Method and system for preparing electrode plate by dry process, and application

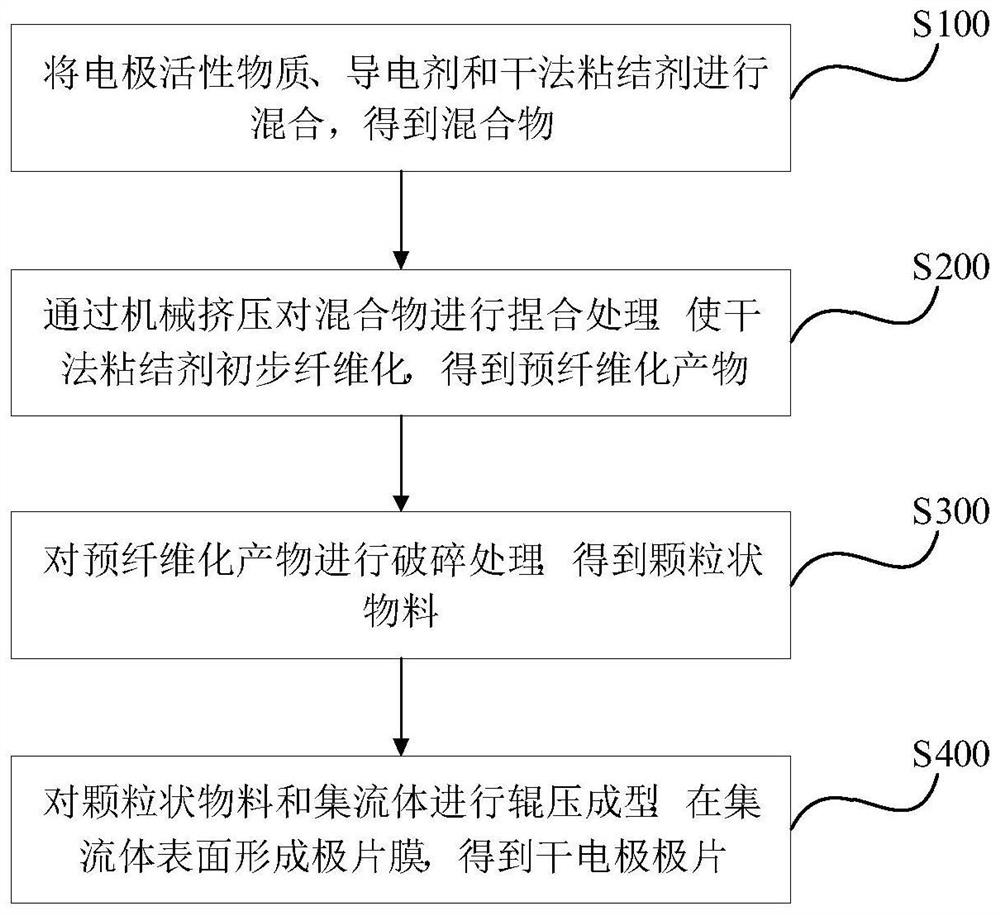

A technology for preparing electrodes and dry method, which is applied in the field of electrode sheet preparation by dry method, can solve the problems that the structure of electrode active materials is easily destroyed, and the electrochemical performance of batteries or supercapacitors decreases, so as to facilitate film formation by rolling and improve fiber effects and reduce adverse effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] (1) Mix the electrode active material, conductive agent, and dry binder using a mixing device to obtain a mixture, wherein the electrode active substance is an NCM523 positive material, the conductive agent is SP (super carbon black), dry binder For PTFE, the mass ratio of the three is 97: 1: 2;

[0083] (2) The mixture is kneaded by a kneading apparatus having a pair of σ-shaped rotary blades arranged in combination with each other, and the dry binder is preliminary, and the pre-fibrotic product, two blades The rotational speed is 42 rpm, respectively, and 28 rpm.

[0084] (3) The preframe was crushed by a crusher to obtain a particulate material, in which the rotational speed of the crusher was 500 rpm, and the particulate material was sieved using an 8 mesh screen, and the material was collected under the screen.

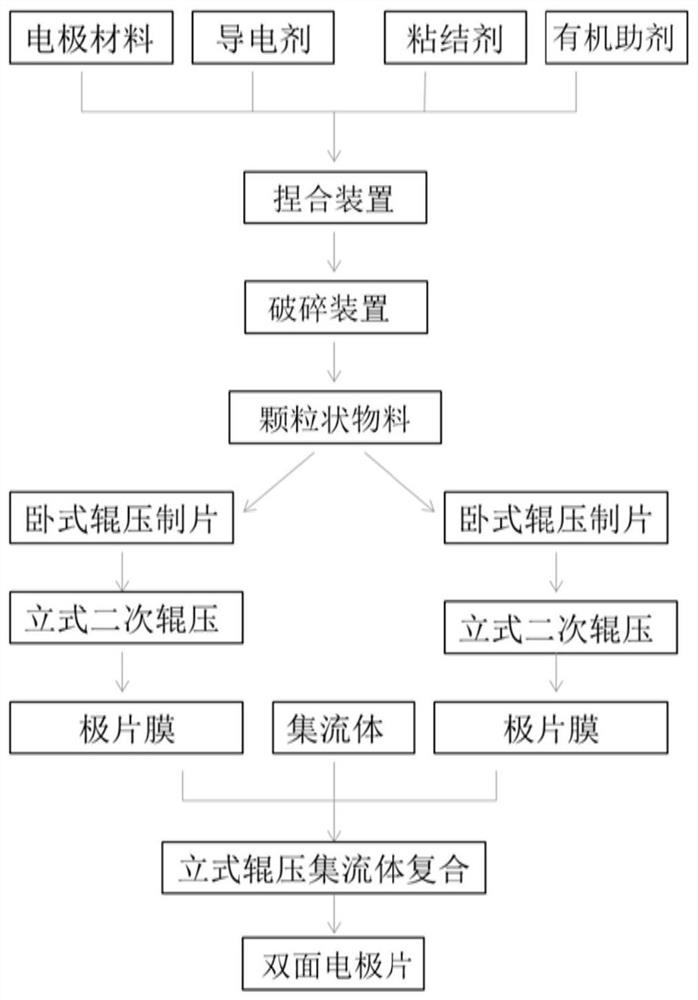

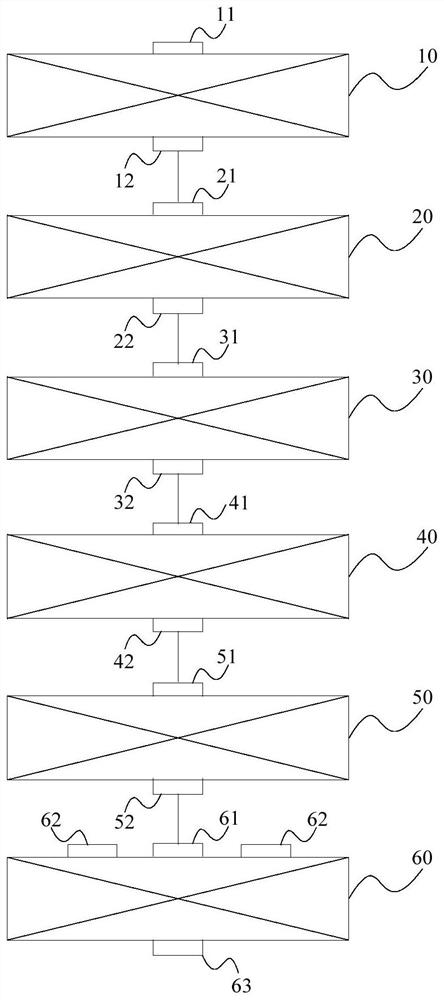

[0085](4) a horizontal heating roll press material after sieving is hot-pressed at 100 ℃, to give the primary pole pieces of the film; using a three-roll sets...

Embodiment 2

[0087] Example 1 in that the difference between: the step (2) is further added to the organic additives heterogeneous hexadecane (trade name Isopar M), the proportion of the organic additives in the mixture is 8wt%. Step (4) of a horizontal heat roll press material after sieving is hot-pressed at 100 ℃, to give the primary pole pieces of the film; using a three-roll sets of successive vertical roll press heated at 120 ℃ primary 3 batches pole piece film is heat accumulated nine roll forming, to obtain a film having a thickness of 80μm of the pole piece; positive electrode sheet membrane compaction density of 2.9g / cm 3 . 150 ℃ blast drying 4h, after removal of the auxiliary Isopar M, and using the film thickness of the pole pieces COATED vertical roll press heated at 120 deg.] C as 17μm sided aluminum foil current collector, the layer thickness of 2μm trampled hot pressed composite, to give sided pole piece, the pole piece thickness 159μm, pole piece tap density 3.3g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com