Imaging method and device based on ultrasonic Lamb wave defect detection

A technology of ultrasonic lamb wave and defect detection, which is applied in the direction of analyzing solids using sound waves/ultrasonic waves/infrasonic waves, and can solve the problems of inability to form high-resolution detection images, failure to form high-resolution detection images, and ignoring useful information, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The technical solutions of the present application will be described in further detail below with reference to the drawings and embodiments.

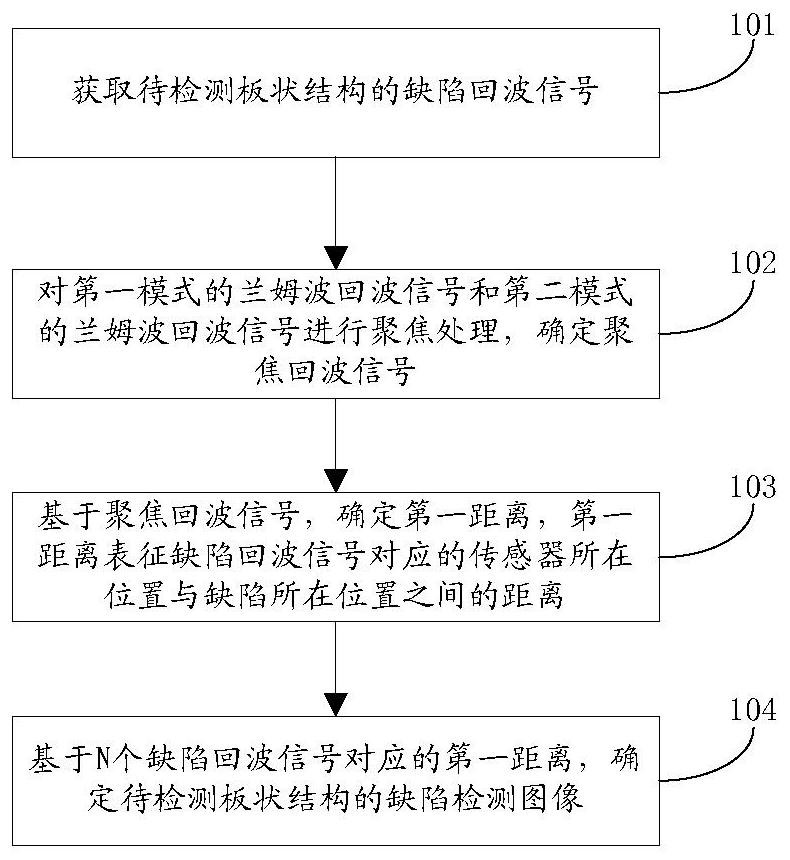

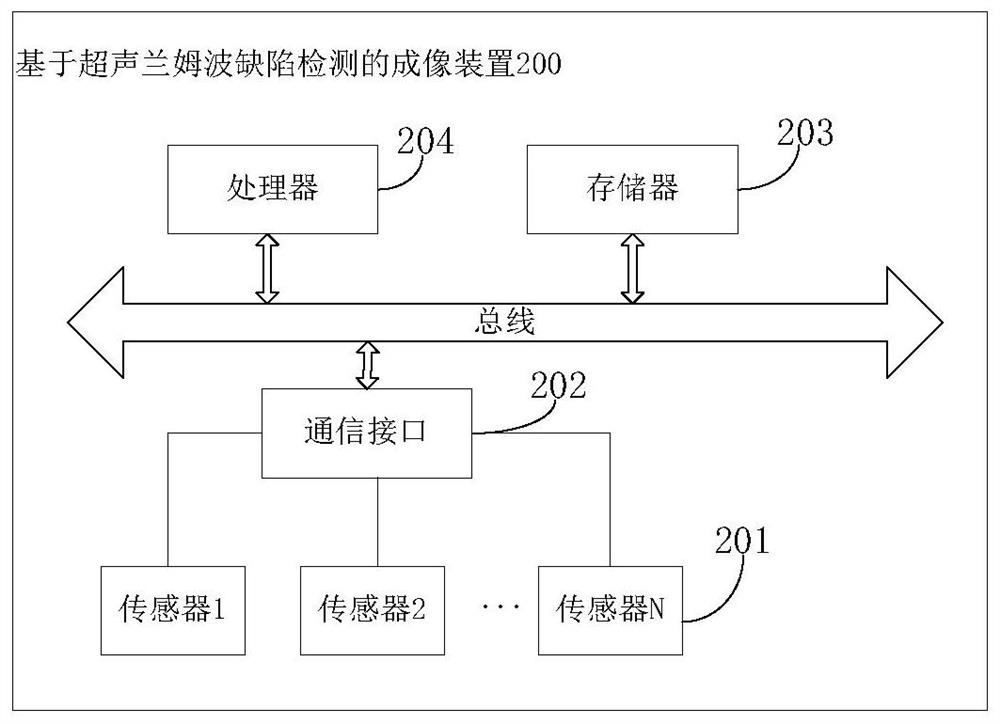

[0046] figure 1 The flow chart of the imaging method based on ultrasonic Lamb wave defect detection provided by the embodiment of this application. Such as figure 1 As shown, the method includes step S101-step S104.

[0047] In step S101, the defect echo signal of the plate structure to be detected is acquired.

[0048] Exemplarily, the probe is fixed on the plate-like structure to be detected, N sensors are arranged in the region of interest (that is, the region to be detected) of the plate-like structure to be detected, and ultrasonic Lamb waves are generated by excitation of the probe. When the plate-like structure to be detected When there is a defect in the plate-shaped structure, N sensors receive defect echo signals, and the defect echo signals of the plate-shaped structure to be detected are obtained by acquiring the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com