Tobacco arranging device for loading tobacco in barn and method of use thereof

A technology for loading and arranging tobacco, which is applied in the field of tobacco processing, which can solve the problems of cigarette drop and unsatisfactory loading effect, and achieve the effects of neatly arranged tobacco leaves, uniform dehydration speed, easy color fixing, and easy and labor-saving turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

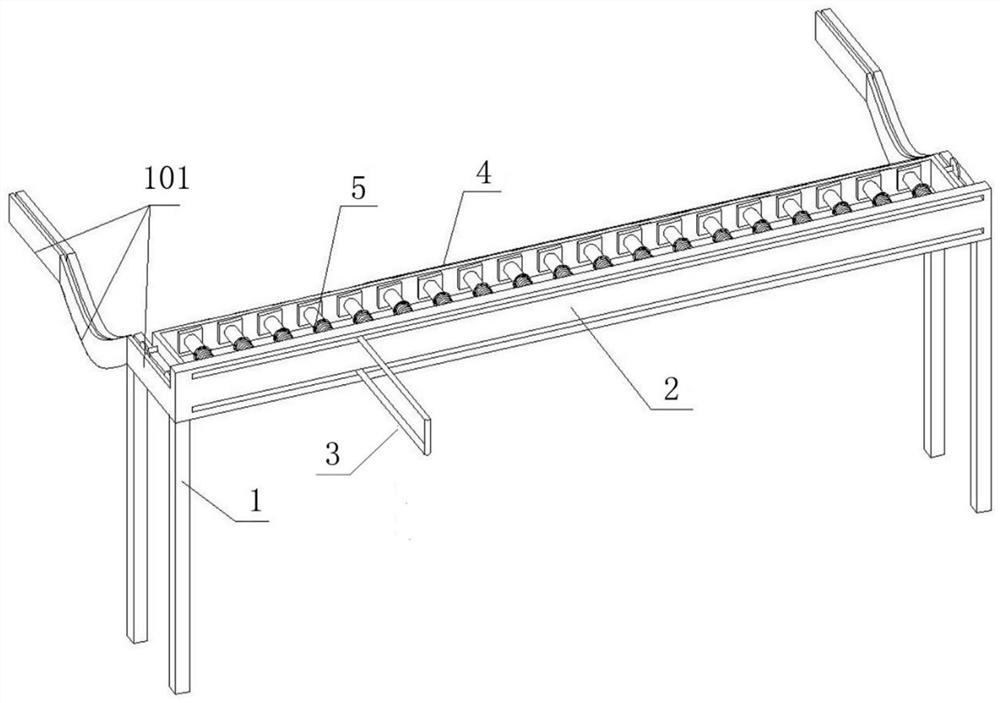

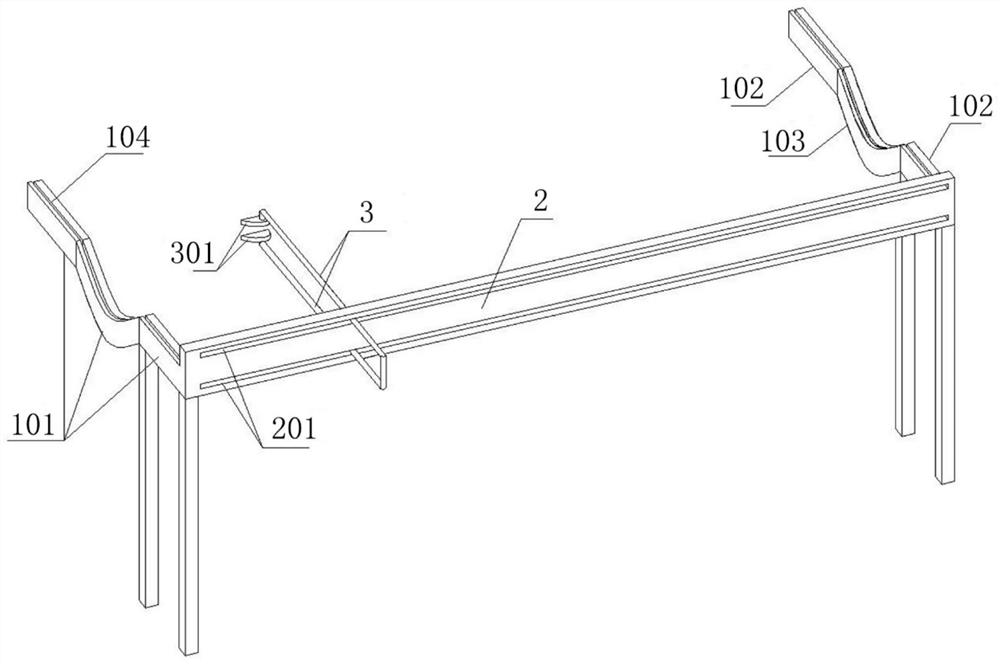

[0043] like Figures 1 to 3 As shown, this embodiment provides a cigarette management device for cigarette loading in a barn, the device includes a cigarette clip and a cigarette management mechanism; such as figure 2 As shown, the cigarette clip includes a frame 4 and several cigarette clipping mechanisms 5 arranged in the frame 4 . The frame 4 is a rectangular parallelepiped structure, and the several cigarette clipping mechanisms 5 are arranged at equal intervals along the length direction of the frame 4 . The cigarette clamping mechanism 5 includes a pressing sheet 501, a pull rod 502, a limit plate 503, a spring 504 and a convex top member 506. The pull rod 502 is arranged along the width direction of the frame 4, one end of the pull rod 502 is located in the frame 4, and the other end passes through the limiter in turn. The position plate 503 and the frame 4 are exposed to the outside of the frame 4; the vertical pull rod 502 of the pressing piece 501 is arranged at one...

Embodiment 2

[0053] The difference between this example and the first embodiment is that the frame 4 is provided with a pair of parallel second chute along its length direction near the outer side of the raised top member 506, the curved surface of the raised top member is embedded in the second chute, and the second slide On the one hand, the groove can limit the position of the convex top member 506 to prevent the convex top member 506 from rotating in the circumferential direction; Boss member 506 of each smoking mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com