Controllable two-way grout stopping device for sleeve valve pipe

A sleeve valve tube and slurry stop technology is applied in the field of controllable two-way slurry stop devices, which can solve the problems of high grouting pressure, failure to reset the slurry stop plug, and the slurry stop plug stuck in the tube, and achieves the effect of improving stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

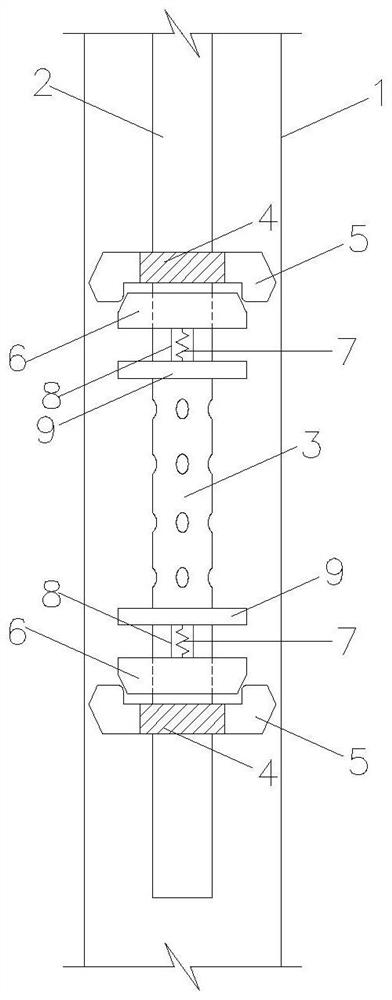

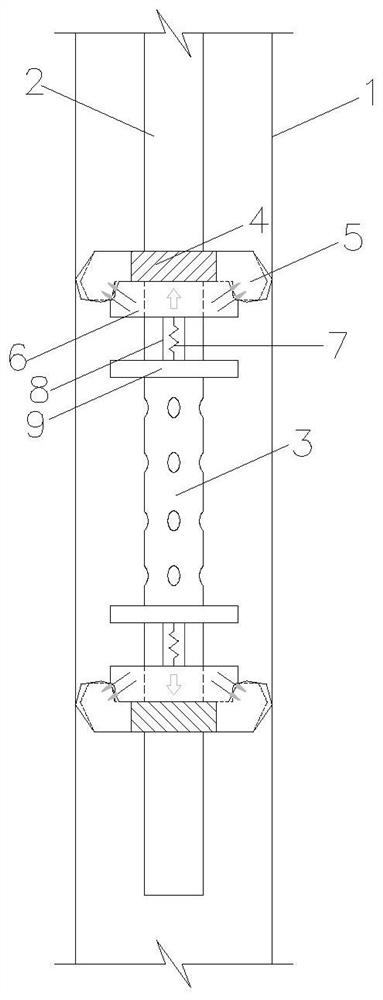

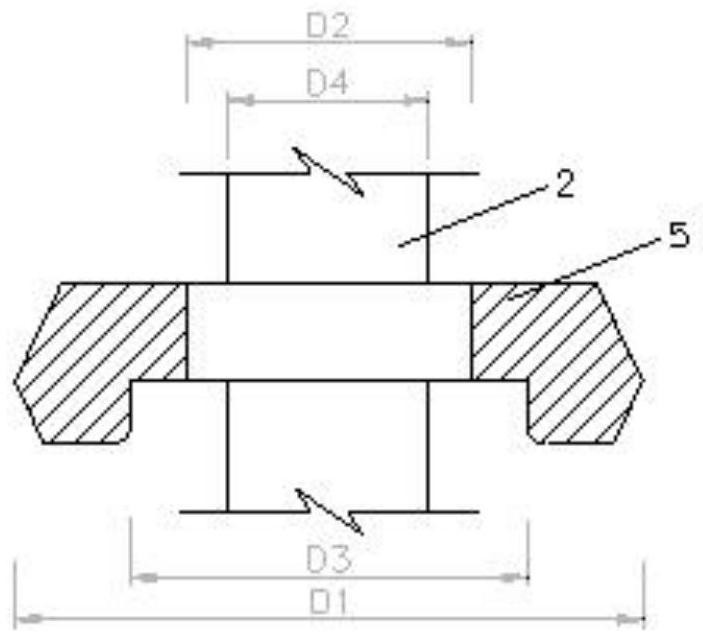

[0026] This embodiment provides a controllable two-way slurry stop device for the sleeve valve tube, such as Figure 1-7 As shown, the metal stopper 9, the return spring group 7, the round table metal slider 6, the polyurethane grout stopper, and the ring-shaped suction cup electromagnet 4 are arranged sequentially outward from both sides of the grouting steel flower tube 3. The suction cup electromagnet 4 is connected with the outside 24V DC power supply and the electromagnet switch through the lead wire; in the working state, the ring-shaped suction cup electromagnet is connected with the corresponding round table metal slider, and one end of the round table metal slider is pushed into the polyurethane stop In the groove of the grout plug, the polyurethane grout stopper is in close contact with the wall of the sleeve valve pipe, and the other end of the metal slider of the round table is connected with the limit stopper through the return spring group, and the limit stopper i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com