Quick upper die changing structure and related equipment and method

A fast and laminating technology for equipment, applied in the direction of mechanical equipment, connecting components, cold-pressed connections, etc., can solve the problems that the structure is difficult to meet the requirements, the upper mold and the lower mold cannot be fully fitted, and it is difficult to form a closed vacuum cavity, etc., to achieve Quick replacement, lower processing accuracy requirements, and the effect of meeting processing needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. Note that the aspects described below in conjunction with the drawings and specific embodiments are only exemplary, and should not be construed as limiting the protection scope of the present invention.

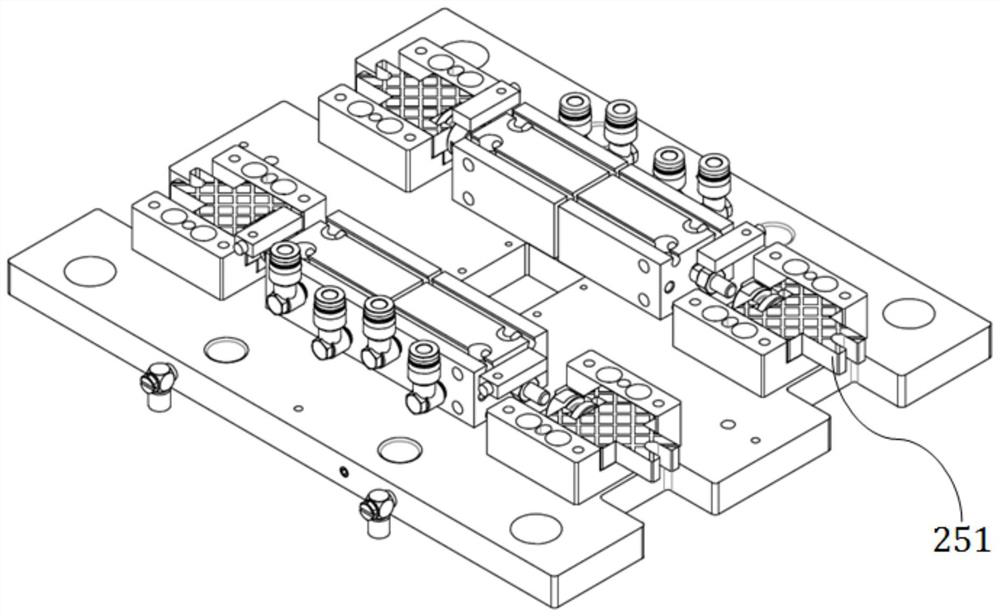

[0039] Such as figure 1 As shown, the embodiment of the present application provides a quick mold change structure for the upper mold, including a telescopic mechanism 2 connected to the lifting mechanism (such as figure 2 shown) and the locking mechanism 1 connected with the upper die 3 (such as image 3 shown), figure 2 Among them, only one lifting plate 4 of the lifting mechanism is shown for clarity. Wherein, the telescopic mechanism 2 includes a telescopic end 251 that can expand and contract in the horizontal direction; the locking mechanism 1 includes a force-reinforcing member 13 and a first surface 111a, when the telescopic end 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com