Dry-type trolley differential pressure detection alarm device, method and system

A technology of alarm device and trolley, which is applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of affecting the collection effect of waste paint treatment, low observation accuracy, cumbersome and complicated operation process, etc., and achieve simple connection work, Improve efficiency and facilitate operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

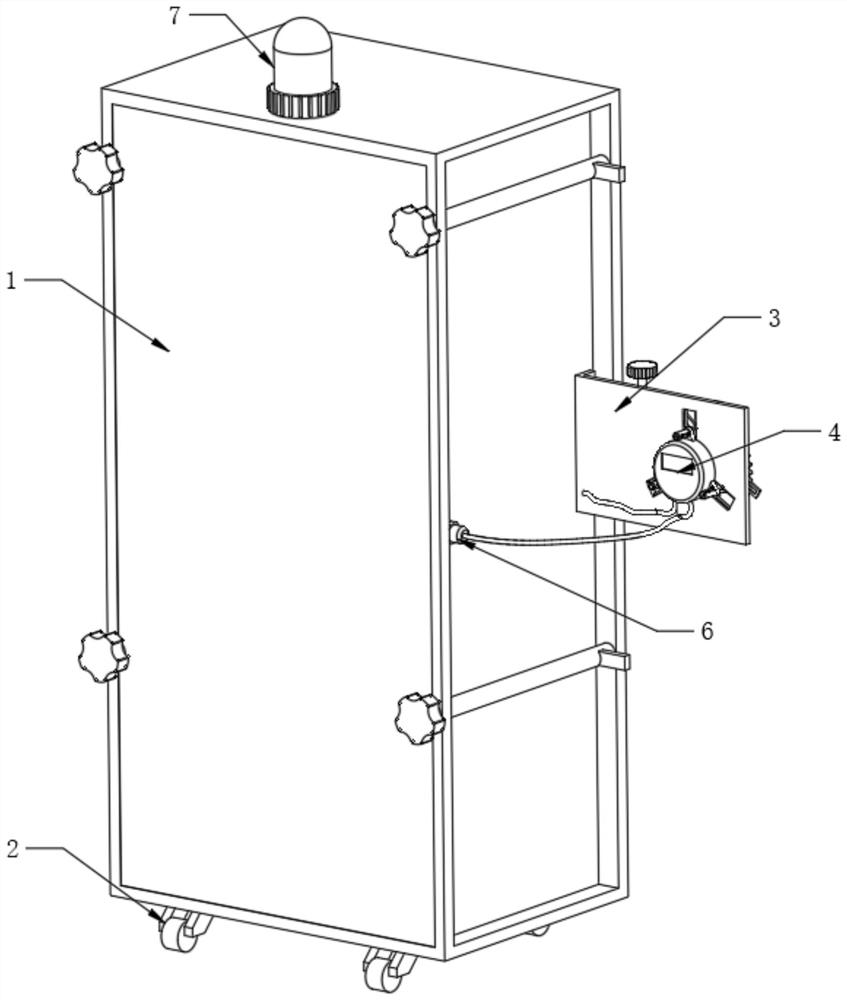

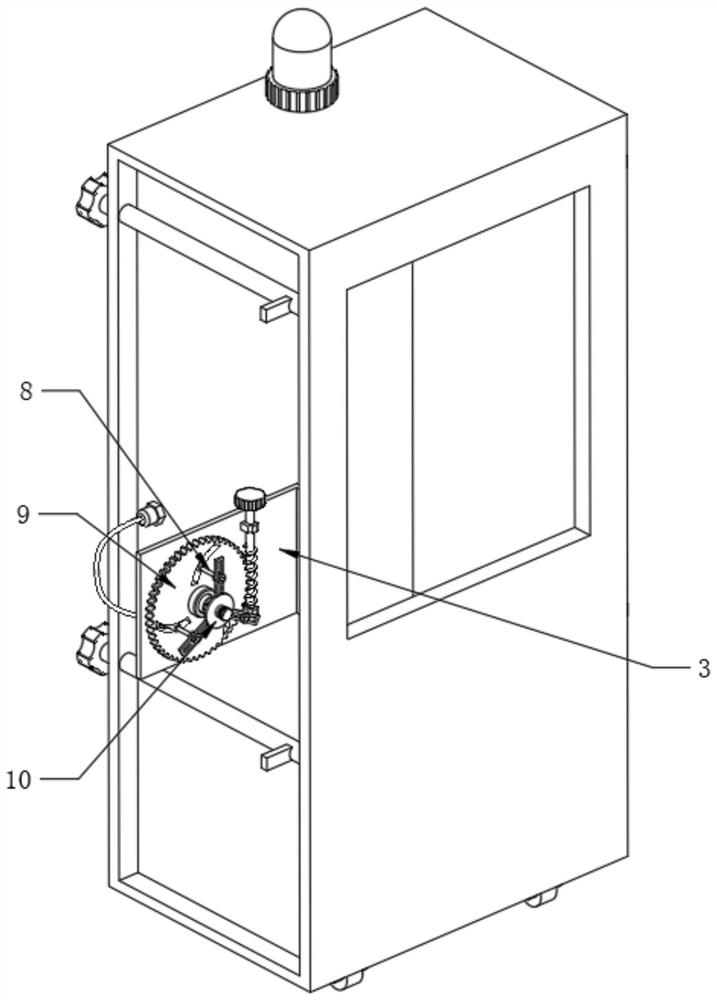

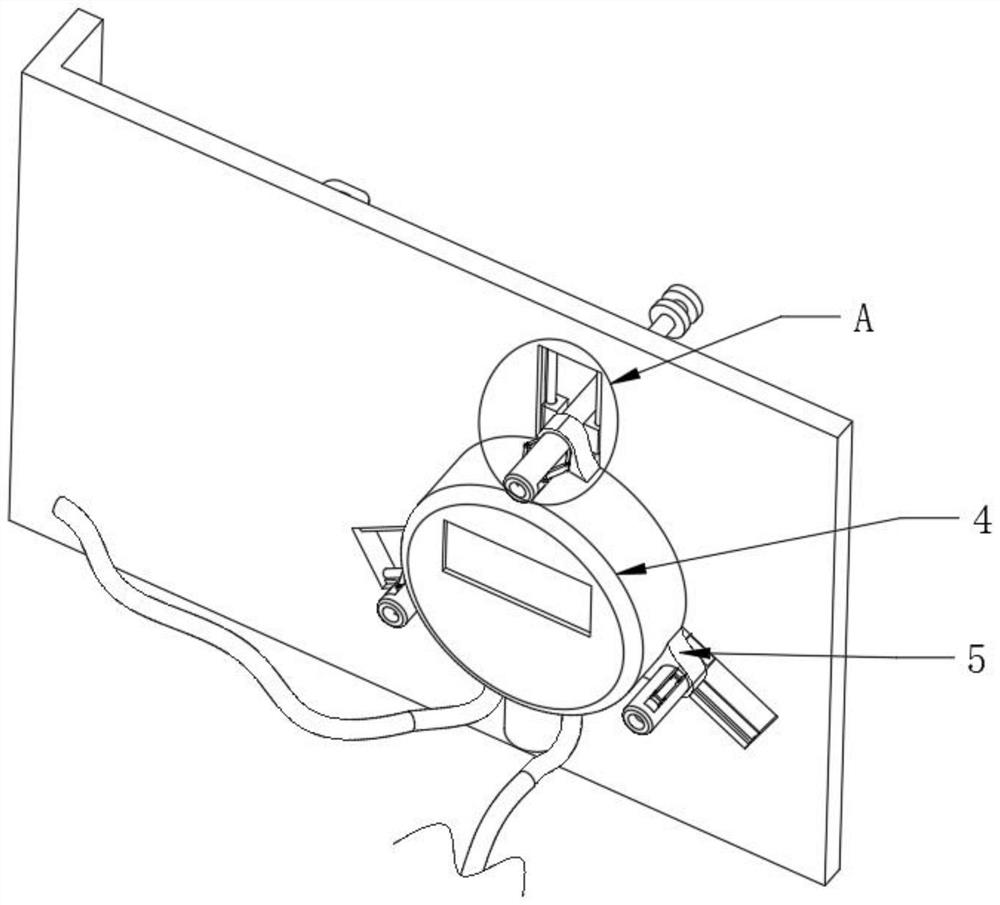

[0040] In the specific implementation process, such as figure 1 , figure 2 and image 3 As shown, a dry-type trolley differential pressure detection and alarm device includes a dry-type trolley main body 1 and self-locking universal wheels 2, and the bottom of the dry-type trolley main body 1 is equidistantly fixed with self-locking universal wheels 2. One side of the main body 1 of the dry-type trolley is fixed with an installation substrate 3, and one side of the installation substrate 3 is clamped with a transmitter 4, and the side of the transmitter 4 close to the installation substrate 3 is equidistantly fixed with installation ear blocks 5, and there are three mounting lugs 5, a differential pressure sensor 6 is fixed on the side of the dry trolley main body 1 close to the installation substrate 3, and the detection end of the differential pres...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com