Fire preventing and extinguishing type strong reinforcing material for underground space filling, and preparation method and application thereof

An underground space and reinforcement material technology, which is applied in the direction of fire prevention equipment, etc., can solve the problems of lining fracture, fireproof and flame retardant lining easy expansion, reinforcement instability, etc., to achieve the effect of repairing cracks, improving fire extinguishing performance, and improving reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

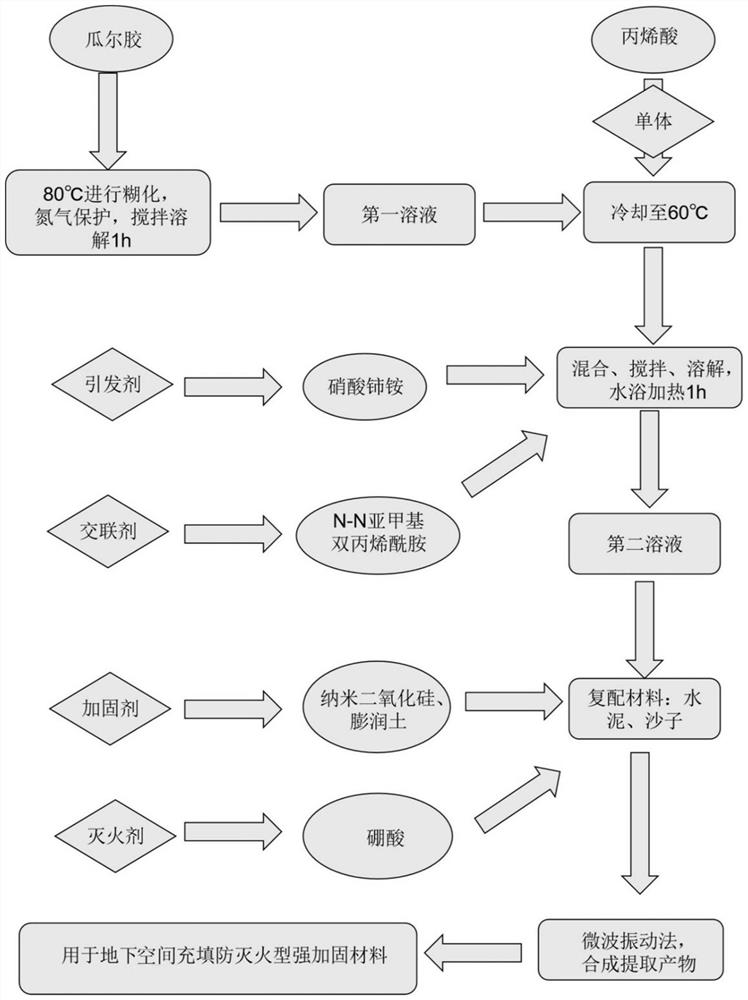

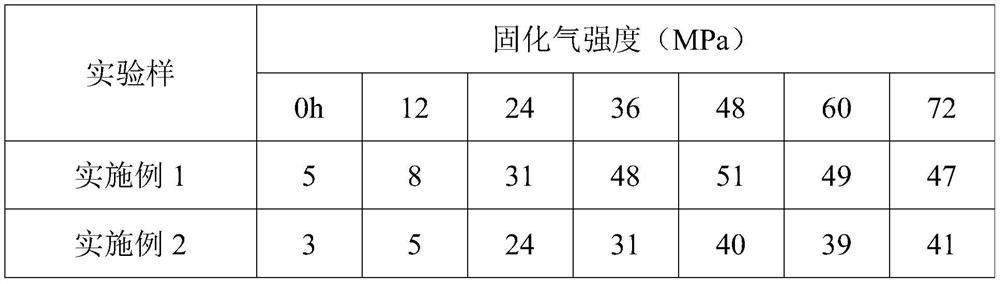

[0034] Weigh 2g of guar gum and put it into a three-neck flask with 70ml of distilled water, and pass through nitrogen gas, and gelatinize at 80°C for 1.5h. After gelatinization, adjust the temperature to 60°C, add 8g of acrylic acid while stirring, and after it is completely dissolved, add 0.5g of cerium ammonium nitrate and keep the water bath heated; then add 1.5g of N-N methylenebisacrylamide, Mix and stir to dissolve for 1 hour, then pour it into the mixed material of 100g cement, 300g sand, 6g nano-silicon dioxide, 8g bentonite and 4g boric acid and stir to make it evenly mixed; The power ratio is set to 40% for vibration synthesis to obtain a fire-proof strong reinforcement material for underground space filling. Final test related performance.

Embodiment 2

[0036] Weigh 2g of guar gum into a three-neck flask with 70ml of distilled water, blow nitrogen into it, and gelatinize at 80°C for 1.5h. After gelatinization, adjust the temperature to 60°C, add 4g of acrylic acid while stirring, and then add 0.5g of cerium ammonium nitrate after it is completely dissolved, and keep the water bath heating; then add 1.5g of N-N methylenebisacrylamide, Mix and stir to dissolve for 1 hour, then pour it into the mixed material of 100g cement, 300g sand, 6g nano-silicon dioxide, 8g bentonite and 4g boric acid and stir to make it evenly mixed; The power ratio is set to 40% for vibration synthesis to obtain the fire-proof and extinguishing strong reinforcement material for underground space filling. Final test related performance.

Embodiment 3

[0038] Weigh 2g of guar gum into a three-necked flask with 70ml of distilled water and pass through nitrogen, and gelatinize at 80°C for 2h. After gelatinization, adjust the temperature to 30°C, add 8g of acrylic acid while stirring, and after it is completely dissolved, add 0.5g of cerium ammonium nitrate and keep the water bath heated; then add 1.5g of N-N methylenebisacrylamide, Mix and stir to dissolve for 1 hour, then pour it into the mixed material of 100g cement, 300g sand, 6g nano-silicon dioxide, 8g bentonite and 4g boric acid and stir to make it evenly mixed; The power ratio is set to 40% for vibration synthesis to obtain the fire-proof and extinguishing strong reinforcement material for underground space filling. Final test related performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com