Chamfering tool and chamfering equipment

A chamfering tool and chamfering technology, applied in milling machine equipment, milling machine equipment details, metal processing equipment and other directions, can solve the problems affecting the quality of the plate film, film pulling, etc. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

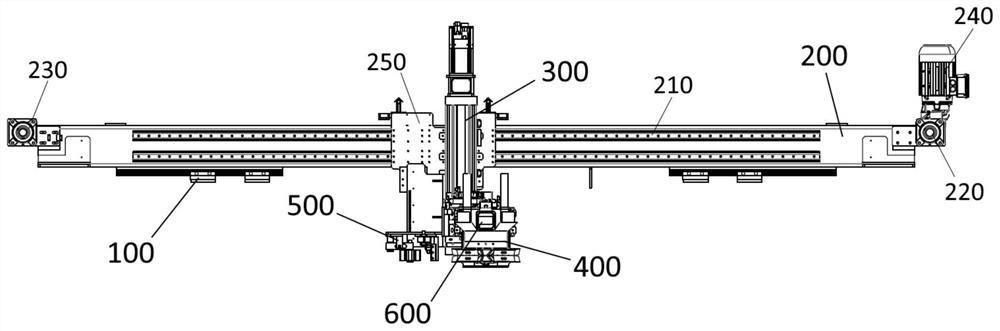

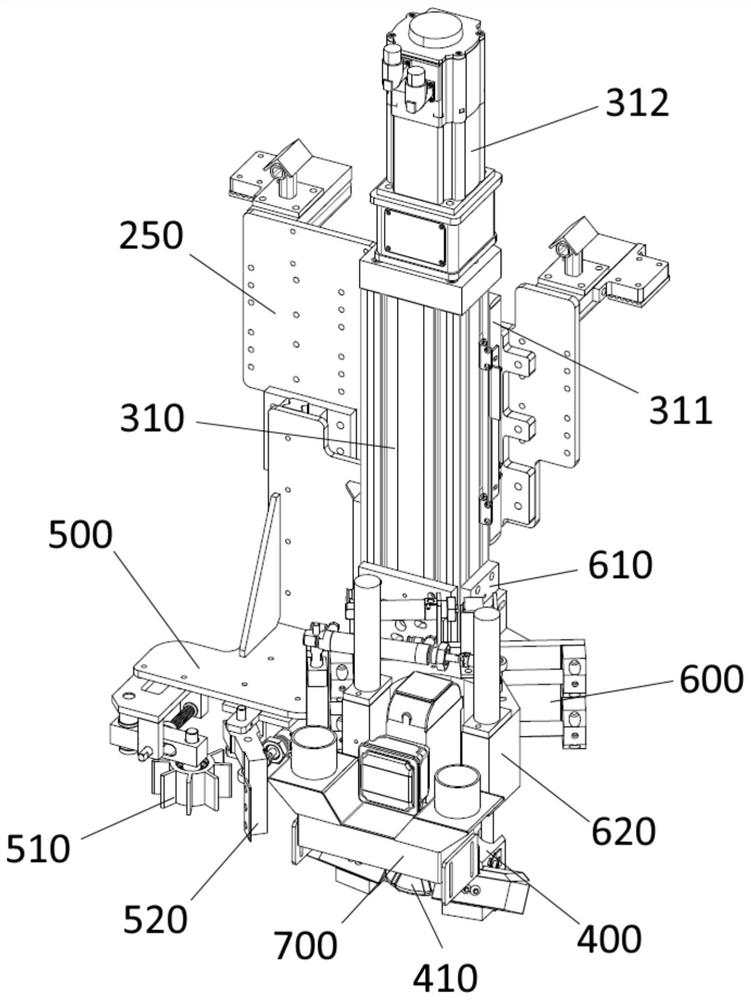

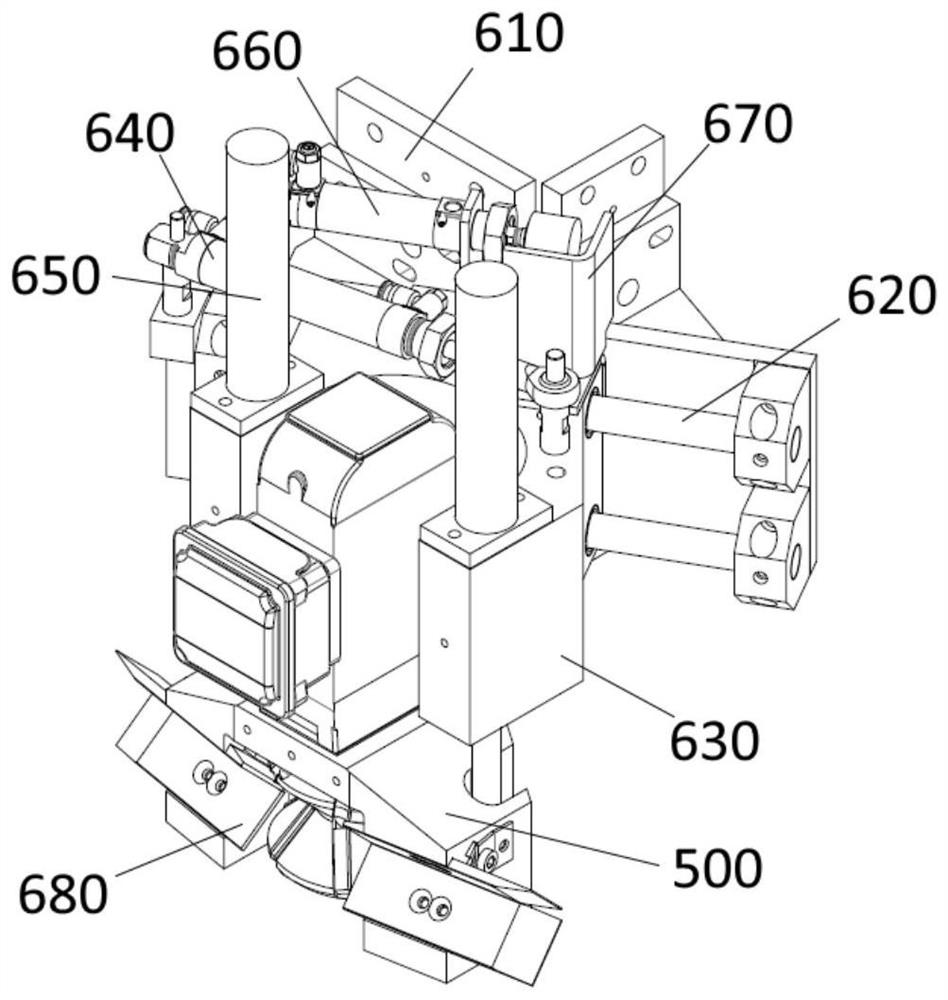

[0061] See attached Figures 1 to 5, a plate chamfering equipment, including: a frame 100, a traverse mechanism 200, a lifting mechanism 300, a third mounting seat 400, a tapered milling cutter 410, a fourth mounting seat 500, a shredding wheel 510, a scraper 520, a straight line Guide rail 210, driving wheel 220, driven wheel 230, first servo motor 240, first mounting plate 250, electric cylinder 310, slider 311, second servo motor 312, adaptive mechanism 600, first mounting base 610, guide post 620 , the second mounting seat 630 , the first cylinder 640 , the spring 650 , the second cylinder 660 , the limit plate 670 , the guide plate 680 , the bottom plate 631 , the side plate 632 , and the dust suction device 700 .

[0062] Among them, see the attached figure 1 , the frame 100 is used for installing chamfering equipment, and a workbench is provided at the bottom of the frame 100, and the workbench includes at least a positioning mechanism and a fixing mechanism for the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com