A support device for textile machinery

A technology of supporting device and textile machinery, applied in the directions of mechanical cleaning, textile and papermaking, transportation and packaging, etc., can solve problems such as inconvenience of use, and achieve the effect of ease of use, avoidance of excessive cleaning, and uniform cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

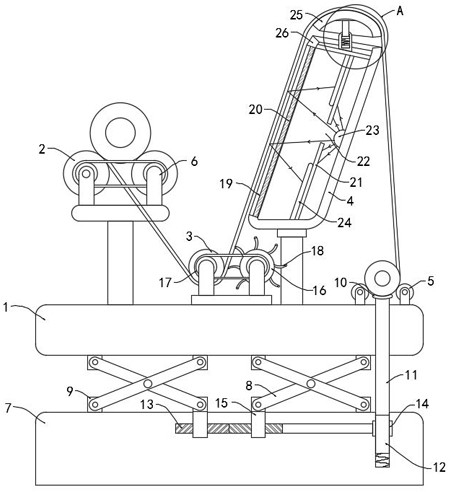

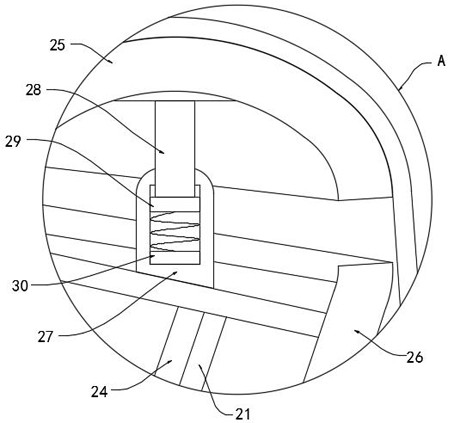

[0029] Such as Figure 1-2 As shown, a supporting device for a textile machine includes a horizontally arranged console 1, on which two driving rollers 2 arranged side by side, a steering roller 3, a light box 4 and two The accommodating roller 5 that is arranged side by side, above is prior art, does not repeat too much here.

[0030] The ends of the driving roller 2, the diverting roller 3 and the containing roller 5 are all rotatably connected with a strut 6, and the lower end of the strut 6 at the end of each driving roller 2 is jointly fixedly connected with a horizontally arranged bearing plate, and the bearing plate passes through its lower end vertically. The vertically arranged struts are fixedly connected to the console 1, and the other ends of the struts 6 at the ends of the steering roller 3 and the storage roller 5 are all fixedly connected to the console 1;

[0031] A support mechanism is provided below the console 1 to support the entire console, including a su...

Embodiment 2

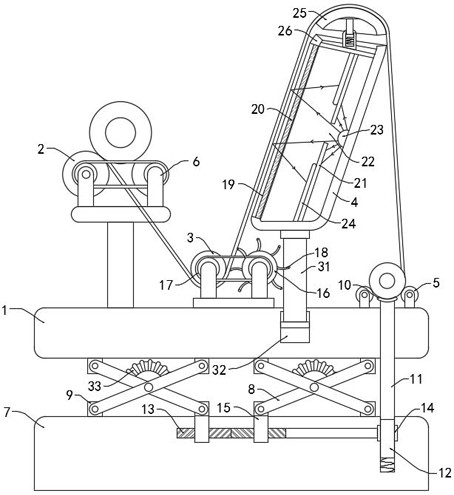

[0042] Such as image 3 As shown, the difference from Embodiment 1 is that the lower end of the light box 4 is connected with a connecting rod 31 extending into the operating table 1, and the operating table 1 is provided with a stabilizing groove 32 that is sealingly and slidingly connected with the connecting rod 31. An elastic bellows 33 is arranged between the two rotating plates 8 , and the two ends of the elastic bellows 33 are respectively fixedly connected to the upper side walls of the two rotating plates 8 , and the elastic bellows 33 communicates with the stabilizing groove 32 through a conduit.

[0043] When in use, the initial height of the light box 4 is relatively low, which can make it easier for the staff to wind the cloth through the upper end of the light box 4 to the turning roller 3. When the console 1 rises, the gas in the elastic bellows 33 will Squeezed into the stable groove 32, further pushing the light box 4 to move upwards, the cloth can be graduall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com