ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com