Safety elevator landing door

A safety elevator and floor door technology, which is applied to elevators, transportation and packaging in buildings, etc., can solve the problems of ground impact damage, damage to the ground floor of the building, and affect the stability of the building, so as to strengthen the impact ability and improve the protection ability. , to avoid the effect of firmness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

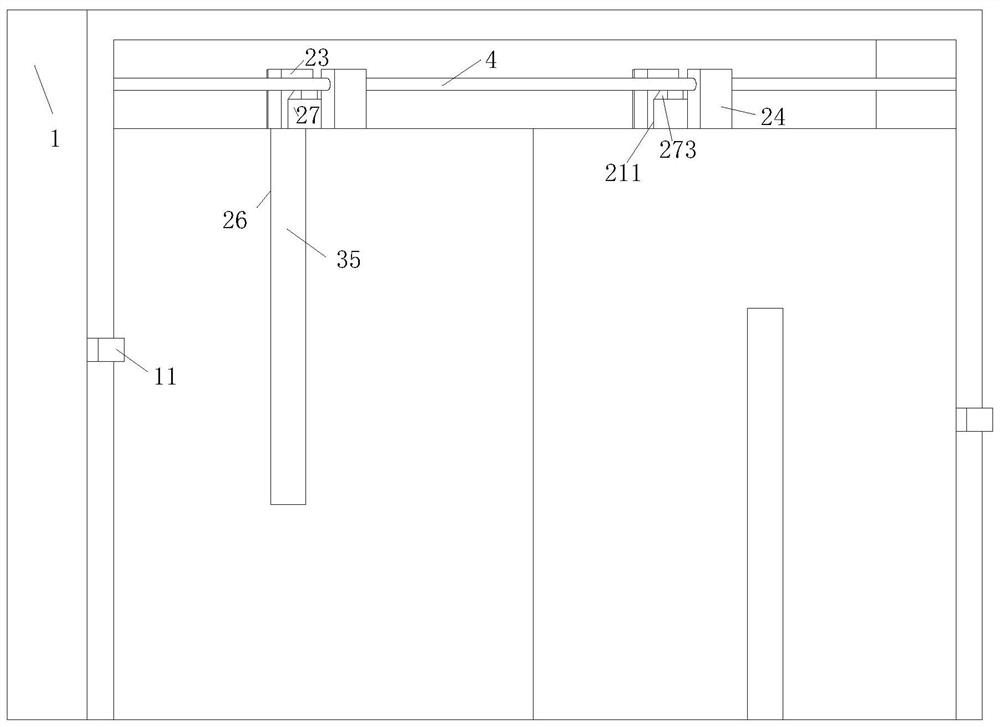

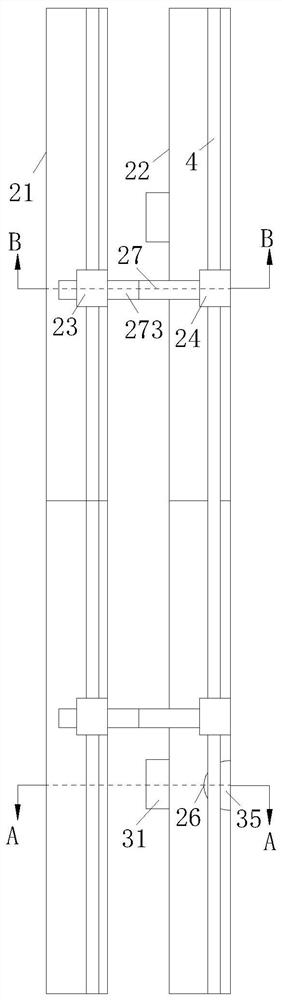

Image

Examples

Embodiment approach

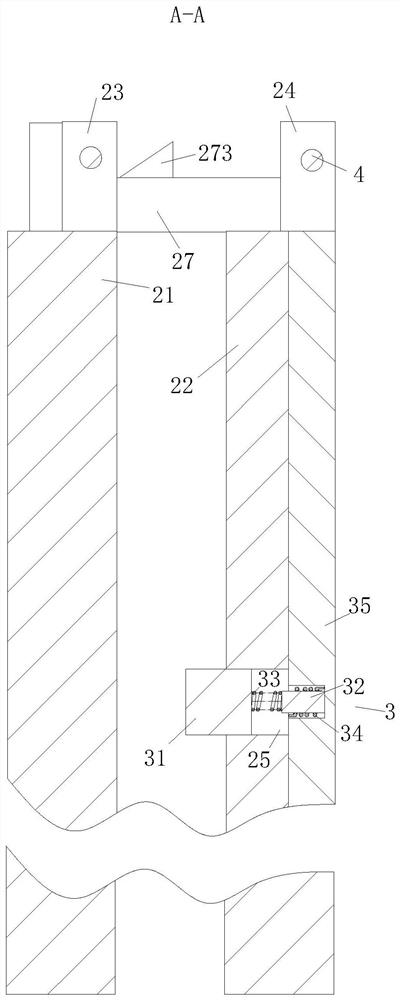

[0040] As an embodiment of the present invention, the pop-up interception module 3 includes a No. 1 displacement block 31, a No. 2 displacement block 32, a No. 1 spring 33, a torsion spring 34 and a rotating rod 35; the No. 1 displacement block 31 is slidably connected Inside No. 1 groove 25, No. 1 displacement block 31 stretches out No. 1 groove 25 near one end of No. 1 door body 21, No. 1 displacement block 31 and No. 2 displacement block 32 are connected by No. 1 spring 33; The end face of the No. 1 door body 22 away from the No. 1 door body 21 is provided with a No. 2 groove 26; the number of the No. 2 groove 26 is two, and the No. 2 groove 26 communicates with the No. 1 groove 25; the No. 2 groove The inside of the groove 26 is provided with a rotating rod 35; the rotating rod 35 is connected to the No. 2 displacement block 32 through the rotation of the torsion spring 34, and the rotating rod 35 is stuck in the No. 2 groove 26 in the initial state;

[0041] During work, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com