Laser mixed gas preparation device

A technology for mixing gases and preparation devices, which is applied in the direction of mixers, mixing methods, mixers with rotating stirring devices, etc., which can solve the problem of inability to ensure that multiple gases are mixed in the same proportion, multiple gases cannot be pre-mixed, and gas mixing is not uniform enough and other problems to achieve the effect of avoiding shaking, improving the stability of use, and facilitating installation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

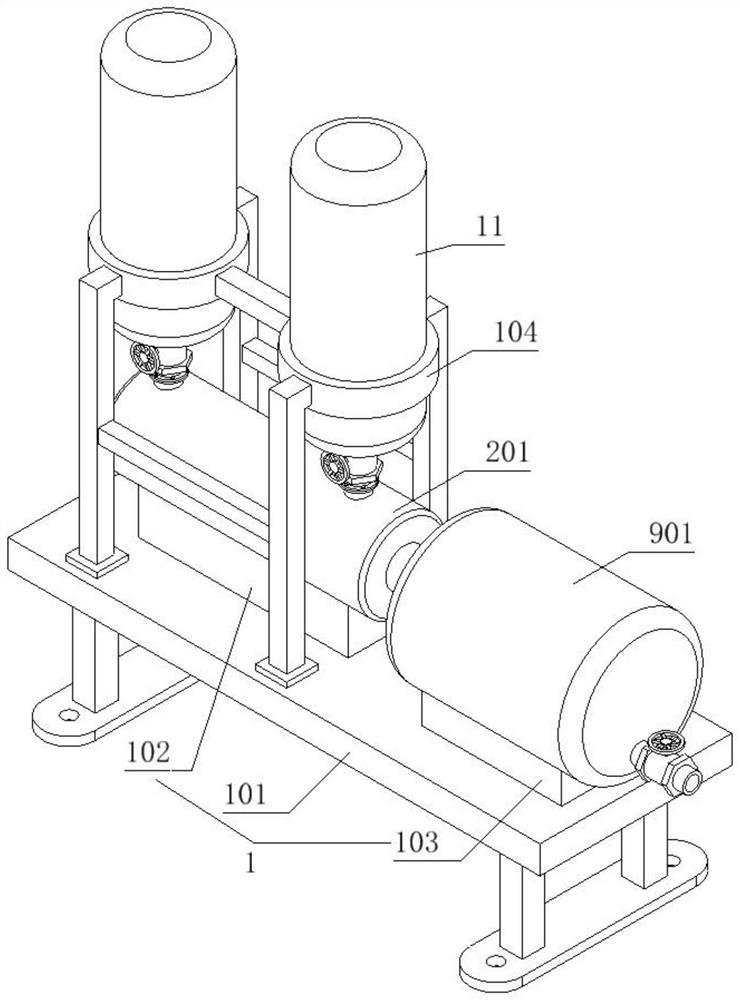

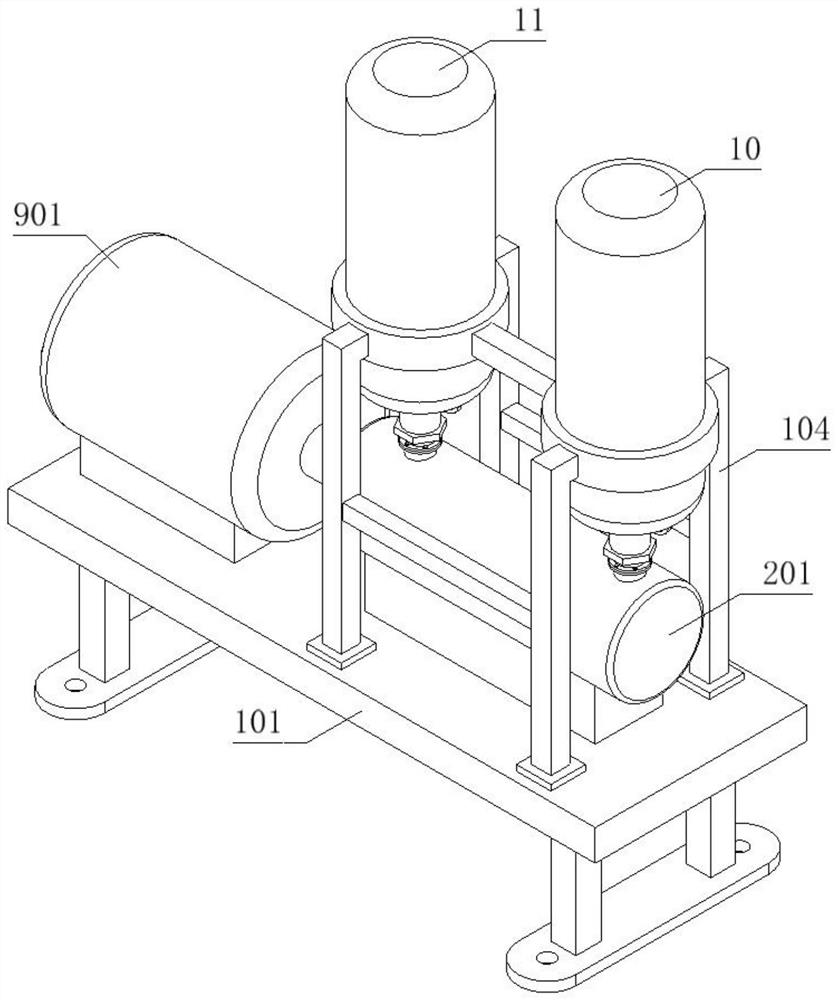

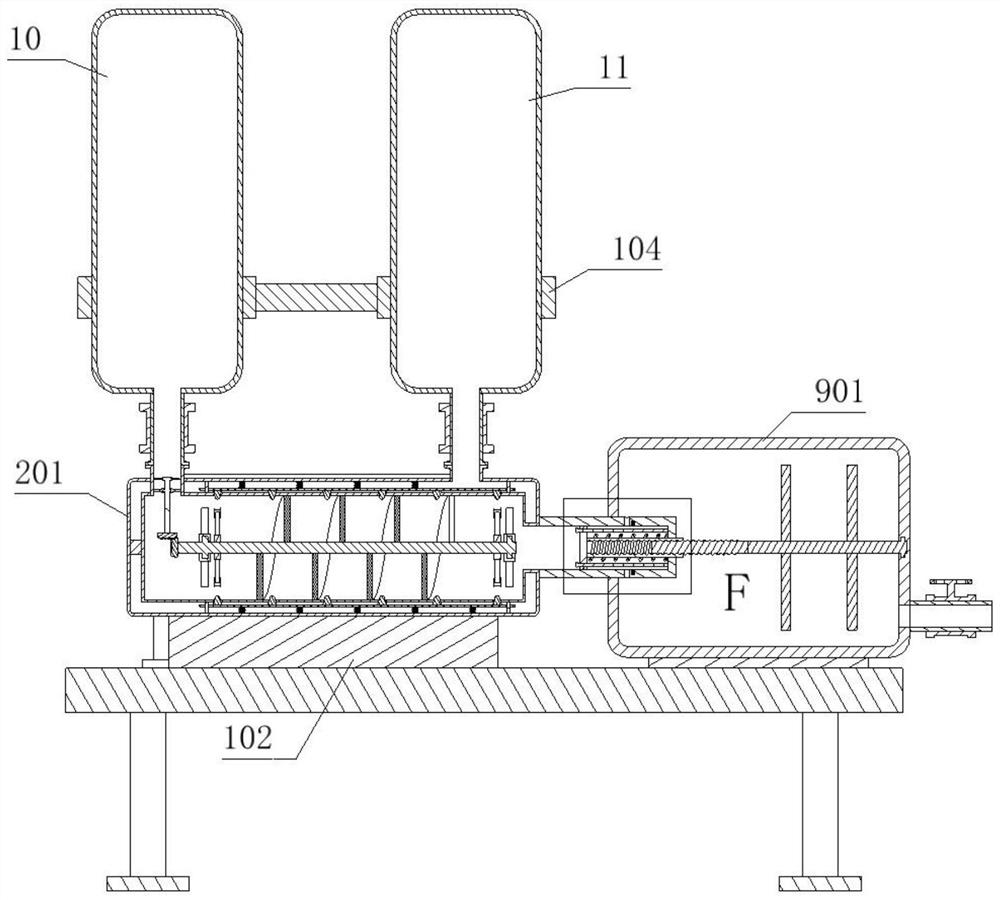

[0038] The preparation device of the laser mixed gas of the present embodiment, such as Figure 1-15 As shown, the device includes a mounting mechanism 1, a mixing device 2, a driving mechanism 3, a flow guiding device 4, an air intake mechanism 5, a sealing device 6, a connecting device 7, a fixing device 8 and a collecting device 9. The top of the mounting mechanism 1 Mixing device 2 is installed, and the top of described mixing device 2 is equipped with gas storage tank one 10 and gas storage tank two 11, and the inside of described mixing device 2 is equipped with deflector 4 and driving mechanism 3, and described deflector Two groups of air intake mechanisms 5 are installed symmetrically on 4, the mixing device 2 is connected to one end of the connecting device 7, and the collecting device 9 is connected to the other end, and multiple sets of sealing devices 6 are installed in the mixing device 2 , the fixing device 8 is installed in the connecting device 7 .

[0039] Su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com