Intelligent industrial welding system

A welding system and industrial technology, applied in the direction of welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve the problems of reducing the work efficiency of the staff, shifting the fastening position of the processed parts, and reducing the welding efficiency of the device, etc., to achieve Improve the scope of application, avoid collisions, and prolong the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

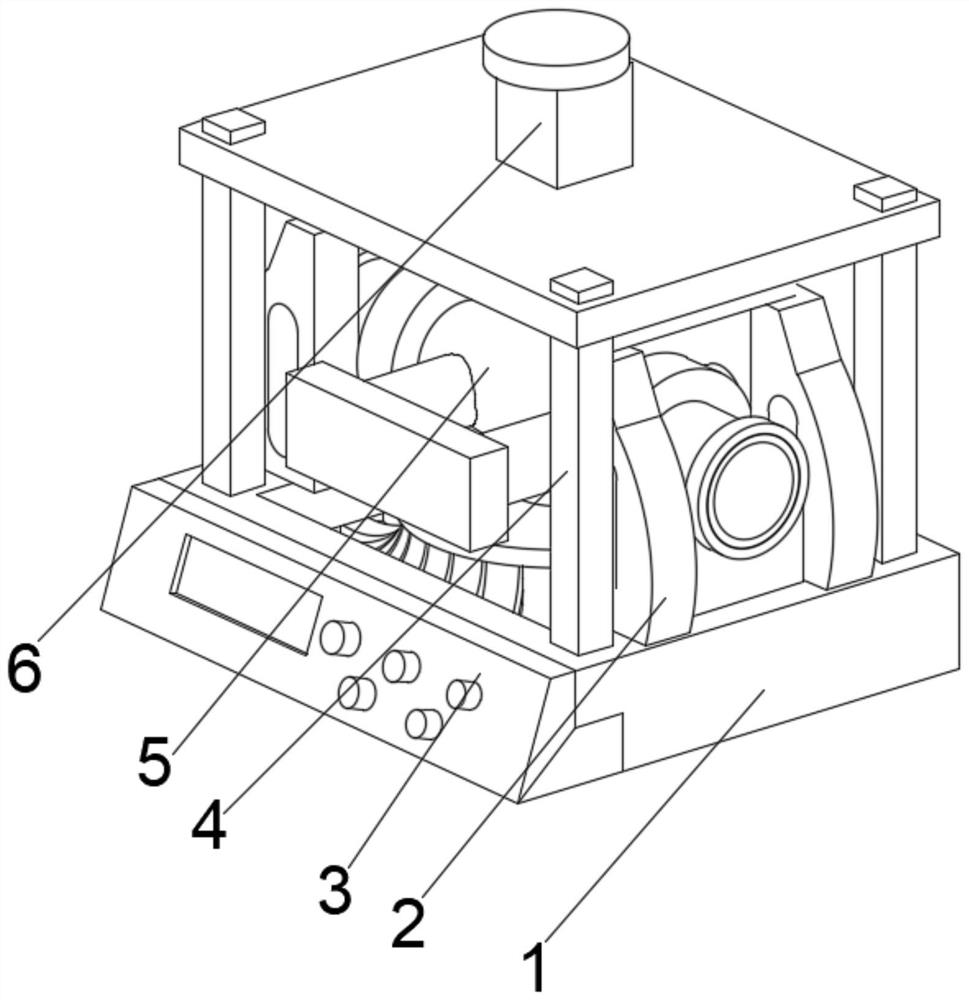

[0040] see Figure 1-6 , the present invention provides a technical solution: an intelligent industrial welding system, including a welding base 1, a control panel 3 is fixedly connected to the front top of the welding base 1, and a fixing frame 4 is fixedly connected to both sides of the top of the welding base 1, The middle position of the top of the fixed frame 4 is provided with a welder 6, the bottom of the welder 6 runs through the fixed frame 4 and extends to the outside of the fixed frame 4, the middle position of the inner cavity bottom of the welding base 1 is provided with a fastening device 5, and the welding base 1 The top of the fastening device 5 is fixedly connected with thickened side plates 2 on both sides.

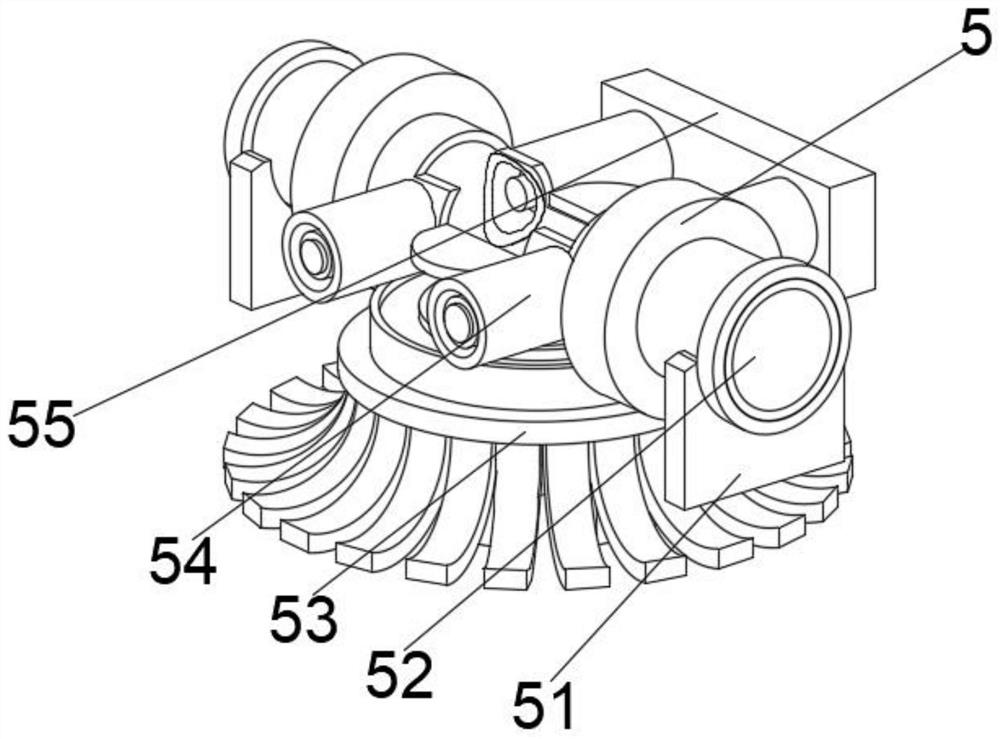

[0041] Wherein, the fastening device 5 includes a support plate 51, the top middle position of the support plate 51 is fixedly connected with a feed pipe 52, and the end of the feed pipe 52 away from the support plate 51 is provided with an adjustment me...

Embodiment 2

[0047] see Figure 1-6 , on the basis of Embodiment 1, the present invention provides a technical solution: a method for using an intelligent industrial welding system, step 1: place the device on a stable ground, connect the control panel 3 to the power supply, and connect the tight The fixing device 5 is connected and fixed with the workpiece, and the welder 6 is connected with the fixing frame 4 to make it fall vertically;

[0048] Step 2: Connect the feeding pipe 52 to the adjustment mechanism 54 through the support plate 51, and connect the transition mechanism 53 to the adjustment mechanism 54, so that the welding position can be adjusted inside;

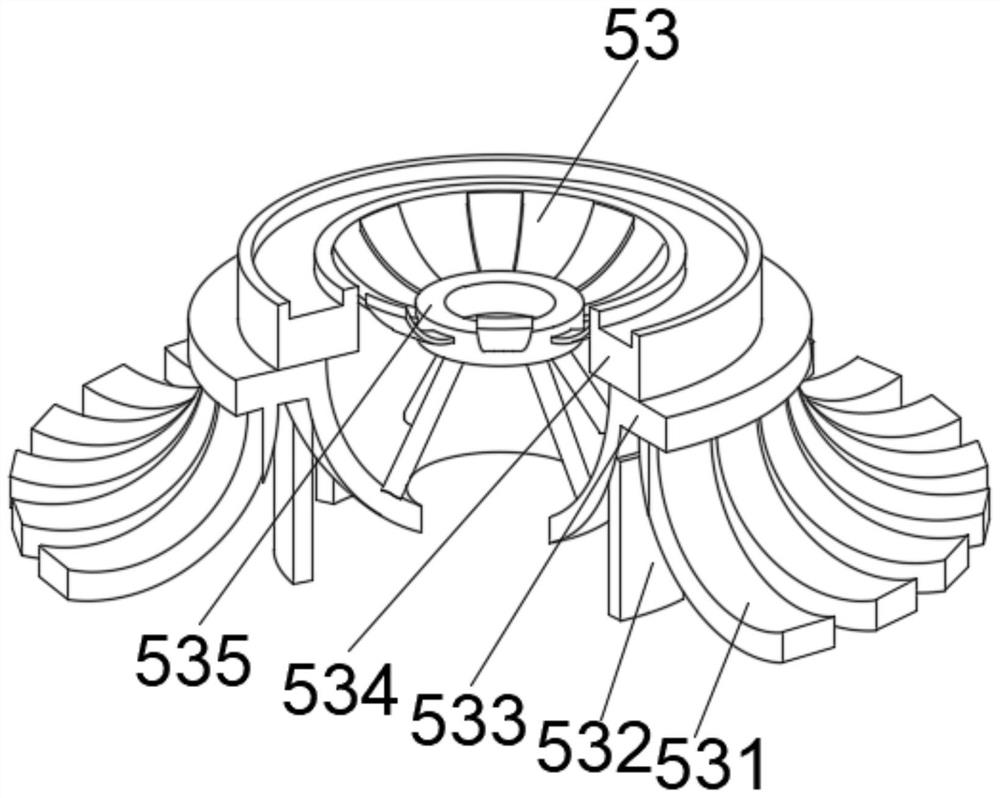

[0049] Step 3: insert the driver into the transition housing 533, make it contact with the installation frame 535, and fix it by using the communication groove formed by the insulating splint 532 and the transition housing 533, so that the arc-shaped side plate 531 can protect the fallen Debris is collected separately;

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com