Automatic press-fitting device for product embedded nuts

A technology of embedded nut and press-fitting device, applied in metal processing equipment, sorting, metal processing and other directions, can solve the problems of low installation efficiency, high defective rate, high labor intensity, etc., and achieve high work efficiency and solution efficiency. Low and labor-intensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

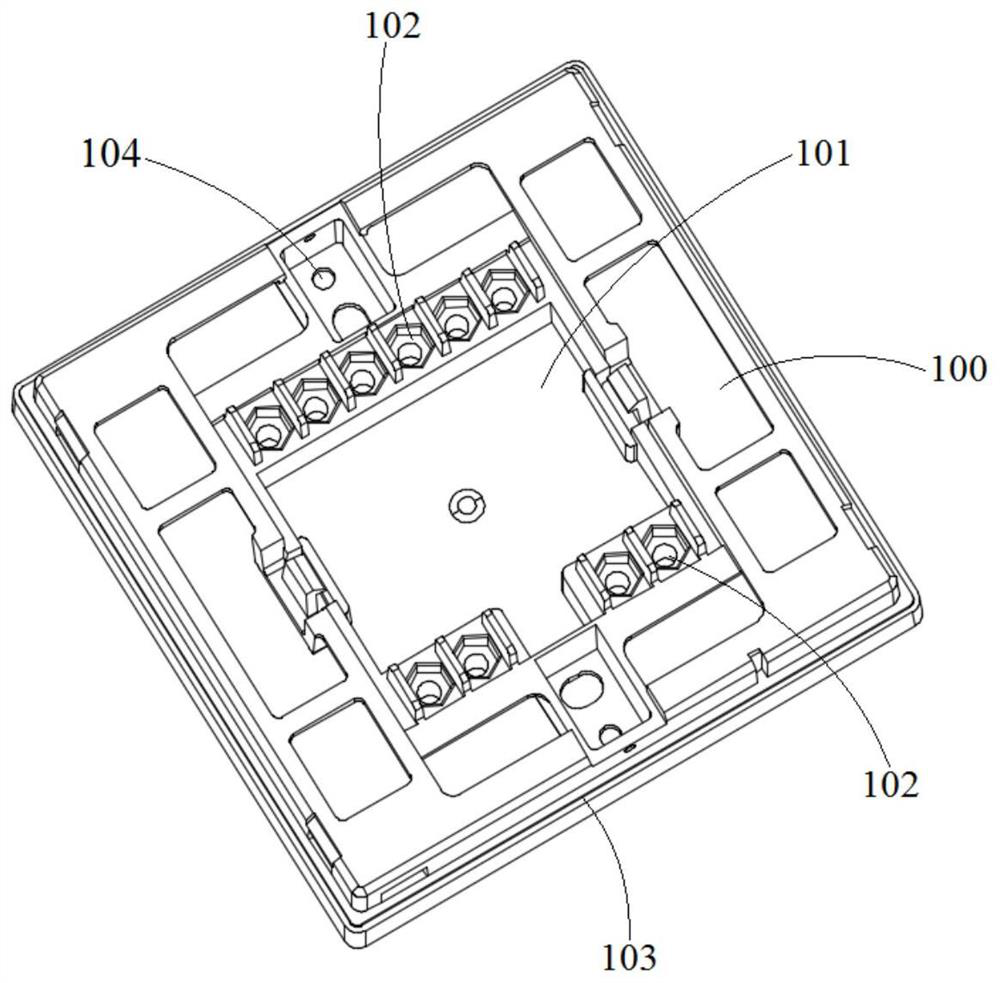

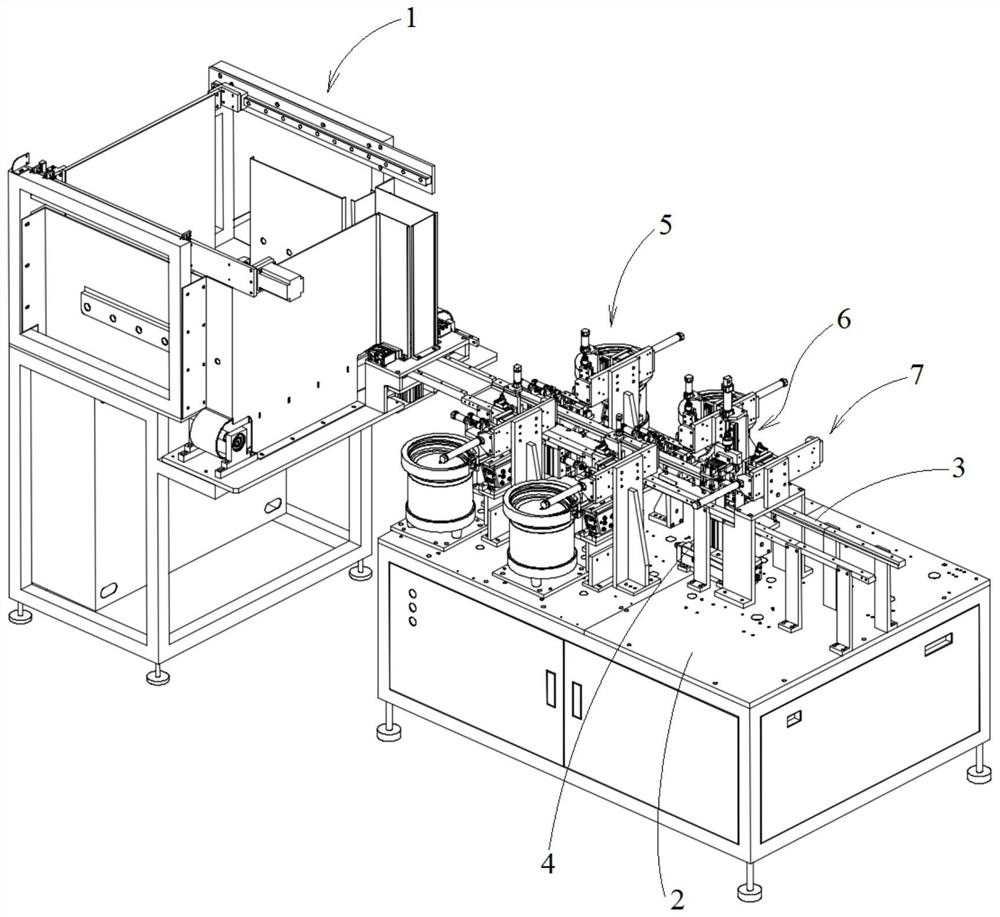

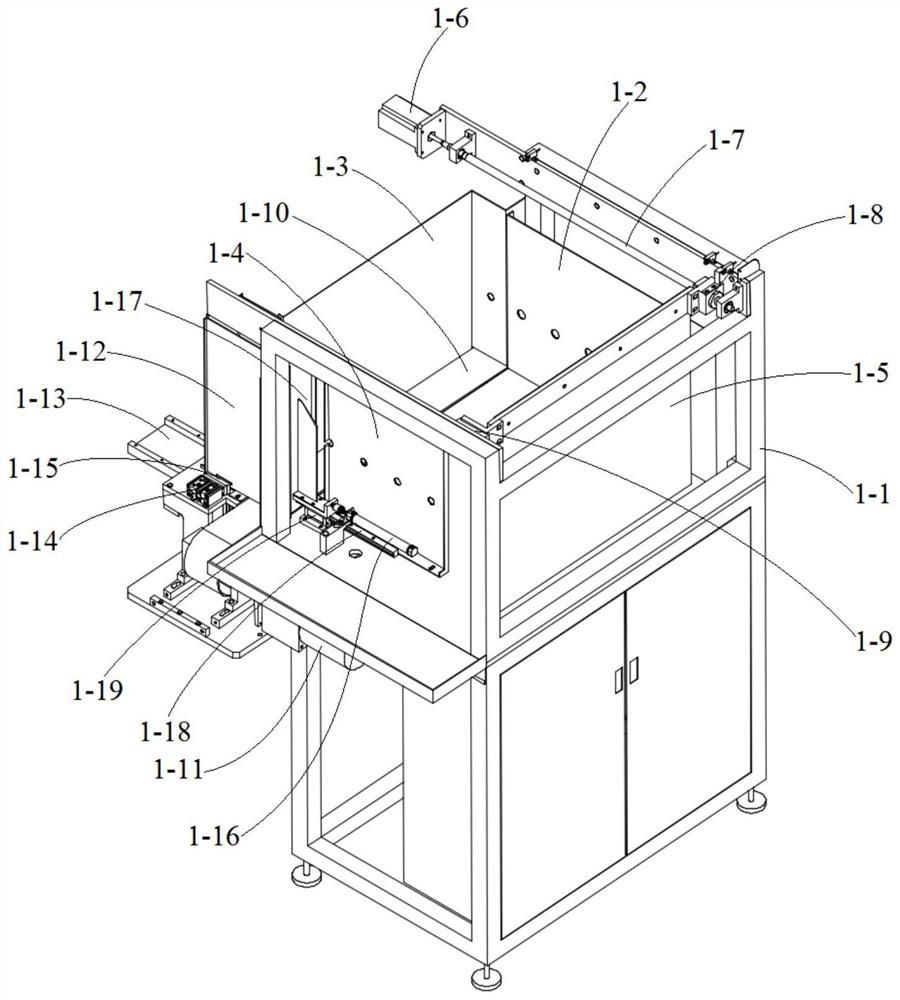

[0062] to combine figure 2 As shown, an automatic press-fitting device for a product embedded with nuts in this embodiment includes a product feeding mechanism 1, a workbench 2, a product delivery track 3, a product moving mechanism 4 and a nut feeding and pressing mechanism 5. The track 3 is erected horizontally on the workbench 2, and one end of the product delivery track 3 is connected to the discharge port of the product feeding mechanism 1, and the products sent by the product feeding mechanism 1 directly enter the product delivery track 3, and the product moving mechanism 4 It is located under the product conveying track 3, and is used to drive the product to move forward intermittently on the product conveying track 3, and the product is transported forward by the product moving mechanism 4 to realize the transfer of the product in each station; the product conveying track 3 is composed of Composed of two single tracks arranged in parallel, in order to prevent the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com