Conical cabin butt joint multi-freedom-degree adjusting device

A technology for adjusting devices and degrees of freedom, applied in hand-held tools, manufacturing tools, etc., can solve problems such as low work efficiency, high risk of installation quality, and high intensity of installation operations, and achieve high docking efficiency, eliminate potential safety hazards, and reduce labor intensity. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

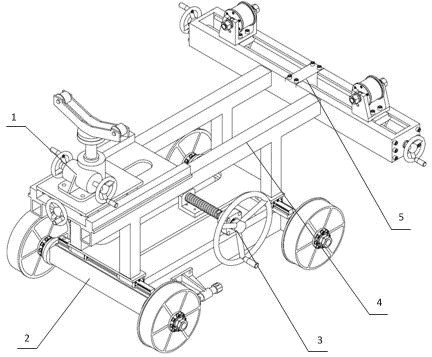

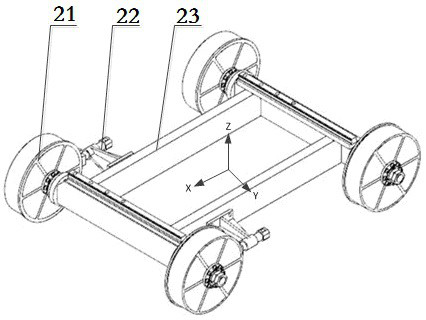

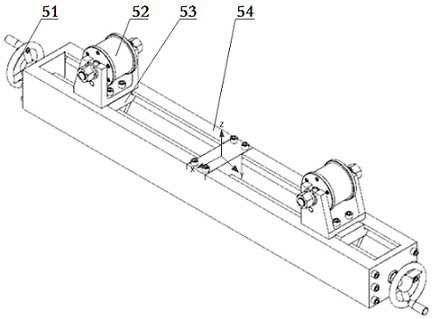

[0037] The present invention provides a tapered adjustment means cabin butt freedom. The device is mainly used at all levels of conical or cylindrical thrust cartridge holder segment or other tooling missile, instrument cabin, and a solid support such as an engine assembly attitude adjustment, a mobile station back and forth along the track member, lateral movement, vertical movement, about the axis rotation function, and the pitch adjustment and horizontal swinging adjustment abutment surfaces. Conical butt cabin DOF adjustment means by a rail wheel assembly support frame, subsystems traverse mechanism, a head elevating mechanism, the center of the bidirectional adjustment mechanism or the like. For different types and sizes of the engine, front and rear support frame is modular in design, the replacement of different front and rear support frame module can accommodate various installation engine thrust frame.

[0038] For purposes of the present invention, features and advantage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com