Constant-tension cloth feeding mechanism for printing machine

A cloth feeding mechanism and constant tension technology, applied in mechanical cleaning, high pressure cleaning, textile and papermaking, etc., can solve the problems of easy wrinkling, poor printing, affecting product quality, etc., to achieve convenient tension, ensure flatness, The effect of high practicality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

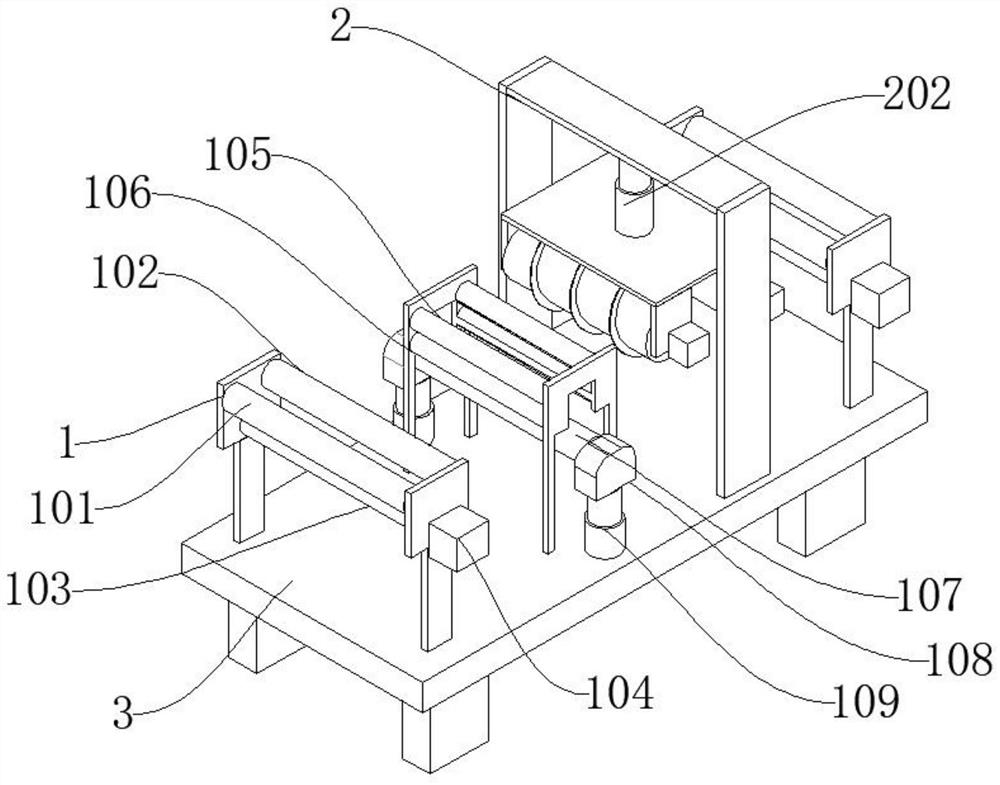

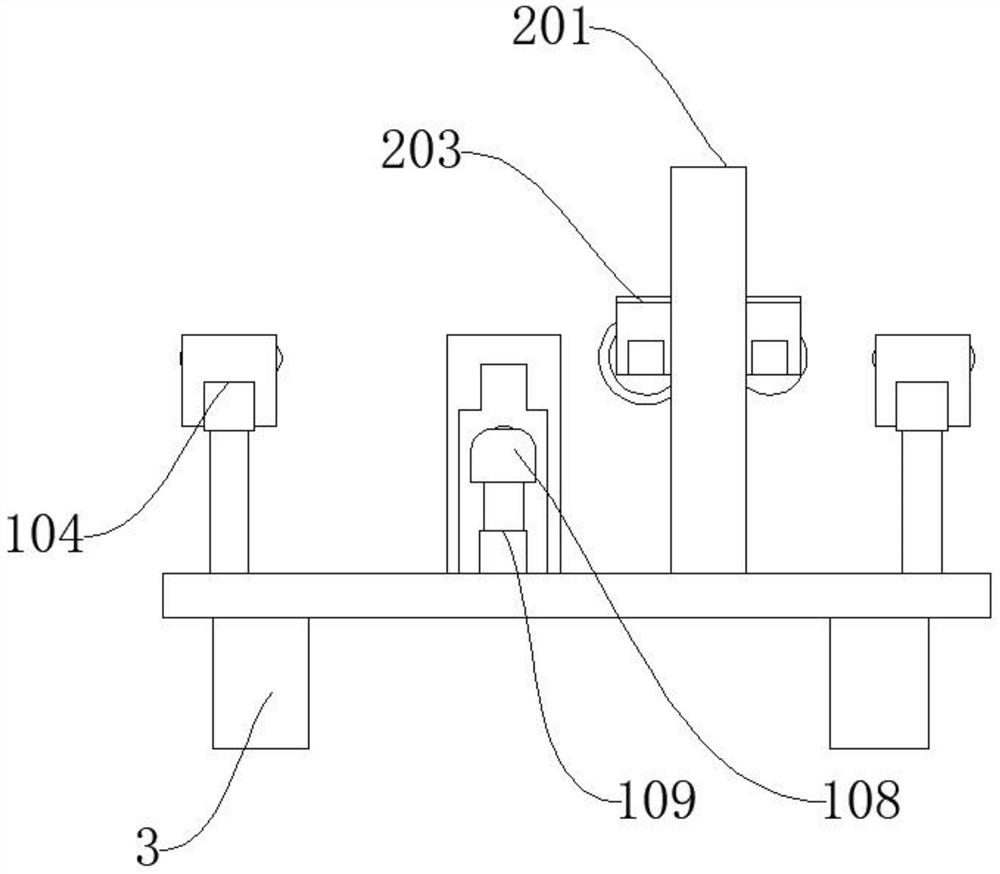

[0025] Such as figure 1 , figure 2 , image 3 , Figure 4 As shown, the present invention provides a technical solution: a constant tension cloth feeding mechanism for printing machines, including a base 3, a transmission mechanism 1 is arranged on the base 3, a cleaning mechanism 2 is arranged on one side of the transmission mechanism 1, and the transmission mechanism 1 includes a Conducting column 101, No. 2 conducting column 102, No. 3 conducting column 103, No. 2 conducting column 102 is arranged on one side of No. 1 conducting column 101, No. 3 conducting column 103 is arranged under No. 1 conducting column 101, and No. 3 conducting column 103 No. 1 motor 104 is installed at the top, No. 2 conducting column 102 is provided with an upper guide roller 105 away from No. 1 conducting column 101, a lower guide roller 106 is installed below the upper guide roller 105, and an adjusting roller 107 is arranged below the lower guide roller 106. Mounting seat 108 is installed on...

Embodiment 2

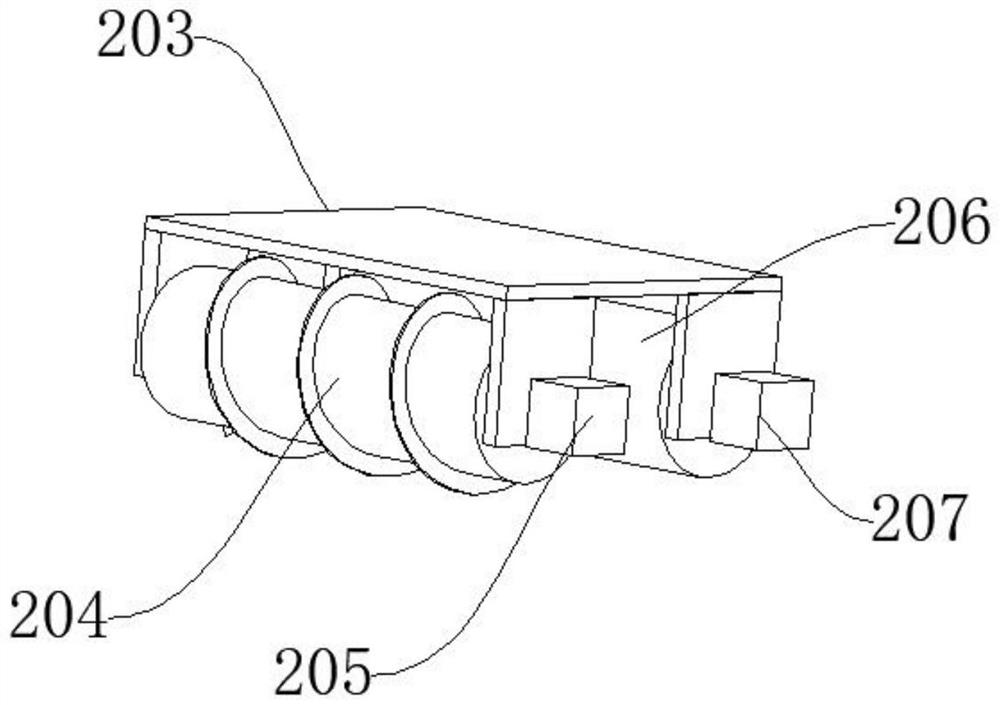

[0029] Such as Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that the cleaning mechanism 2 includes a support 201, No. 2 electric telescopic column 202, and a mounting frame 203, and No. 2 electric telescopic column 202 is installed on the inside of support 201, and No. 2 electric telescopic column 202 Mounting frame 203 is installed on the lower end, and carding roller 204 is installed in mounting frame 203 inner side, and No. 2 motor 205 is installed on carding roller 204 front, and electrostatic adsorption net 208 is installed on carding roller 204 one side.

[0030] No. 3 motor 207 is driven to stick the hair roller 206 to rotate, stick the fluff on the cloth, and replace it with the electrostatic adsorption net 208 to absorb the fluff on the cloth passing below.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com