5G high-frequency microwave copper-clad plate continuous packaging device and using method

A high-frequency microwave and copper clad laminate technology, applied in the field of 5G high-frequency microwave copper clad laminate continuous packaging devices, can solve the problems of low manufacturing efficiency, decline in the quality of copper clad laminates, poor screening effect, etc., to improve efficiency, improve accuracy, Guaranteed accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

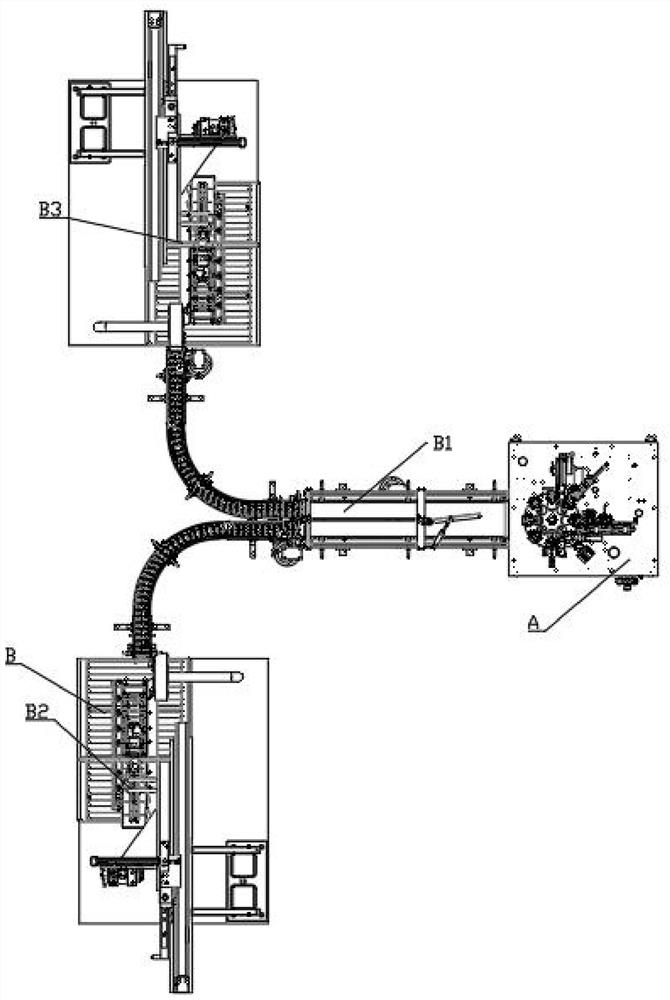

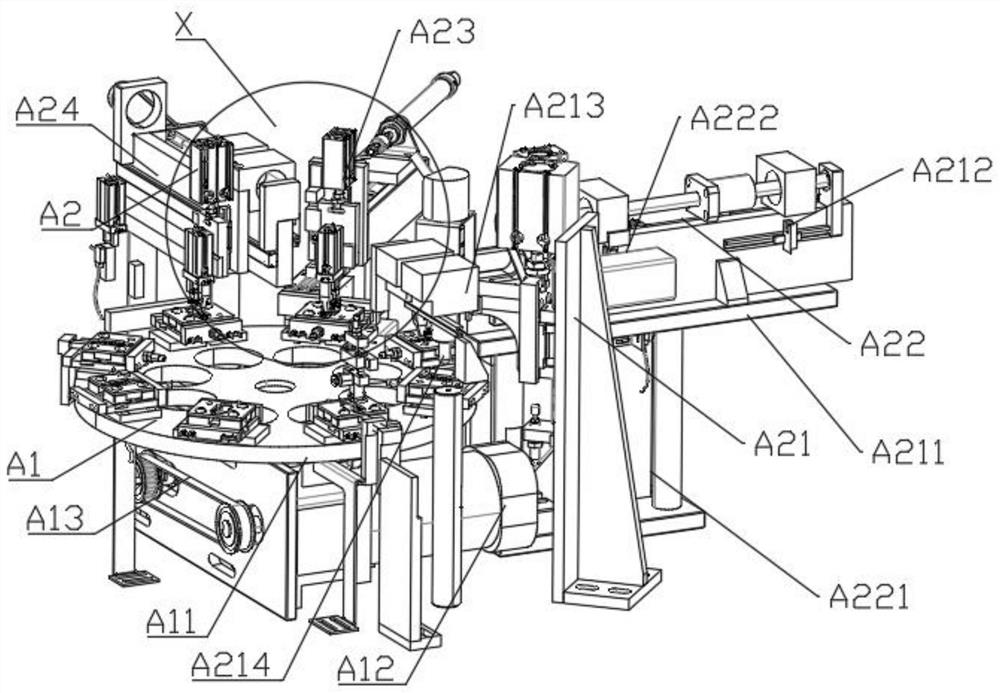

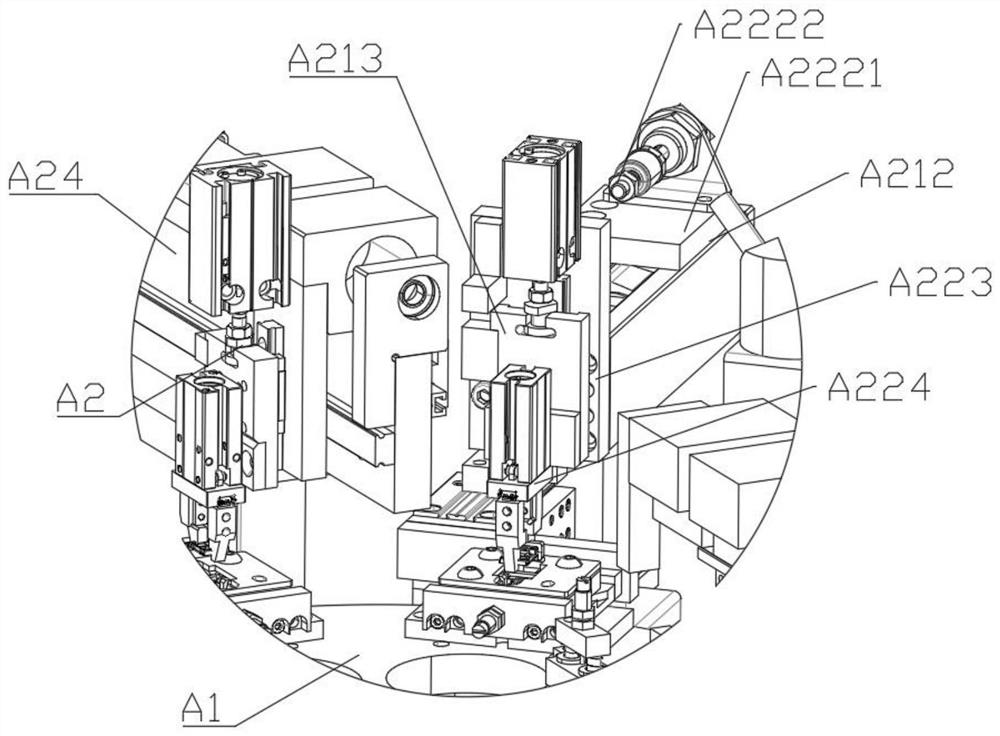

[0069] Such as Figure 1-10 As shown, a 5G high-frequency microwave continuous packaging device for copper-clad laminates, including a material sorting device A, a material delivery device B, and the left part of the material sorting device A is fixedly connected to the material delivery device B;

[0070] The material sorting device A includes a material sorting tray A1 and a material sorting component A2, and the material sorting component A2 is arranged above the material sorting tray A1. The copper clad laminate raw materials arrive at the packing station under the action of the conveying mechanism, where packing personnel are specially arranged to manually push the packing box into the packing machine for packing, and then push the packed packing box into the next conveying mechanism. Since the packaging process is intermittent, the packaging box must be manually pushed in when entering the packaging machine. The conveying mechanism in the prior art cannot connect its own...

Embodiment 2

[0075] This embodiment is a further improvement of the previous embodiment, such as Figure 1-10 As shown, a 5G high-frequency microwave continuous packaging device for copper-clad laminates, including a material sorting device A, a material conveying device B, and the left part of the material sorting device A is fixedly connected to the material conveying device B;

[0076] The material sorting device A includes a material sorting tray A1 and a material sorting component A2, and the material sorting component A2 is arranged above the material sorting tray A1. The copper clad laminate raw material arrives at the packing station under the action of the conveying mechanism, where packing personnel are specially arranged to manually push the packing box into the packing machine for packing, and then push the packed packing box into the next conveying mechanism. Since the packaging process is intermittent, the packaging box must be manually pushed in when entering the packaging m...

Embodiment 3

[0084] This embodiment is a further improvement of the previous embodiment, such as Figure 1-10 As shown, a 5G high-frequency microwave continuous packaging device for copper-clad laminates, including a material sorting device A, a material conveying device B, and the left part of the material sorting device A is fixedly connected to the material conveying device B;

[0085] The material sorting device A includes a material sorting tray A1 and a material sorting component A2, and the material sorting component A2 is arranged above the material sorting tray A1. The copper clad laminate raw material arrives at the packing station under the action of the conveying mechanism, where packing personnel are specially arranged to manually push the packing box into the packing machine for packing, and then push the packed packing box into the next conveying mechanism. Since the packaging process is intermittent, the packaging box must be manually pushed in when entering the packaging m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com