Equipment for detecting and automatically repairing cable insulating layer

A technology of cable insulation and equipment, which is applied in the field of equipment for cable insulation detection and automatic repair, which can solve the problems of inability to repair the damaged part of the insulation layer and inconvenience of comprehensive observation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

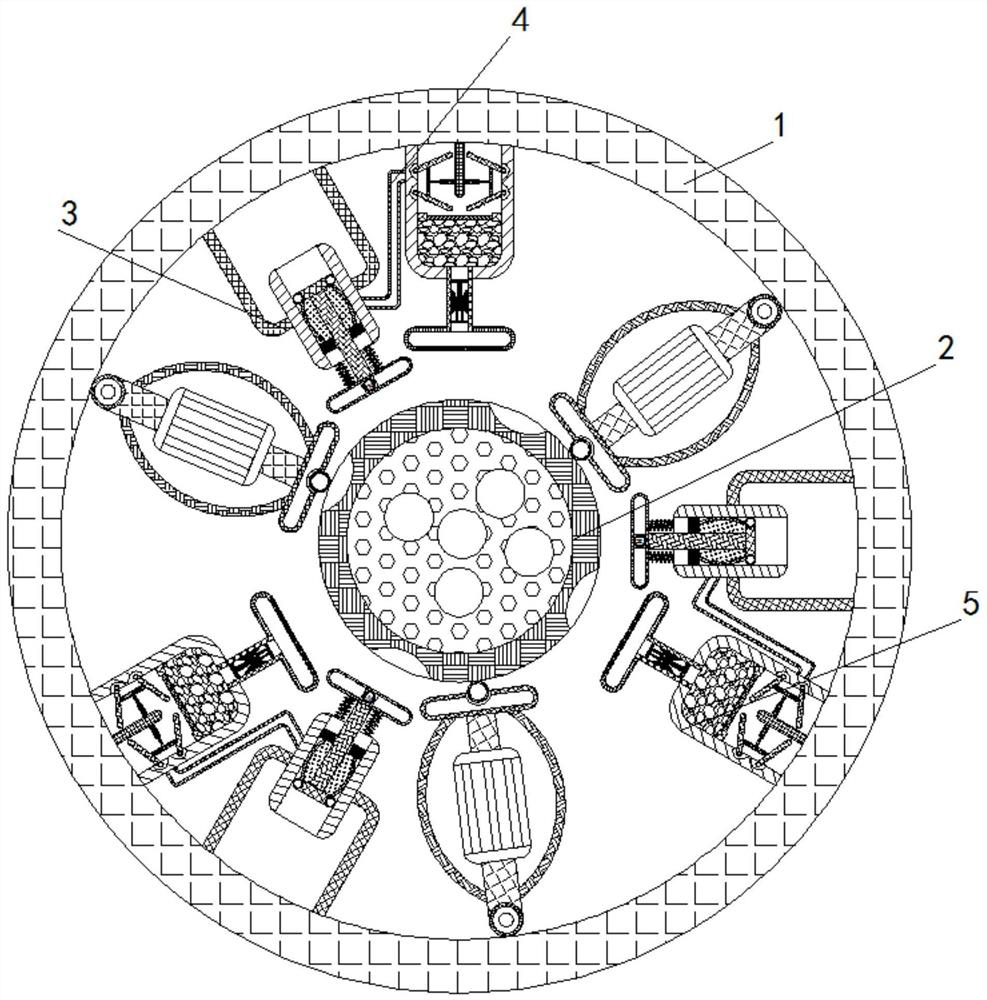

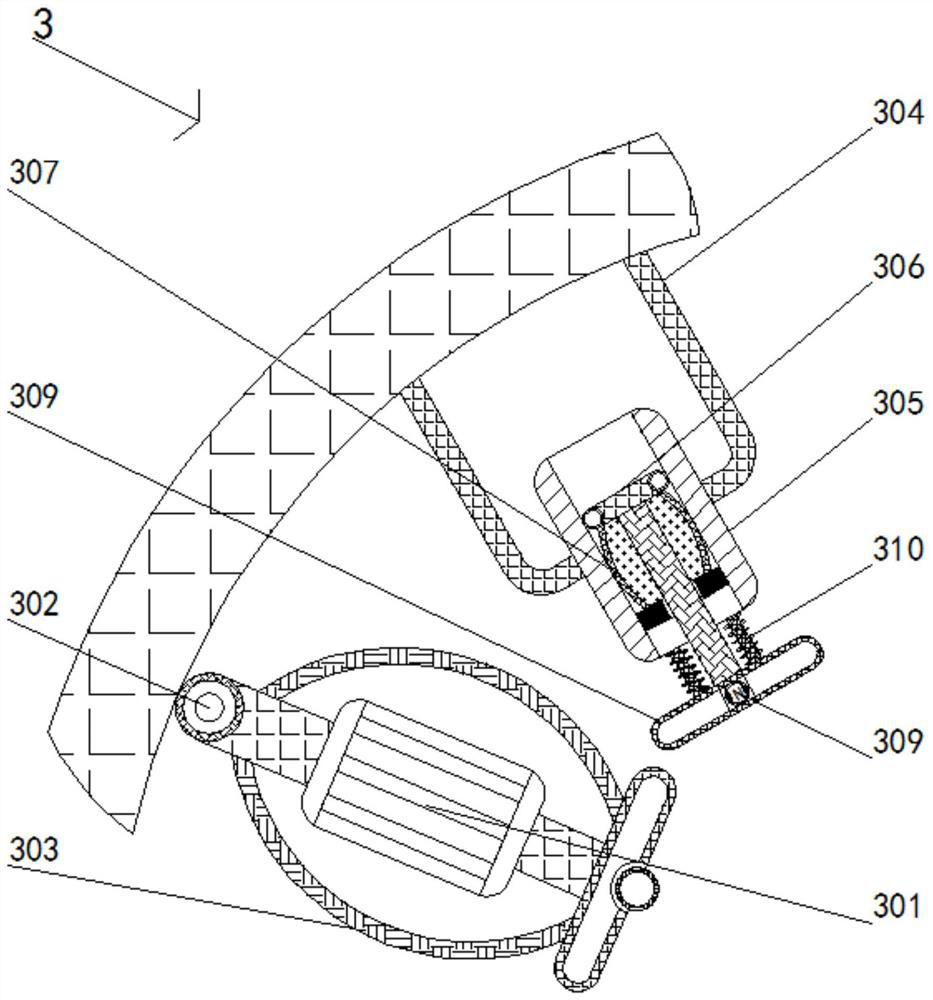

[0026] see Figure 1-2 , an equipment for detecting and automatically repairing the cable insulation layer, comprising a cable repairing equipment main body 1, a cable 2 is plugged inside the cable repairing equipment main body 1, a detection mechanism 3 is welded inside the cable repairing equipment main body 1, and the detection mechanism 3 There is an air duct 4 welded on the right side of the body, a motor 301 is welded inside the detection mechanism 3, a friction wheel 302 is welded on the top of the motor 301, conductive wires 303 are welded on the left and right sides of the friction wheel 302, and a bracket is welded inside the detection mechanism 3 304, the bottom of the bracket 304 is welded with a piston cylinder 305, the inside of the piston cylinder 305 is slidably connected with an extrusion rod 306, the inside of the piston cylinder 305 is welded with an air bag 307, the bottom of the extrusion rod 306 is welded with an adsorption plate 308, and the adsorption pl...

Embodiment 2

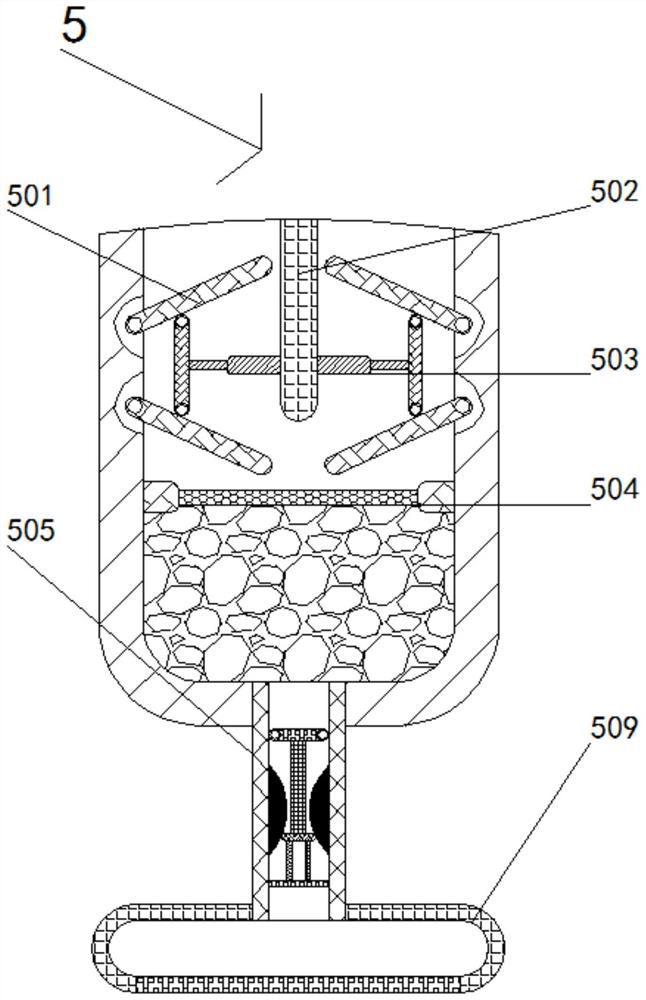

[0029] see Figure 3-4 , a kind of equipment for cable insulation detection and automatic repair, the inner wall of the repair mechanism 5 is rotatably installed with a rotating plate 501, the top of the repair mechanism 5 is welded with a fixing frame 502, and the left and right sides of the fixing frame 502 are welded with telescopic rods 503, The interior of the repairing mechanism 5 is welded with a push plate 504, the bottom of the repairing mechanism 5 is welded with a catheter 505, the inner wall of the catheter 505 is welded with a valve 506, and the inside of the valve 506 is slidably connected with a valve block 507. A sliding rod 508 is slidably connected inside, and a nozzle 509 is welded on the bottom of the catheter 505 .

[0030] The gas is introduced into the telescopic rods 503 on the left and right sides of the fixed frame 502 through the air duct 4, so that the telescopic rods 503 will stretch out, and the rotating plate 501 will be pushed and rotated by the...

Embodiment 3

[0032] see Figure 1-4 , an equipment for detecting and automatically repairing the cable insulation layer, comprising a cable repairing equipment main body 1, a cable 2 is plugged inside the cable repairing equipment main body 1, a detection mechanism 3 is welded inside the cable repairing equipment main body 1, and the detection mechanism 3 The right side of the cable is welded with an air duct 4, and the interior of the main body 1 of the cable repair equipment is welded with a repair mechanism 5.

[0033] Preferably, the inside of the detection mechanism 3 is welded with a motor 301, the top of the motor 301 is welded with a friction wheel 302, the left and right sides of the friction wheel 302 are welded with conductive wires 303, the inside of the detection mechanism 3 is welded with a bracket 304, and the bottom of the bracket 304 A piston cylinder 305 is welded, and the inside of the piston cylinder 305 is slidably connected with an extrusion rod 306. The extrusion rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com