Lifting device for preventing concrete from dripping

A concrete and hoist technology, applied in the direction of supply devices, manufacturing tools, etc., can solve problems such as eye damage, hoisting device jamming, and easy sputtering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

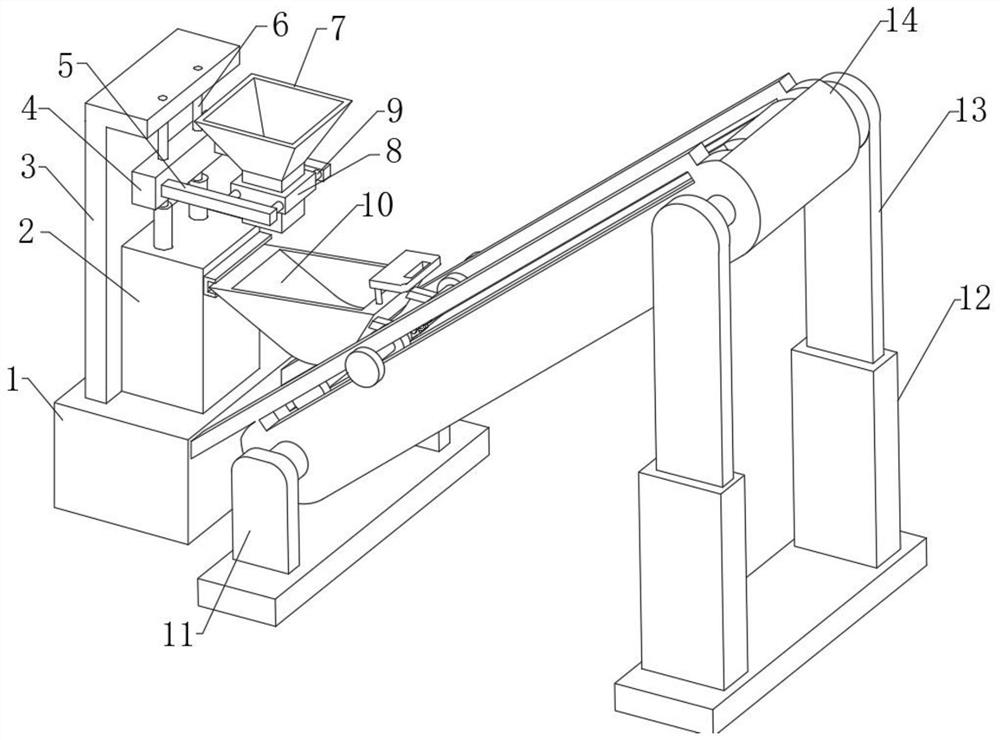

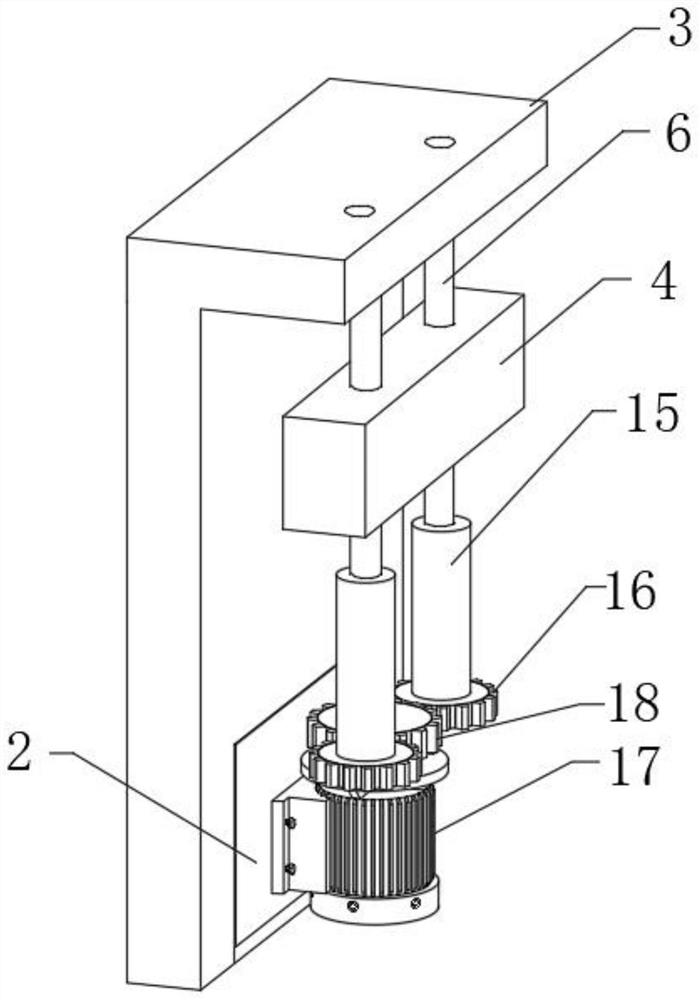

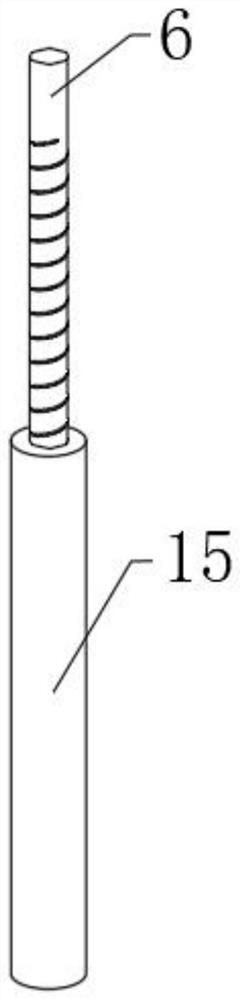

[0028]A lifting device for preventing concrete dripping, comprising a fixed base 1, characterized in that: the upper surface of the fixed base 1 is fixedly connected with a power bin 2, and one side of the outer surface of the power bin 2 is provided with a card slot block, and the outer surface of the power bin 2 The other side of the surface is fixedly connected with a fixed plate 3, the upper surface of the power bin 2 is provided with a lifting mechanism, one side of the outer surface of the fixed base 1 is fixedly connected with a hoist 14, and one end of the hoist is fixedly connected with a front support frame 11, The other end of the hoist 14 is fixedly connected with a lifting column 13, the lower surface of the lifting column 13 is fixedly connected with a rear support frame 12, and the upper surface of the hoist 14 is provided with a transport vehicle 10, and one end of the transport vehicle 10 is engaged with the movable block of the slot block. Then, the lifting me...

Embodiment 2

[0030] Embodiment 2: the difference based on Embodiment 1 is;

[0031] The inside of the hoist 14 is fixedly equipped with a motor 28, and one end of the motor 28 is fixedly connected with a starting shaft, and the outer surface of the starting shaft is fixedly connected with two winding wheels 29, and the inside of the winding wheel 29 is fixedly connected with a connecting belt 31, and the connecting belt 31 The outer surface of the middle part is movably connected with a sleeve wheel 32, and the upper surface of the hoist 14 is fixedly connected with a splint 30. The middle part of the splint 30 is provided with two strip holes, and the connecting belt 31 runs through the strip hole movably. The other end is fixedly connected with a socket wheel 32, the inner surface of the socket wheel 32 is movably socketed with a penetrating column 33, the outer surface of the penetrating column 33 is provided with a fixed shell 35, and the two sides of the fixed shell 35 are fixedly conn...

Embodiment 3

[0033] Embodiment 3: the difference based on embodiment 1 is;

[0034] The outer surface of movable shaft 19 is movably connected with bearing 26, and the outer surface of bearing 26 is fixedly connected with movable wheel 27, and the front surface of movable wheel 27 is fixedly connected with clamp post 36, and the other end of clamp post 36 is fixedly connected with limit wheel 37, The upper surface of the transport vehicle 10 is fixedly connected with a pull plate 25, the lower surface of the transport vehicle 10 is fixedly connected with a connecting column 23, the lower surface of the connecting column 23 is fixedly connected with a connecting shaft 24, and the two sides of the connecting shaft 24 are fixedly connected with rolling wheels. , the outer surface of movable shaft 19 is fixedly connected with connecting rod 20, and one end of connecting rod 20 is fixedly connected with fixed ring 21, and one side of transport vehicle 10 outer surface offers movable groove, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com