High-precision ultrasonic metering channel

An ultrasonic, high-precision technology, used in measuring devices, measuring flow/mass flow, liquid/fluid solids measurement, etc., can solve the problem of high cost of commercial ultrasonic gas meters, achieve high stability, high accuracy, and reduce damage. the effect of the probability of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

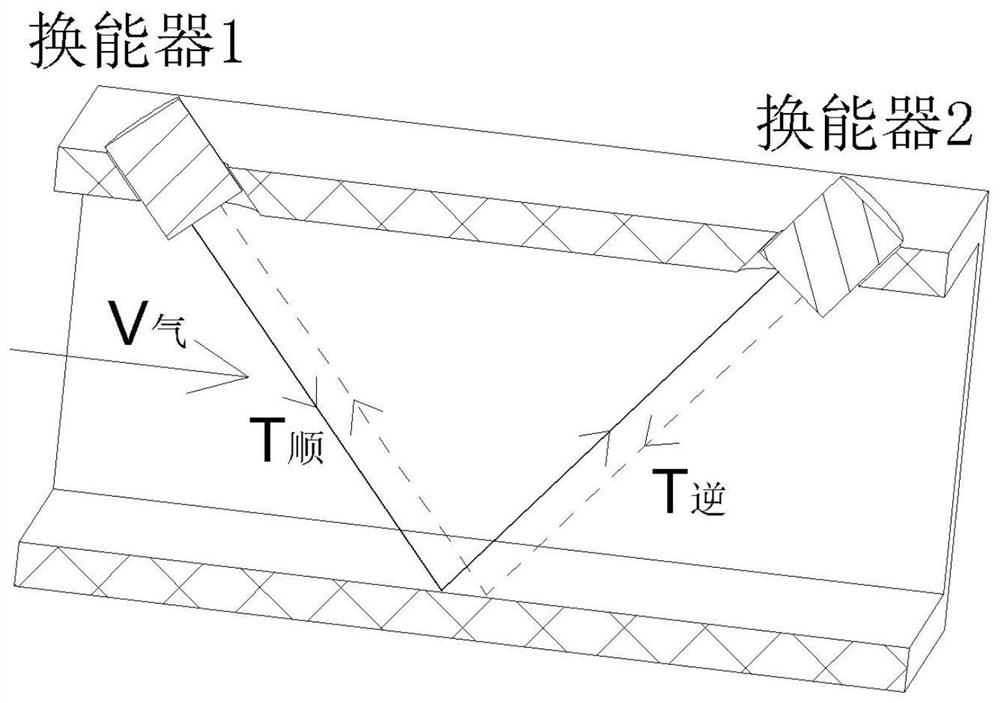

[0028] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

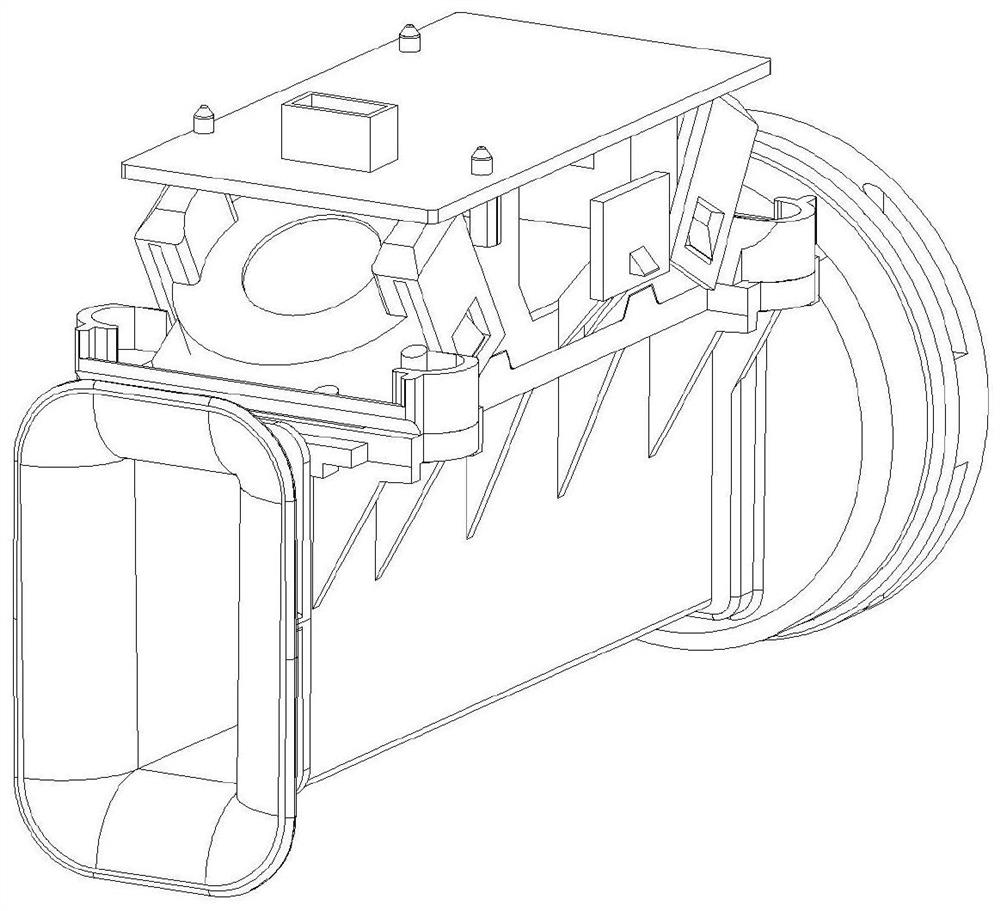

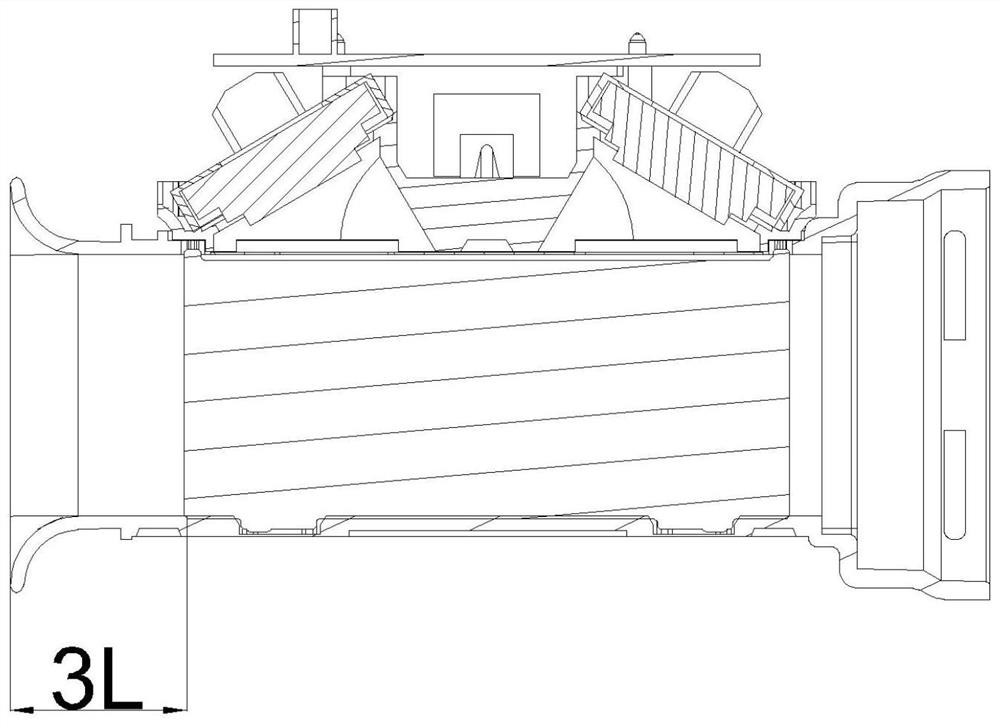

[0029] Such as Figure 6 , Figure 7 As shown, a high-precision ultrasonic metering channel includes a metering channel housing 7f, a partition sheet 7e, a blocking plate 7d, a channel bracket 7c, a metering module 7b and a channel cover 7a.

[0030] The separation sheet 7e is arranged in the metering channel housing 7f, and the stopper 7d is arranged at the opening above the metering channel housing 7f; the channel cover 7a is connected to the metering channel housing 7f, and the channel bracket 7c and the metering module 7b are arranged between the channel cover 7a and the metering channel. In the cavity formed by the channel housing 7f. The channel bracket 7c is an axisymmetric structure, connected to the metering channel housing 7f, corresponding to the position of the blocking plate 7d; there are two metering modules 7b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com