Reciprocating novel pump with double-screw transmission structure device

A transmission structure, double-helix technology, applied to the components, pumps, pump components and other directions of the pumping device for elastic fluid, can solve the problems of unsuitable use, large overall volume, difficult disassembly and assembly, etc., to achieve product reliability, Small size, the effect of reducing maintenance frequency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] This embodiment mainly introduces the working principle of the reciprocating pump.

[0048] Please refer to figure 1 , figure 1 Schematic diagram of the working principle of a reciprocating pump.

[0049] The reciprocating pump is driven by a motor, and the crankshaft is driven to rotate through gear reduction. When the crankshaft rotates, the slider and the plunger are driven to reciprocate, so that the working fluid is sucked and discharged through the suction and discharge check valve in the pump head. The electrical energy is converted into mechanical energy, and then converted from mechanical energy into hydraulic energy, and the output pressure liquid is used for the hydraulic support of the working face.

[0050] This embodiment simply introduces the operating principle of the reciprocating pump, so as to facilitate the understanding of the structure of the reciprocating pump of a novel double-screw transmission structure device of the present invention.

Embodiment 2

[0052] Based on the above-mentioned embodiment 1, this embodiment mainly introduces the structure of a reciprocating pump with a new double-screw transmission structure device.

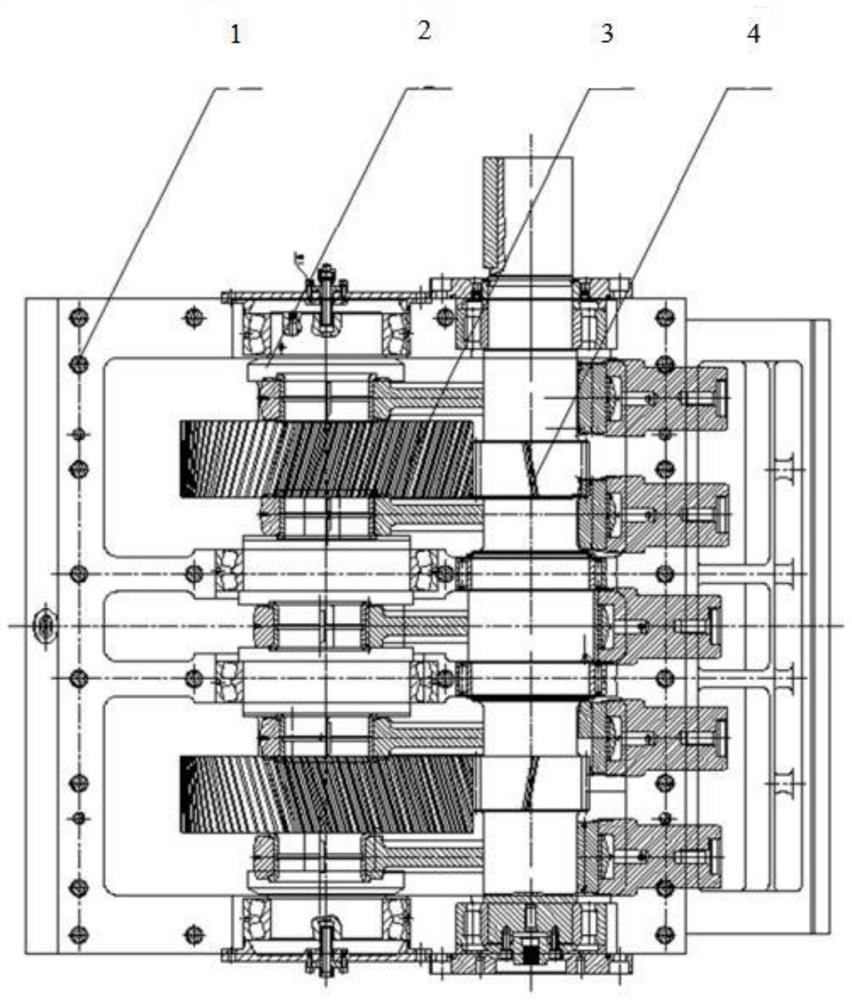

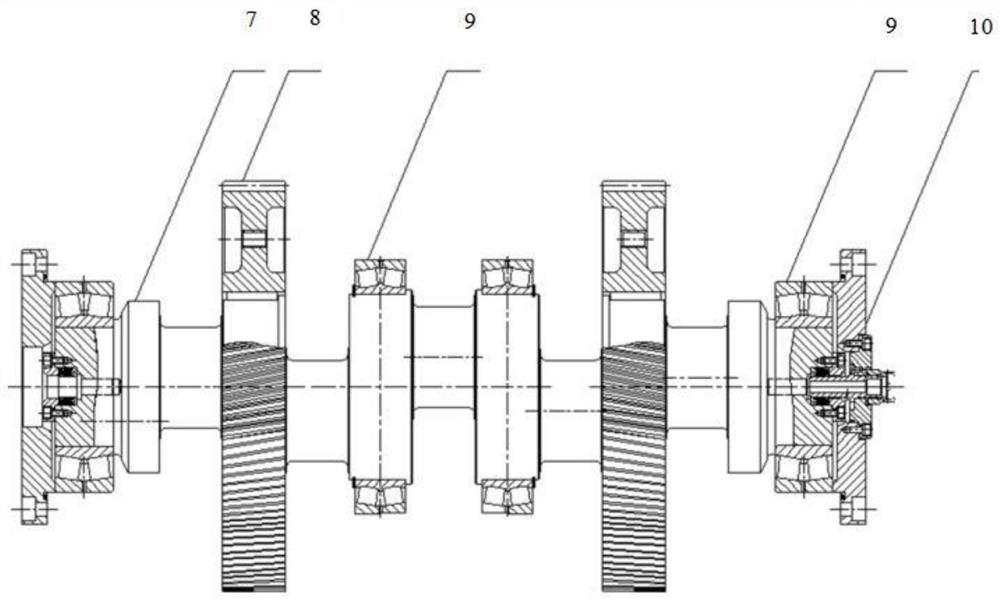

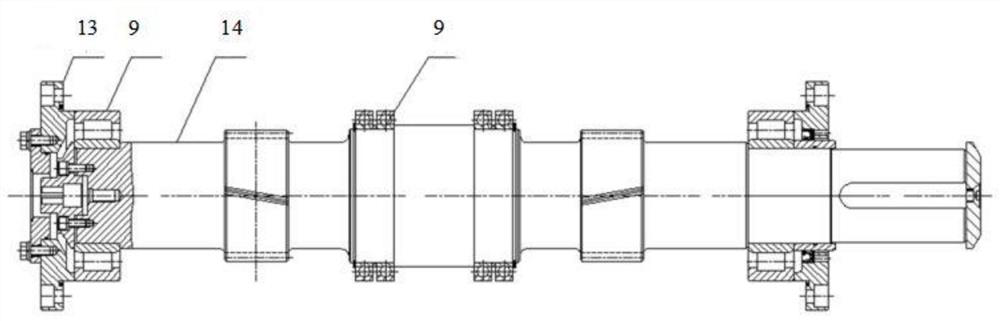

[0053] Please refer to Figure 2-8 , figure 2 Front view of a reciprocating pump of a novel double-screw transmission structure device provided by the present invention;

[0054] image 3 A top view of the reciprocating pump power end of a novel double-screw transmission structure device provided by the present invention; Figure 4 A reciprocating pump box diagram of a novel double-screw transmission structure device provided by the present invention; Figure 5 A diagram of the reciprocating pump crankshaft assembly of a novel double-helical transmission structure device provided by the present invention; Image 6 A diagram of the reciprocating pump pinion shaft assembly of a novel double-helical transmission structure device provided by the present invention; Figure 7 A diagram of the liquid e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com