Rapid mold locking device

A clamping device and fast technology, applied in the direction of metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of inaccurate positioning and low efficiency of mold change, and achieve the effects of precise positioning, convenient operation and easy locking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

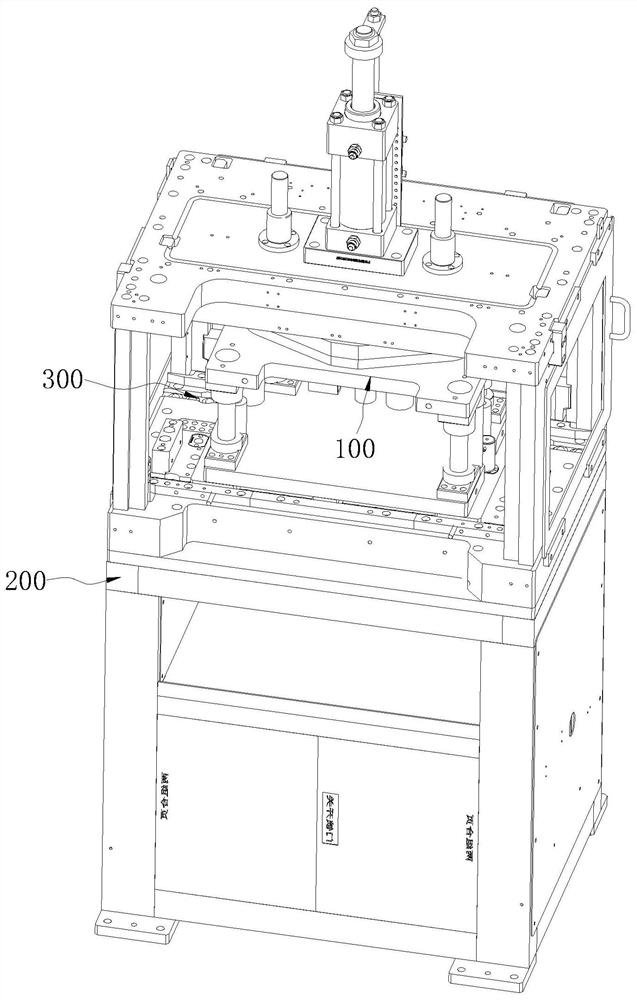

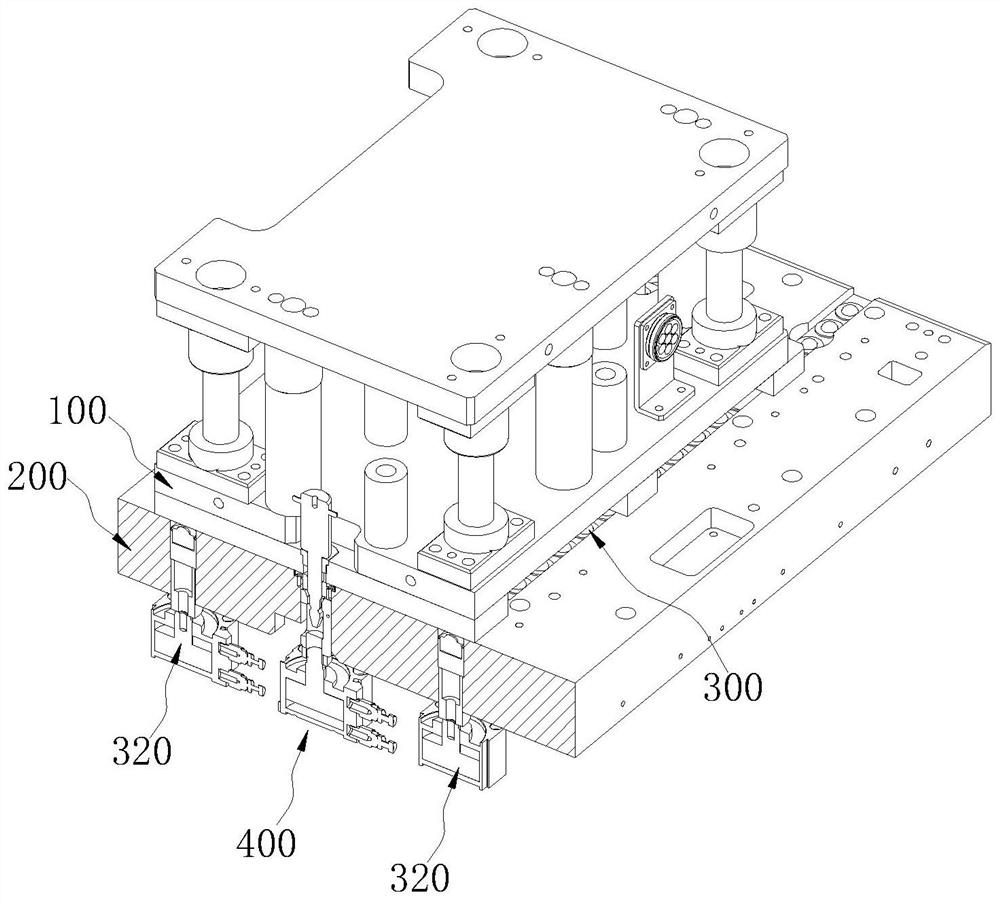

[0035] Please refer to Figure 1-Figure 6 , the present invention discloses a quick clamping device for installing a mold 100 on a machine tool 200, comprising:

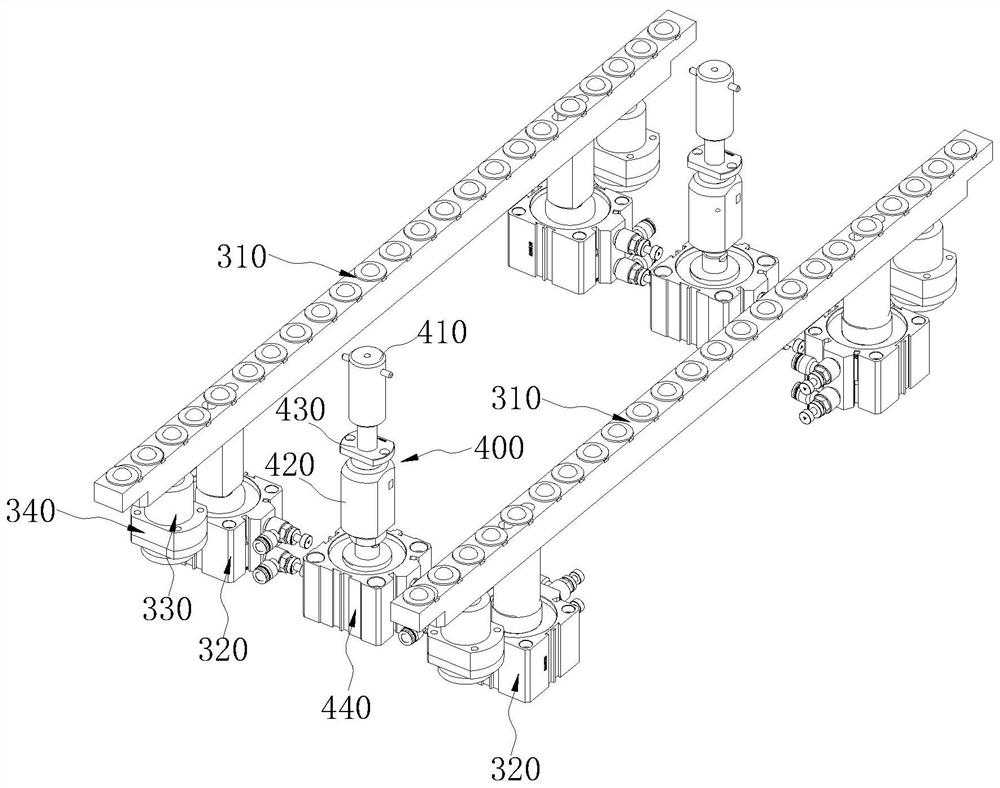

[0036] Lifting assembly 300, which is arranged on the machine tool 200, said lifting assembly 300 includes a mold lifter 310, and said mold lifter 310 can move along the height direction relative to said machine tool 200;

[0037] The mold locking assembly 400 is arranged on the machine tool 200, and the mold locking assembly 400 includes: a lock sleeve 420, which can move along the height direction relative to the machine tool 200; a lock pin 410, which has a second A connection section 411 and a second connection section 412, the first connection section 411 p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com