Water dispersible granules and preparation method thereof

A technology of dispersing granules and dispersing agents, which is applied in the field of pesticides and can solve the problems of granule bonding, reducing the efficacy of boscalid and pyraclostrobin, and lowering the melting point, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

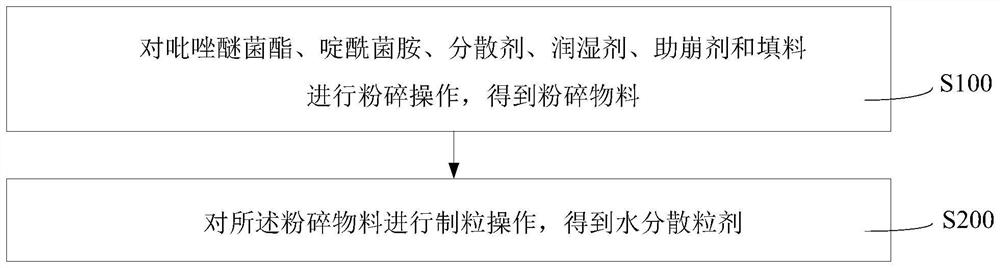

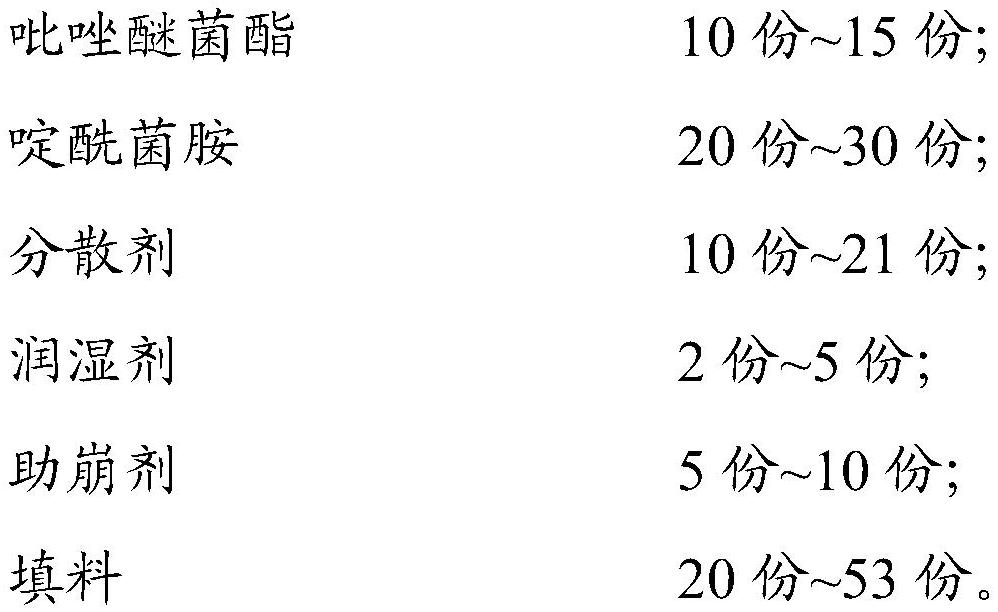

[0054] The application also provides a preparation method of the water-dispersible granule. The above-mentioned preparation method of water-dispersible granules is used to prepare the water-dispersible granules of any of the above-mentioned embodiments. The preparation method of the above-mentioned water-dispersible granules comprises the following steps: crushing pyraclostrobin, boscalid, dispersant, wetting agent, disintegration aid and filler to obtain corresponding crushed materials; crushing the crushed materials A granulation operation was performed to obtain water-dispersible granules.

[0055] In the preparation method of the above-mentioned water-dispersible granules, pyraclostrobin, boscalid, dispersant, wetting agent, disintegration aid and filler are pulverized to obtain corresponding pulverized materials, and the dispersant, pyrimidine The dispersion uniformity of pyraclostrobin and boscalid is conducive to improving the coating effect of the dispersant on pyracl...

Embodiment 1

[0075] 10kg pyraclostrobin, 20kg boscalid, 5kg 2700, 5.5kg Reax 910, 2kg YUS-SXC, 5kg ammonium sulfate, 10kg sodium citrate and 42.5kg corn starch were respectively pulverized to obtain corresponding pulverized materials use;

[0076] Mix the pulverized Reax 910, pyraclostrobin and boscalid, and add water for thorough mixing to obtain a mixture;

[0077] Add the crushed 2700 to the mixture and mix thoroughly;

[0078] Add YUS-SXC, ammonium sulfate, sodium citrate and cornstarch to the mixture and mix thoroughly to obtain a water-humidified mixture;

[0079] Extrusion granulation and drying are performed on the water-humidified mixture to obtain water-dispersible granules.

Embodiment 2

[0081] 13kg of pyraclostrobin, 25kg of boscalid, 5kg of D500, 10kg of Ufoxane 3A, 3kg of Terwet1004, 7kg of anhydrous sodium sulfate and 37kg of corn starch were respectively pulverized to obtain corresponding pulverized materials for use;

[0082] Mix the pulverized Ufoxane 3A, pyraclostrobin and boscalid, and add water for thorough mixing to obtain a mixture;

[0083] Add the crushed D500 into the mixture for thorough mixing;

[0084] Add Terwet1004, anhydrous sodium sulfate and cornstarch into the mixture for thorough mixing to obtain a water-humidified mixture;

[0085] Extrusion granulation and drying are performed on the water-humidified mixture to obtain water-dispersible granules.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com