A pressure relief arrangement

A technology for releasing device and pressure, applied in valve device, substation/distribution device casing, cooling/ventilation of substation/switchgear, etc., can solve the problem of increasing the explosive rupture of casing, release pressure in a fast and effective way, and pressure release path The area is not large enough, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

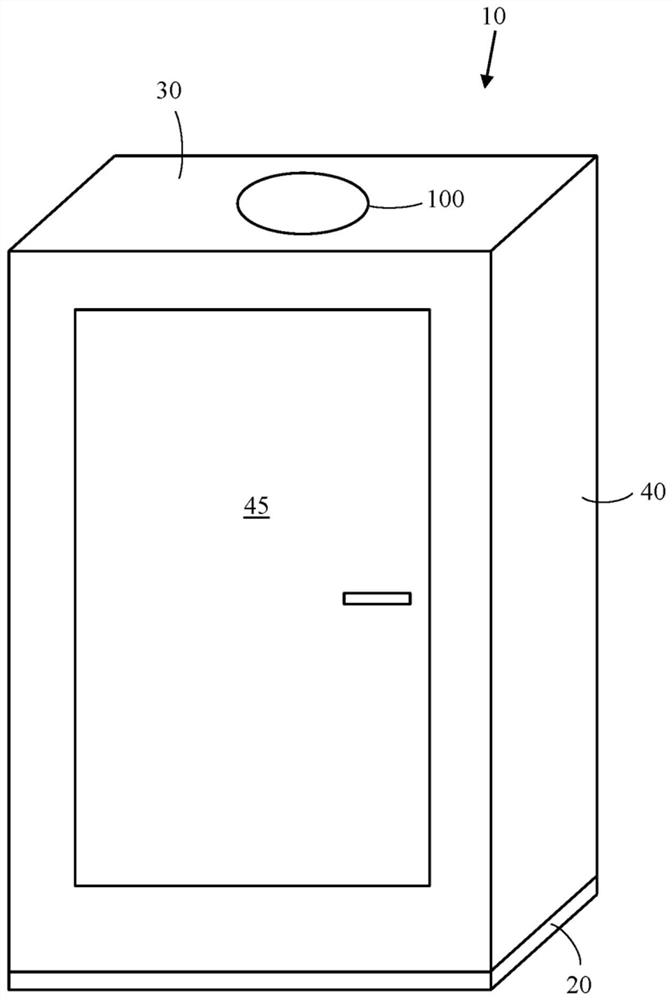

[0028] figure 1 Shown is an electrical cabinet with a pressure relief device.

[0029] The electrical cabinet 10 includes a bottom 20 , a top 30 and a side wall 40 extending between the bottom 20 and the top 30 of the electrical cabinet 10 . The front wall of the electrical cabinet 10 may include a door 45 . A pressure relief device based on a pressure relief hatch 100 may be positioned on the top 30 of the electrical cabinet 10 . However, the pressure relief hatch 100 may be positioned on any wall 40 of the electrical cabinet 10 . Wall 40 may be an exterior side wall of electrical cabinet 10 or be on an interior side wall of electrical cabinet 10 . The electrical cabinet 10 may include electrical equipment such as bus bars, electrical drives for electric motors, and the like.

[0030] The pressure relief hatch 100 may be positioned to connect with openings in the walls 30 , 40 of the electrical cabinet 10 .

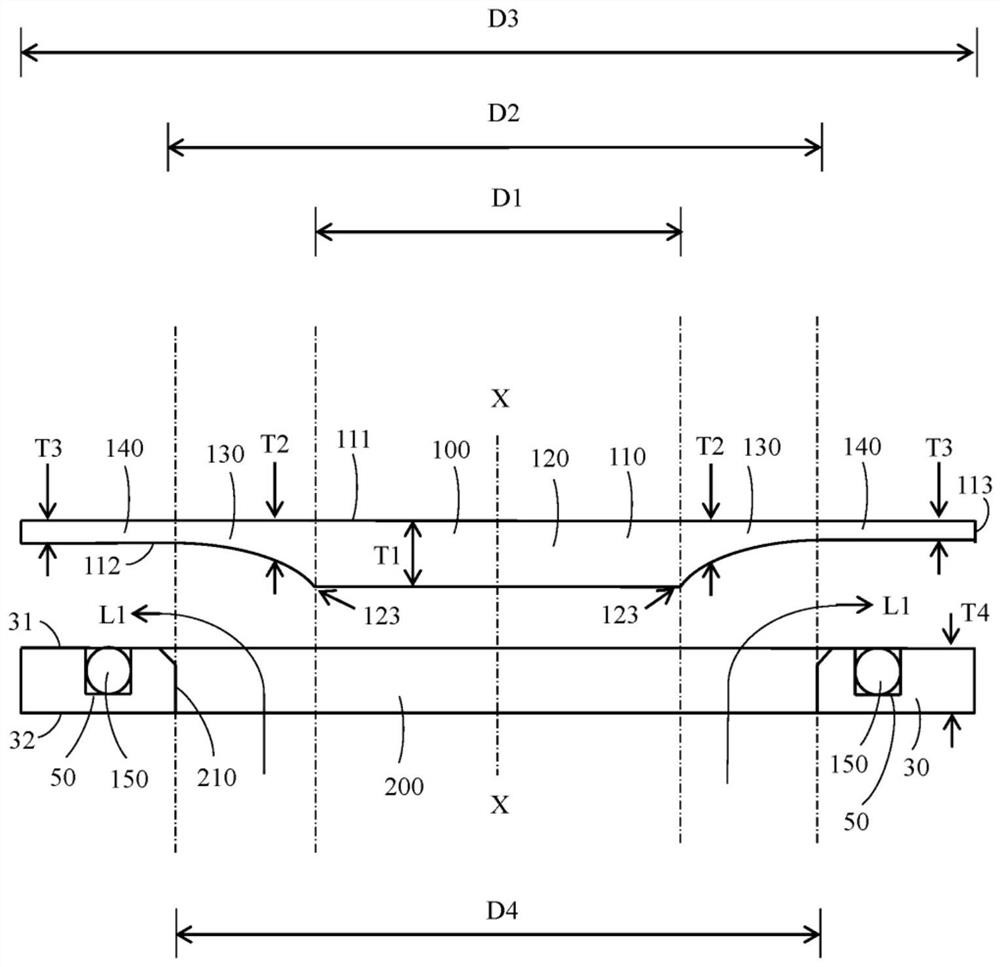

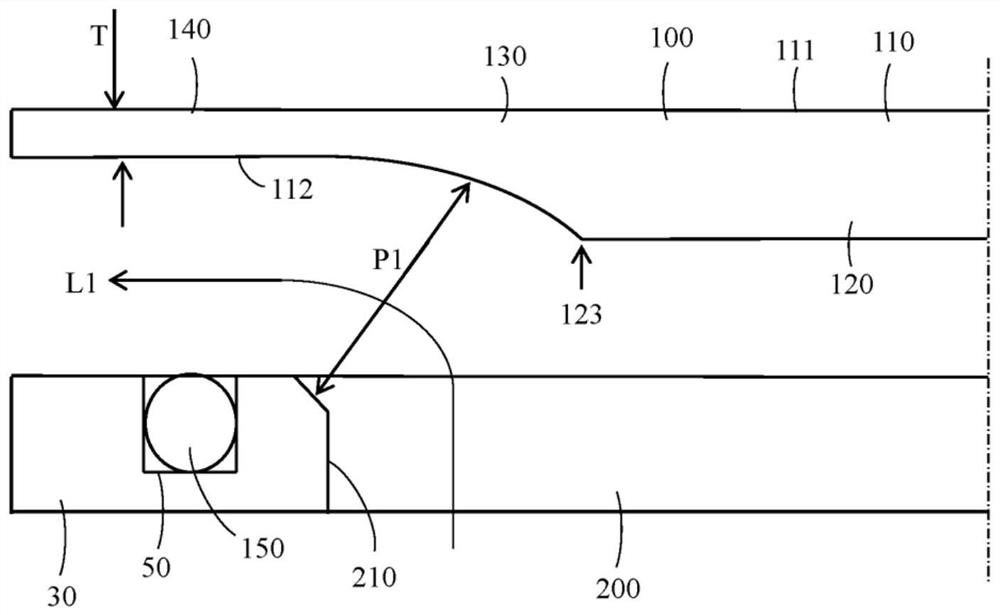

[0031] figure 2 A pressure relief device according to the in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com