Double-sided flexible circuit board SMT magnetic patch jig

A flexible circuit board and magnetic patch technology, applied in the direction of electronic circuit testing, measuring device casing, etc., can solve the problems of scratches on the surface of the circuit board, damage to the circuit board, inconvenience, etc. Scratched for easy insertion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

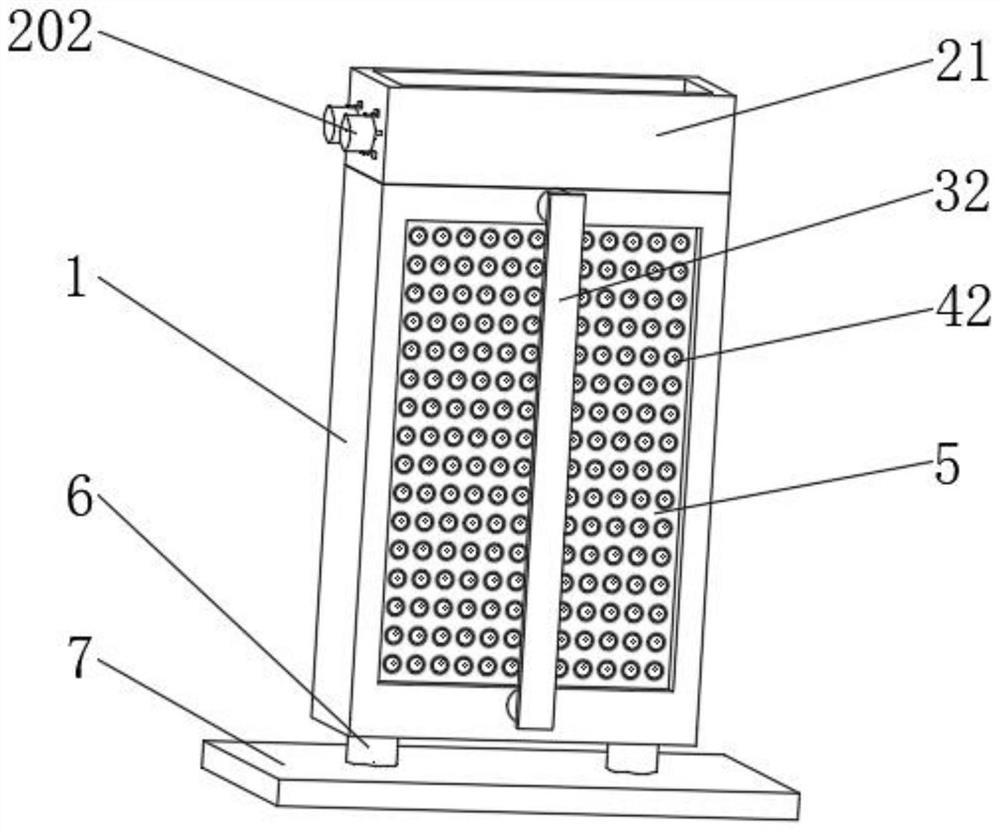

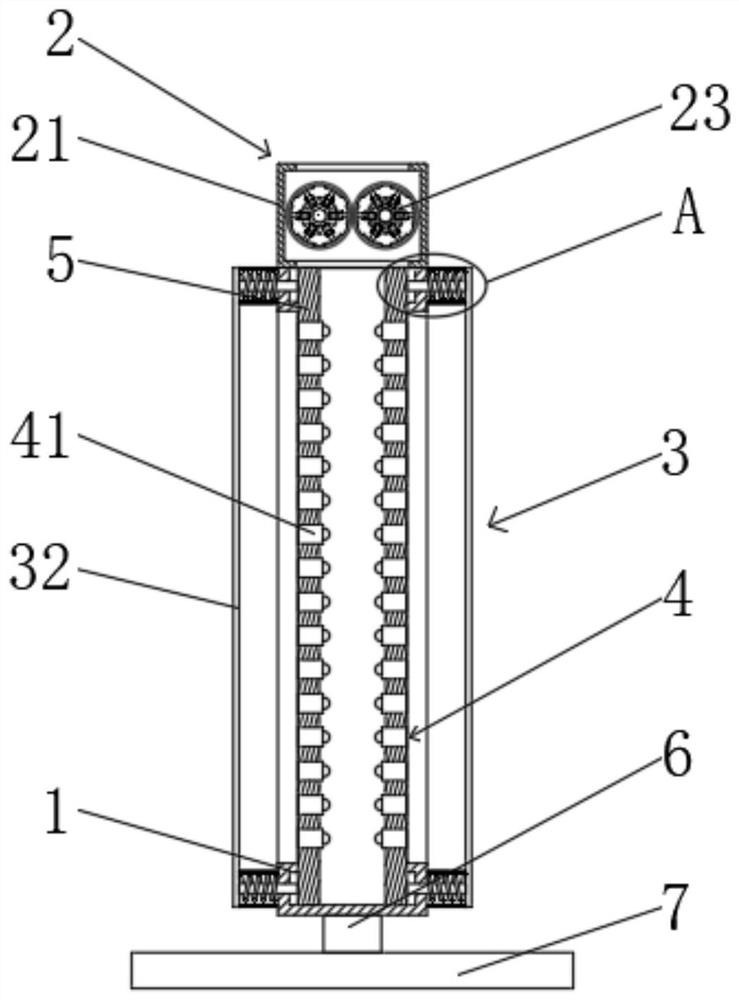

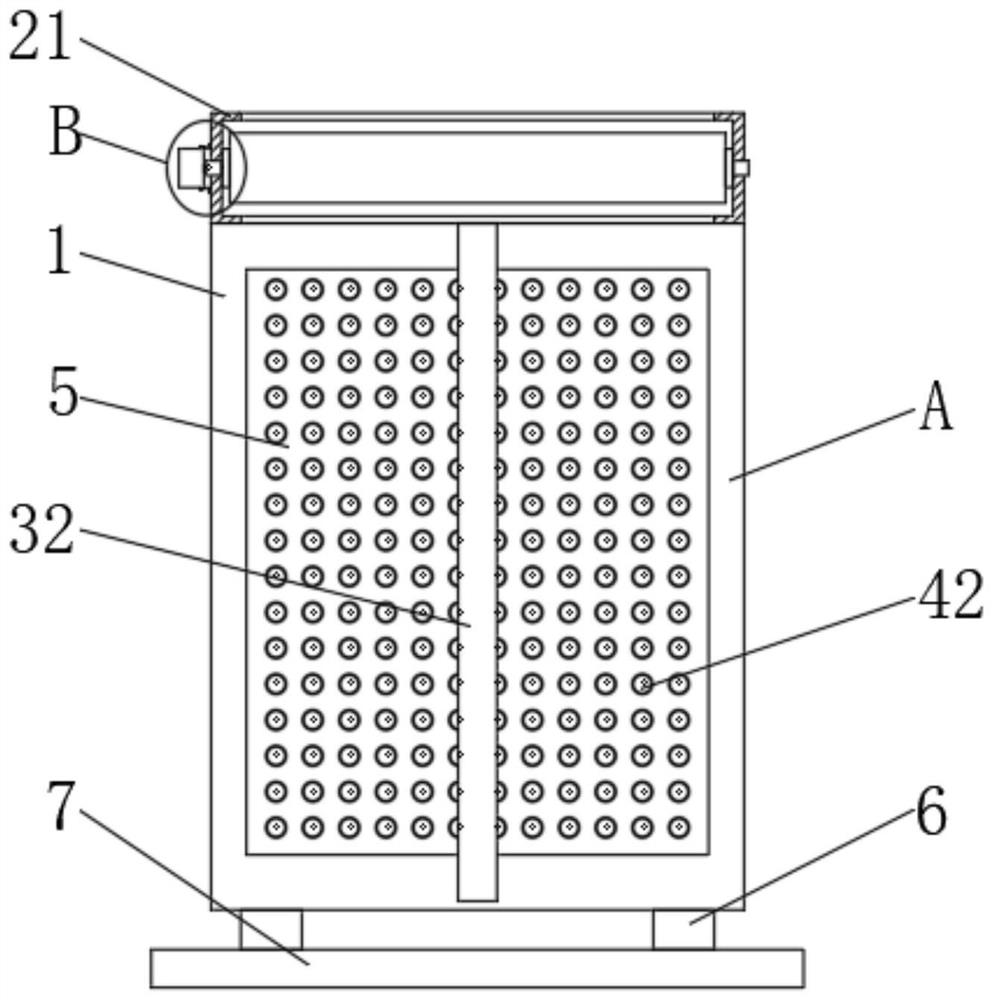

[0027] A double-sided flexible circuit board SMT magnetic patch fixture, including a housing 1, a driving mechanism 2, a detection mechanism 3, a connecting mechanism 4, a moving plate 5, a supporting column 6, and a bottom plate 7, the upper end of the housing 1 is provided with a drive Mechanism 2, the casing 1 is provided with a detection mechanism 3, the inside of the casing 1 is slidingly connected with two symmetrically distributed moving plates 5, the inside of the moving plate 5 is provided with a connecting mechanism 4, and the inside of the casing 1 The lower end is fixedly connected with a support column 6, and the number of the support column 6 is two, and the two support columns 6 are distributed symmetrically at the lower end of the housing 1, and the lower ends of the two support columns 6 are jointly fixedly connected with a bottom plate 7. The bottom plate 7 can make the placement of the housing 1 more stable.

[0028] Wherein, the drive mechanism 2 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com