Low-steel-content ultra-large-span steel structure system based on high-precision plane truss

A plane truss, high-precision technology, applied in the direction of truss structures, girders, truss beams, etc., can solve problems such as inability to meet the requirements of the installation process, difficulty in meeting the requirements of super-large spans, and difficulty in the construction process, so as to reduce installation risks and improve work efficiency , Ease of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

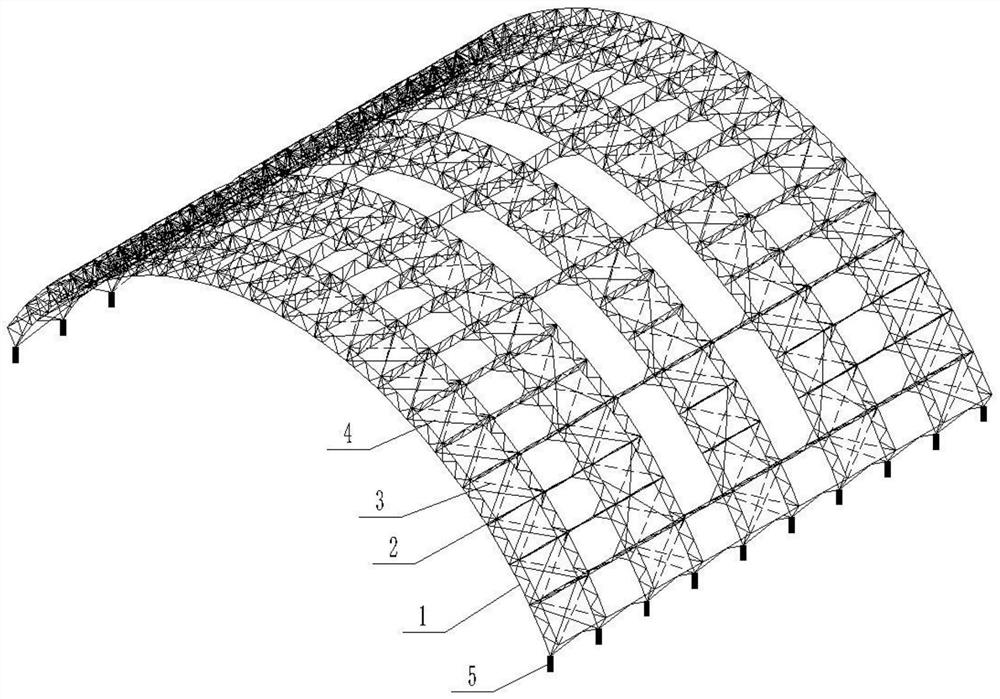

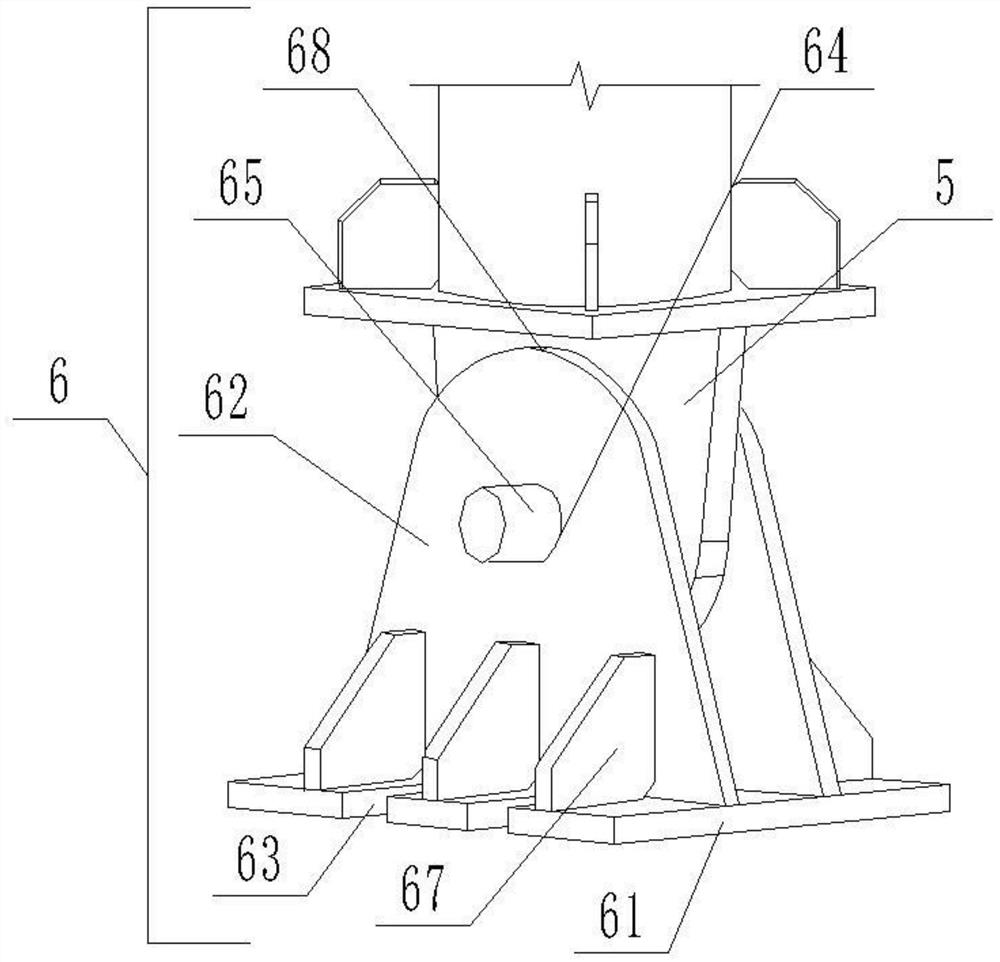

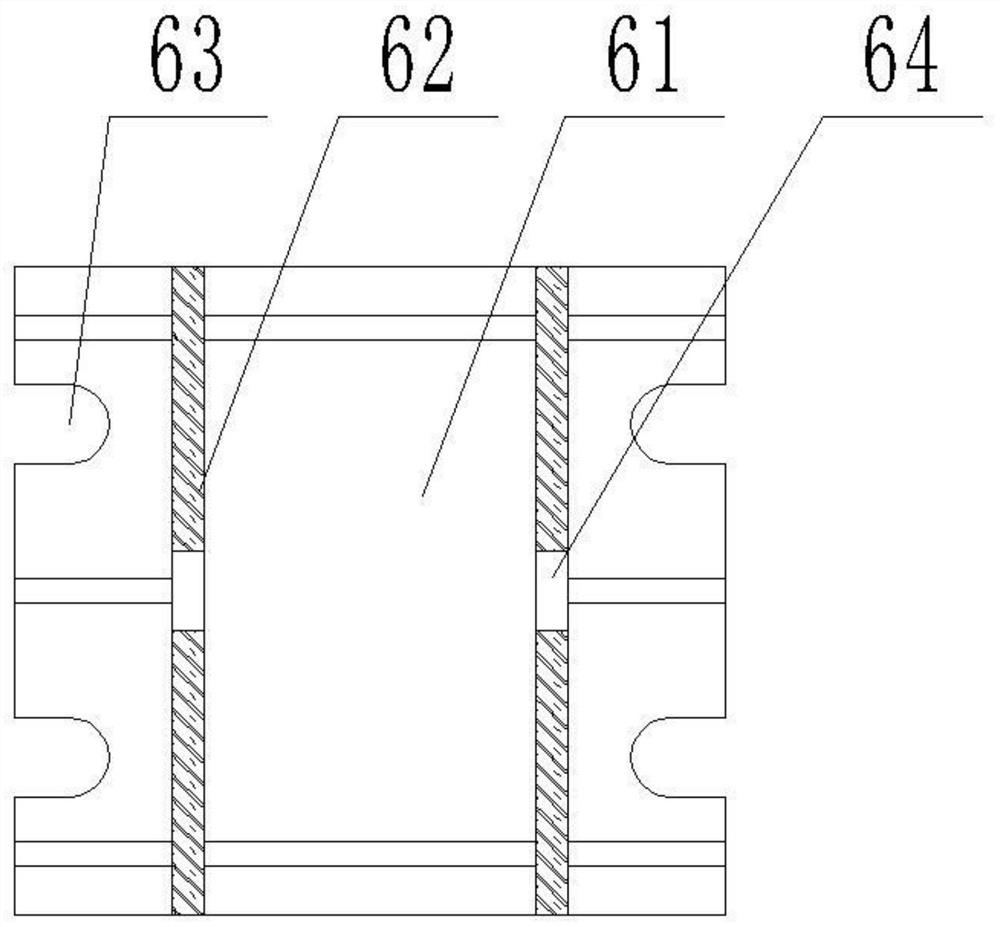

[0034] Such as Figure 1 to Figure 9 As shown, the present invention is a low-steel-content super-large-span steel structure system based on a high-precision plane truss, including a span 1, a longitudinal connecting frame 2, a flexible steel wire rope structure 4, a movable mounting seat 5, a guide rail 7 and a membrane 8, and more The two spans 1 are distributed in parallel and equidistant, and the span 1 includes an upper chord 11, a lower chord 12, a zero bar 13, a web 14 and a flange connecting plate 15, and the upper chord 11 and the lower chord 12 are arranged in parallel , and the upper chord 11 is located directly above the lower chord 12, and the upper chord 11 and the lower chord 12 are connected and fixed by multiple or obliquely arranged webs 14, or vertically arranged webs 14, and the upper chord The corresponding two ends of the rod 11 and the lower chord 12 are connected and fixed by the zero rod 13, and the two ends of the upper chord 11 and the lower chord 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com