Adjustable high-precision combined reamer

A high-precision, adjustable technology, used in reamers, metal processing equipment, manufacturing tools, etc., can solve problems such as poor stability, affect machining accuracy, and affect hole machining accuracy, reduce coaxiality errors, and improve coaxiality. The effect of improving the accuracy and improving the machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment approach

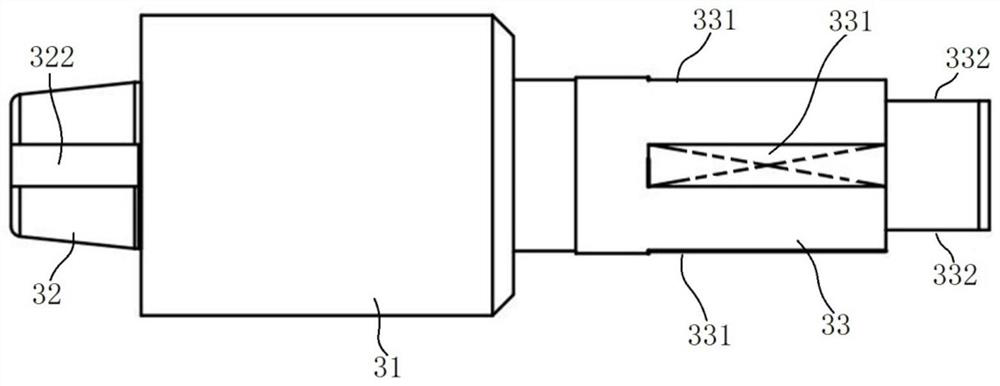

[0045] A kind of embodiment of the present invention: the combination reamer of the present invention can be used for processing the hole of high precision, and the rotating speed can be as high as 3000-4000 rev / min, and the roughness of the hole that it can process, can guarantee in Ra0 for ductile iron Within .3 (the smallest reamer on the market is also above Ra1.0), the roughness of steel parts can reach Ra0.007 (the smallest reamer on the market is also around Ra0.4), and the difference between the upper and lower diameters of the machinable holes should not exceed 6μm, high-precision holes with a cylindricity of no more than 5μm. The combination reamer not only guarantees the high-precision characteristics of the integral cutter head, but also has the characteristics of economical and convenient replacement of the split cutter head, and the cutter bar can also adjust the coaxiality and reaming between the entire reamer and the tool handle of the equipment. The coaxiality...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com