A kind of usb cable box feeding mechanism and its operation method

A technology of discharging mechanism and wire box, which is applied to conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of manpower consumption, large space occupation, large power consumption, etc. Material distribution efficiency, high lifting height effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

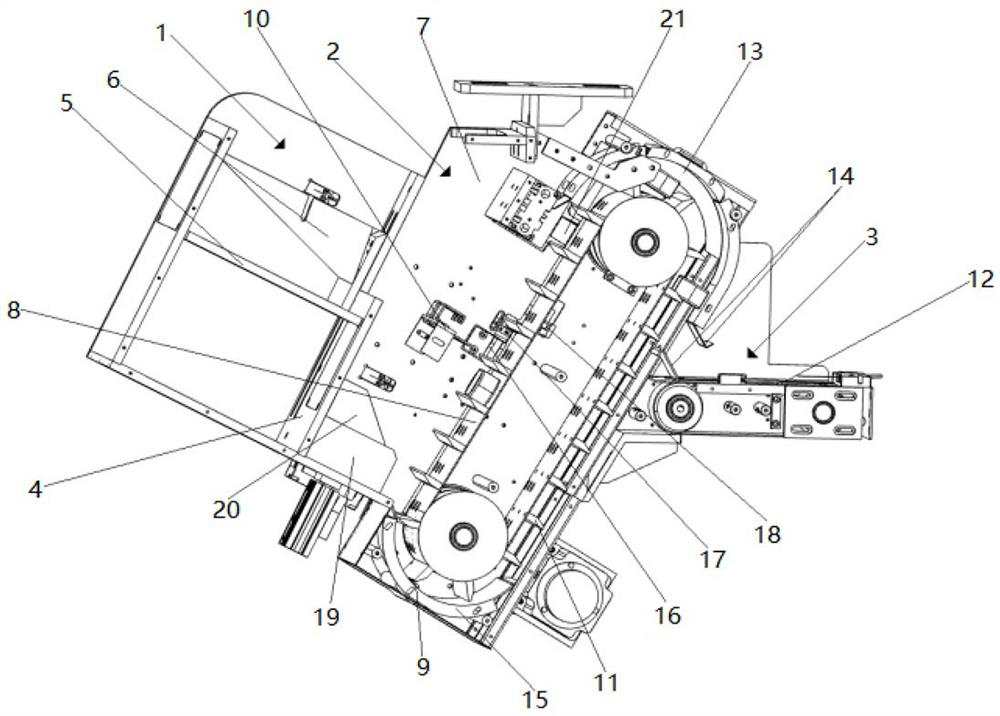

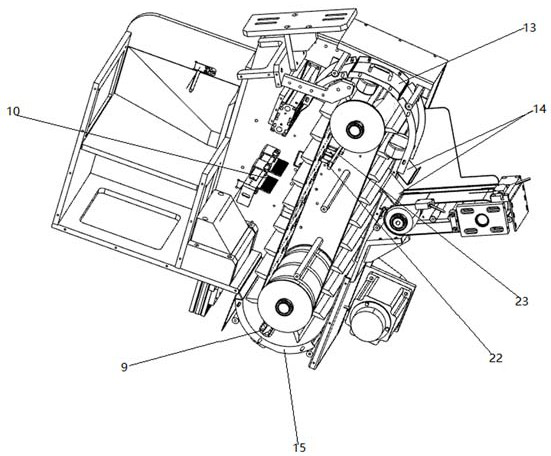

[0044] refer to Figure 1-Figure 4 , this embodiment mainly introduces a USB cable box feeding mechanism, including a feeding mechanism 1 , a lifting and distributing device 2 and a discharging mechanism 3 connected in sequence.

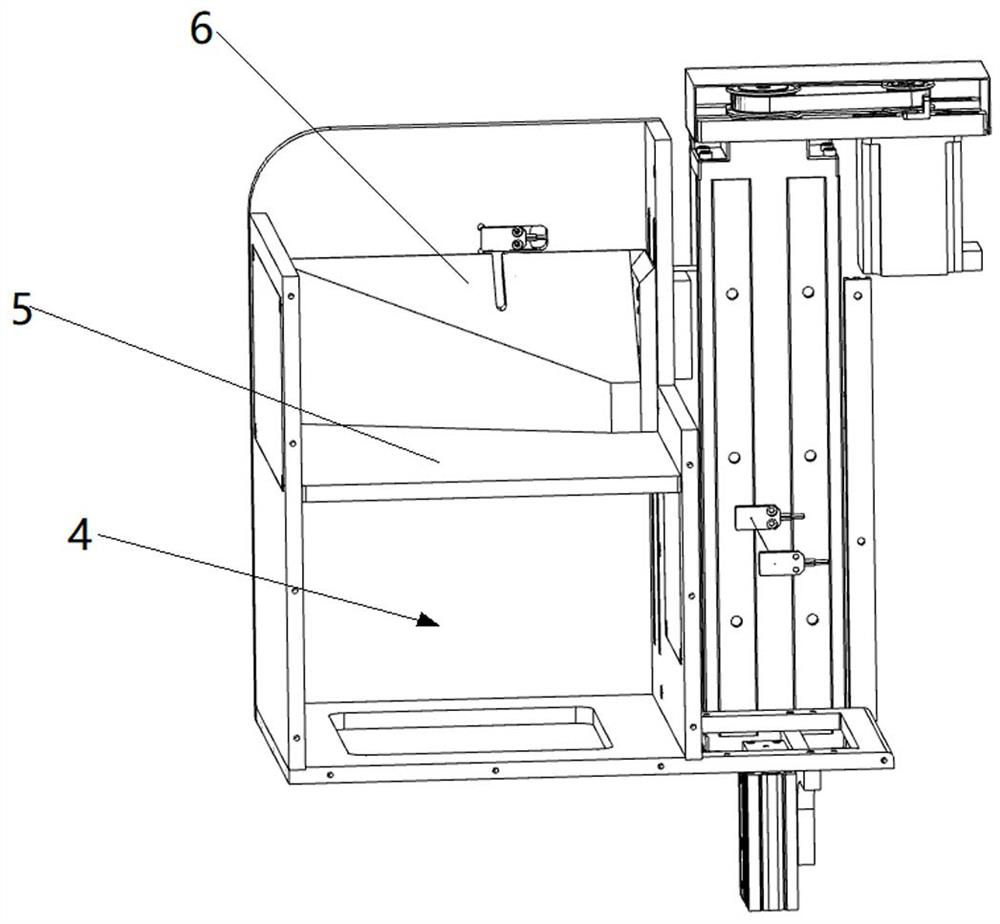

[0045] The loading mechanism 1 includes a storage bin 4, a loading platform 5 slidingly connected to the inner wall of the storage bin 4, and a sliding drive device for driving the loading platform 5 to slide up and down. The guide slope 6 of sliding connection, in order to realize better loading operation; When rising under the drive of the sliding drive device, the USB cable box falls from the loading platform 5 into the lifting and distributing device 2, thereby realizing feeding; the loading platform 5 is provided with a sensing device, when the loading platform 5 When the number of USB cable boxes continues to increase, the loading platform descends, and when the number of USB cable boxes on the loading platform decreases, the loading platform ...

Embodiment 2

[0053] This embodiment is improved on the basis of Embodiment 1, and the similarities will not be repeated; the differences include:

[0054] The distribution conveyor belt 8 forms an included angle 1 with the horizontal plane, and the degree of the included angle 1 is 0°-80°;

[0055] The loading platform 5 forms an included angle 2 with the distribution conveyor belt 8, and the degree of the included angle 2 is 70°-110°;

[0056] The slope of the second push block 20 forms an included angle 3 with the material distribution conveyor belt 8, and the degree of the included angle 3 is 30°-70°.

Embodiment 3

[0058] This embodiment mainly introduces the operation method of embodiment 1, and the steps are as follows:

[0059] Step 1, the static electricity generating device 9 discharges static electricity to the baffle plate 11;

[0060] Step 2, the USB cable box enters the loading platform 5, the sliding drive device drives the loading platform 5 to slide upward along the inner wall of the storage bin 4, and the USB cable box falls from the loading platform 5 to the bottom or the baffle of the lifting and distributing device 2 11 on;

[0061] Step 3, the baffle 11 drives the USB cable box to carry out the lifting operation;

[0062] Wherein said step 2 and step 3 also include: the auxiliary feeding device pushes the USB cable box to the material distribution conveyor belt 8;

[0063] Due to the adsorption force between the USB cable box and the baffle 11 with static electricity, the USB cable box will be adsorbed to the baffle 11; that is, when the USB cable box is falling, the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com