Control method of water chilling unit

A chiller and control method technology, applied in the direction of heating and ventilation control systems, heating methods, mechanical equipment, etc., can solve the problems of reduced comfort, increased power consumption of chillers, and fluctuations in outlet air temperature, so as to avoid power consumption The effect of volume increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

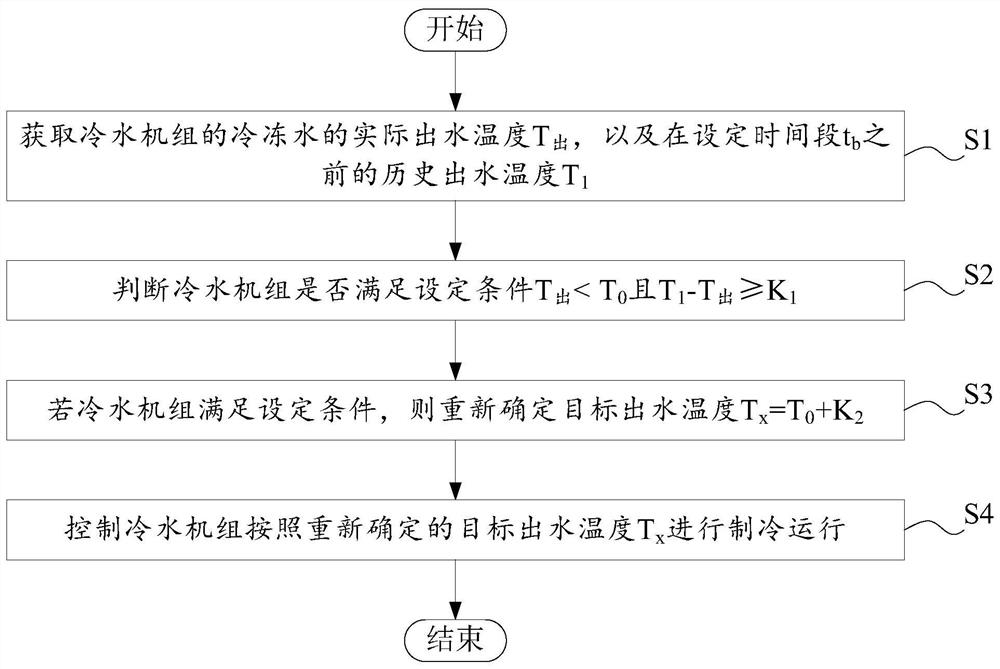

[0048]As a preferred implementation of the above-mentioned control method provided in this embodiment, it also includes the following steps: S101, obtaining the actual inlet water temperature T of the chilled water of the chiller 进 .

[0049] Before step S4, it also includes: S31, calculating the adjustment rate V of the target outlet water temperature of the chiller; wherein, V=(T 进 -T 出 )*(T 1 -T 出 )*K 3 ; The unit of V is ℃ / s, where K 3 is a constant;

[0050] Step S4 also includes: S41, controlling the target outlet water temperature of the chiller by T 0 To adjust the speed V to T x .

[0051] It should be noted that step S101 only needs to be executed before step S4. For example, step S101 may be executed synchronously with step S1, or may be executed after step S3.

[0052] In the control method of the water chiller provided in this embodiment, after re-determining the target outlet water temperature T x Afterwards, the adjustment rate V of the target outlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com